Electrical and Computer Engineering Design Handbook

An Introduction to Electrical and Computer Engineering and Product Design by Tufts ECE Students

Problem Identification in Engineering Design

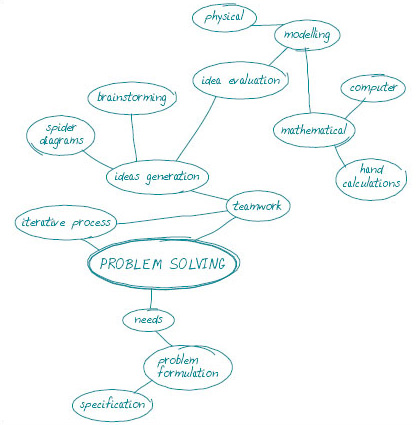

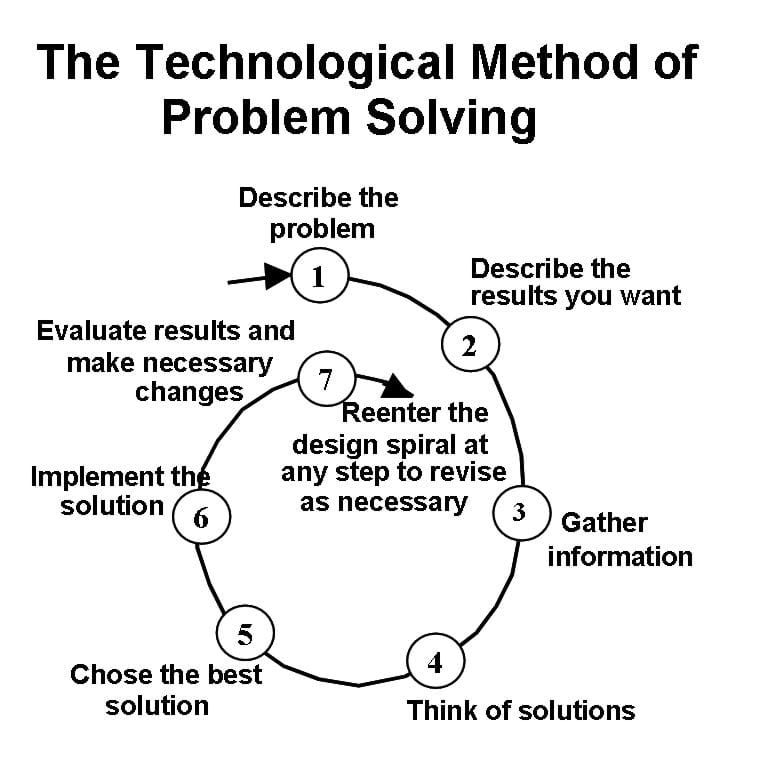

Problem identification is the first step of the engineering problem solving method. The relevant themes, processes and techniques for electrical engineering and their application to the senior design project are presented here.

Theory and Background

Engineering is a profession of applied science. Engineers must creatively find new ways to solve problems, and are always real-world problems. As a result, they are usually more complex than most problems studied in school, since many of the assumptions that are made to illustrate a concept are no longer valid. Yet, engineers still must come up with some solution. With so many new factors to consider when forming a solution, the entire process may seem daunting. In this way, one of the most critical steps in the problem solving process is solid problem identification. By effectively identifying the exact problem, and engineer may limit his or her focus to only the factors required to solve that problem (Shaw, 2001).

When inexperienced students go about the problem solving process, there are several paths they might take. For example, suppose students are building some type of robot. They have wired all their circuits together, but upon testing the robot, it simply does not work. The worst path they could take in this problem solving situation is to place all the blame upon factors out of their control. “The wires we have are faulty, so there is nothing we can do.” While this might be the case, it should be the last resort, as it leads to giving up on all prior work.

More motivated students might check several parts of their design and tinker with it until it works. This ad-hoc method is most common. The students can recall different ideas they have heard might cause problems, and check each one sequentially until a solution is found. In this manner, the problem identification is melded directly to the solution, as finding the latter leads to discovering the former. The difficulty with this ad-hoc method is that it varies with each project, so a more general system to fix problems cannot be extracted from this.

The best students may look at generalized problem solving methods that have been studied and improved upon for decades, and find a way to apply it to their project. This is the path that we will examine, and to do so, we will look at several example methods.

Common Themes

The similarities among the problem solving methods can be seen across many industries, especially business. Even with no scientific or technical aspects to a situation, the same ideas identify the problems effectively. One main cause for the similarities is the desire in business and other fields to have a rigorous methodology aimed at improving the target idea, project, company, etc.

To look at some common themes in problem solving methods, we will compare four widely used techniques: the TRIZ method, Root Cause Failure Analysis, and the two methods described in How to Solve It by Pólya (1957).

TRIZ Method

TRIZ, which is a Russian acronym for Theory of Inventive Problem Solving , is a problem solving method based on the study of patterns in problems and solutions. The developers of this method have analyzed over three million inventions with the intent of predicting where breakthroughs will come from (Jugulum & Samuel, 2008). The idea is that problems and solutions are repeated across a wide variety of applications, so by generalizing the problem, one can find a proven solution. Once the abstracted problem has been solved, the solution must then be adapted to the specific situation.

This method, like many other problem solving methods, is an iterative process. Identifying the problem is the first step. Once all the TRIZ analysis tools have been used and a solution has been identified, the process cycles back to identification again. Any new factors that arise from the initial solution must be addressed and attacked in the same manner as the original situation.

The main tool of classical TRIZ analysis for problem definition is the contradiction matrix. The axes of the matrix are engineering parameters, and potential general solutions are filled in the boxes. When one solution leads to a larger problem, a contradiction is identified. Kutz describes the tool:

The objective of the matrix is to direct the problem-solving process to incorporate an idea that has been utilized before to solve an analogous ‘‘inventive’’ problem. The contradiction matrix accomplishes this by asking two simple questions: Which element of the system is in need of improvement? If improved, which element of the system is deteriorated?” (Kutz, 2006, p. 622)

This is a useful tool if the design process is certain to be a long and iterative one. By going through such exhaustive planning and searching in the beginning, one can cut down many iterations in the process. However, the tool falls short if the scope is problem. It simply may not be necessary to write out the entire matrix for a problem that has only a few clear parameters to it.

Root Cause Failure Analysis

In reliability engineering and quality control, the main objective is to deal with problems and failures. It seems clear that a systematic approach to identifying the problem would arise in this field. This is the aim of Root Cause Failure Analysis (RFCA) (Mobley, 1999). The main idea is to identify the root cause of the problem that arises and eliminate it, as opposed to waiting for effects and mitigating them. It is analogous to getting vaccinated for the flu instead of waiting to catch it and then buying tissues.

There are several analysis techniques used in RFCA. These include Failure Mode and Effects Analysis, Cause and Effect Analysis, also known as fishbone analysis, and Sequence of Events Analysis. The applicability of each technique depends on what type of problem is present and what you want to focus on. For example, when the problem arose over time, the sequence analysis might be best. Alternatively, when you just want to lay out all possible causes without giving weight to any, the fishbone analysis is useful. A diagram of fishbone analysis is shown in Figure 1.

Fishbone Analysis.

The main issue unique to RFCA is the high cost of performing such an analysis (Mobley,1999). This means it should be used only when it is absolutely necessary. Also, it is somewhat limited in scope, as it was originally designed for use in chemical plant analysis.

How to Solve It

The book How to Solve It , written in 1957 by mathematician George Pólya, gives the methods used to solve many math problems and abstracts them to general problems. He generally describes the steps as understanding the problem, making a plan, carrying it out, and analyzing.

One of the most useful ideas he puts forth that is widely used in mathematics is to find an analogous problem and solve it. This is more useful in the extremely abstract world of mathematics where assumptions always hold true and objects are perfect, but the technique can be used to get a good approximation of a real world problem. In the world of engineering, this may be sufficient to get the job done.

While the techniques outlined in the book are very interesting to me as a mathematician, there are times when the methods can fall short. It is good practice to see how rigorous problem identifications and solutions can be generalized, but that is the majority of what the method does. To go out and solve your specific problem, there are still many specific connections to be made.

Application to Senior Project

The problem identification process is critical to the senior design project’s success. Before any design, implementation, or even productive planning can be done, the central problems behind the project must be laid out. This process goes hand in hand with identifying customer specifications. It is always critical to know precisely what the customer wants; however, in the ECE senior design projects , where student have essentially no prior experience, this step should get special care. See Ulrich & Eppinger (2004) for more information on customer specifications.

Once the customer’s needs and desires have been finalized, the problem identification may begin. There will almost certainly be multiple areas of the project that have a main problem. As you look at all the items the customer has suggested or demanded, you may find contradicting qualities. Here is where breaking the problem down to its most basic form is crucial. Only then can engineering decisions be made about which areas to compromise for the good of the whole project.

While the customer specification process only should occur once, the problem identification occurs many times as the design process is iterated. For example, in the Red Team’s senior project , which involved modifying a Parrot AR Drone toy helicopter to be able to autonomously collect data, the first major problem was finding usable and inexpensive hardware to add (Video 1). Once that had been solved, the next problem area was designing software that would allow the drone to hover stably at a target. Initially these two problems appeared to be the largest challenges; however, upon completing preliminary testing, it was discovered that no matter how sophisticated the stabilizing algorithm became, the helicopter would not remain very stable. As a result, the problem solving branched out in a direction previously unexpected. The process of identifying this new problem led to a workable solution.

The Red Team’s autonomous drone project navigating and gathering data. Source: Tufts SPARTN Channel on YouTube.com.

Cited References

- Jugulum, R., & Samuel, P. (2008). Design for Lean Six Sigma – A Holistic Approach to Design and Innovation . Hoboken: John Wiley & Sons. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/637224080

- Kutz, M. (2006). Mechanical Engineers’ Handbook – Materials and Mechanical Design (3rd ed.). Hoboken: John Wiley & Sons. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/59003354

- Mobley, R.K. (1999). Root Cause Failure Analysis . Boston: Newnes/Elsevier. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/40255833

- Pólya, G. (1957). How to Solve It . Garden City, NY: Doubleday. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/523312

- Shaw, M. C. (2001). Engineering Problem Solving – A Classical Perspective . Norwich: William Andrew Publishing/Noyes. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/633151037

Additional Sources / Recommended Reading

- Ulrich, K. T. & Eppinger, S. D. (2004). Product Design and Development . Boston/New York: McGraw-Hill/ Irwin. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/122424997

- ← Fuzzy Front-End

- Intellectual Property →

Disclaimer | Non-Discrimination | Privacy | Terms for Creating and Maintaining Sites

- Oct 13, 2019

10 Steps to Problem Solving for Engineers

Updated: Dec 6, 2020

With the official launch of the engineering book 10+1 Steps to Problem Solving: An Engineer's Guide it may be interesting to know that formalization of the concept began in episode 2 of the Engineering IRL Podcast back in July 2018.

As noted in the book remnants of the steps had existed throughout my career and in this episode I actually recorded the episode off the top of my head.

My goal was to help engineers build a practical approach to problem solving.

Have a listen.

Who can advise on the best approach to problem solving other than the professional problem solvers - Yes. I'm talking about being an Engineer.

There are 2 main trains of thought with Engineering work for non-engineers and that's trying to change the world with leading edge tech and innovations, or plain old boring math nerd type things.

Whilst, somewhat the case what this means is most content I read around Tech and Engineering are either super technical and (excruciatingly) detailed. OR really riff raff at the high level reveling at the possibilities of changing the world as we know it. And so what we end up with is a base (engineer only details) and the topping (media innovation coverage) but what about the meat? The contents?

There's a lot of beauty and interesting things there too. And what's the centrepiece? The common ground between all engineers? Problem solving.

The number one thing an Engineer does is problem solving. Now you may say, "hey, that's the same as my profession" - well this would be true for virtually every single profession on earth. This is not saying there isn't problem solving required in other professions. Some problems require very basic problem solving techniques such is used in every day life, but sometimes problems get more complicated, maybe they involve other parties, maybe its a specific quirk of the system in a specific scenario. One thing you learn in engineering is that not all problems are equal. These are

The stages of problem solving like a pro:

Is the problem identified (no, really, are you actually asking the right question?)

Have you applied related troubleshooting step to above problem?

Have you applied basic troubleshooting steps (i.e. check if its plugged in, turned it on and off again, checked your basics)

Tried step 2 again? (Desperation seeps in, but check your bases)

Asked a colleague or someone else that may have dealt with your problem? (50/50 at this point)

Asked DR. Google (This is still ok)

Deployed RTFM protocol (Read the F***ing Manual - Engineers are notorious for not doing this)

Repeated tests, changing slight things, checking relation to time, or number of people, or location or environment (we are getting DEEP now)

Go to the bottom level, in networking this is packet sniffers to inspect packets, in systems this is taking systems apart and testing in isolation, in software this is checking if 1 equals 1, you are trying to prove basic human facts that everyone knows. If 1 is not equal to 1, you're in deep trouble.At this point you are at rebuild from scratch, re install, start again as your answer (extremely expensive, very rare)

And there you have it! Those are your levels of problem solving. As you go through each step, the more expensive the problem is. -- BUT WAIT. I picked something up along the way and this is where I typically thrive. Somewhere between problem solving step 8 and 10.

The secret step

My recommendation at this point is to try tests that are seemingly unrelated to anything to do with the problem at all.Pull a random cable, test with a random system off/on, try it at a specific time of the day, try it specifically after restarting or replugging something in. Now, not completely random but within some sort of scope. These test are the ones that when someone is having a problem when you suggest they say "that shouldn't fix the problem, that shouldn't be related" and they are absolutely correct.But here's the thing -- at this stage they have already tried everything that SHOULD fix the problem. Now it's time for the hail mary's, the long shots, the clutching at straws. This method works wonders for many reasons. 1. You really are trying to try "anything" at this point.

2. Most of the time we may think we have problem solving step number 1 covered, but we really don't.

3. Triggering correlations.

This is important.

Triggering correlations

In a later post I will cover correlation vs causation, but for now understand that sometimes all you want to do is throw in new inputs to the system or problem you are solving in order to get clues or re identify problems or give new ways to approach earlier problem solving steps. There you have it. Problem solve like a ninja. Approach that extremely experienced and smart person what their problem and as they describe all the things they've tried, throw in a random thing they haven't tried. And when they say, well that shouldn't fix it, you ask them, well if you've exhausted everything that should have worked, this is the time to try things that shouldn't. Either they will think of more tests they haven't considered so as to avoid doing your preposterous idea OR they try it and get a new clue to their problem. Heck, at worst they confirm that they do know SOMETHING about the system.

Go out and problem solve ! As always, thanks for reading and good luck with all of your side hustles.

If you prefer to listen to learn we got you covered with the Engineering IRL show!

For Youtube please go to:

https://youtu.be/EHaRNZhqmHA

For Spotify please go to:

https://open.spotify.com/show/3UZPfOvNwQkaCA1jLIOxp4

And don't forget to subscribe if you get any value from the Engineering IRL Content

- Technical Tactics

- 10+1 Steps to Problem Solving

Recent Posts

How to Implement OSHA’s Requirement of Emergency Medical Services in Construction

Preventing Noise-Induced Issues in Construction

The Advantages of CAD for Modern Engineers

Get your free Engineering Toolkit for Engineering IRL listeners only

Get a copy of the Operational Technology Ultimate Guide for Engineers e-book for free.

Kaleidoscope: Educator Voices and Perspectives

- About Kaleidoscope

- Current Issue

- Past Issues

Four Phases of the Engineering Design Process in Math and Science Classrooms

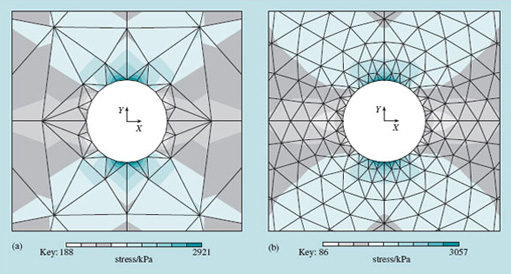

Through a rich and often boisterous discussion, four teachers collectively broke down the engineering design process into four main phases: problem definition, design exploration, design optimization, and design communication.

INTRODUCTION

The KSTF Engineering Task Force¹ (ETF) has been examining how to integrate engineering projects and processes into math and science classrooms. It draws on Teaching and Senior Fellows’ classroom experience. The Senior Fellows that make up the ETF are life science teachers, physical science teachers, math teachers, and even engineering teachers. Some of us are novices whose boundless enthusiasm makes up for our lack of engineering experience; others bring expertise based upon engineering degrees and years of experience in the field.

At the initial meeting of the ETF in summer 2013, we considered the initial question: “What is important in engineering design?” Through a rich and often boisterous discussion, we collectively broke down the engineering design process into four main phases: problem definition, design exploration, design optimization, and design communication.

The ETF’s first three phases align well with the three-phase process outlined in the Next Generation Science Standards (NGSS), with an additional phase to emphasize design communication. We have chosen to represent each phase with a circle instead of an arrow because the engineering process is iterative, not linear. Imagine that each circle is a gear that helps turn all of the others in an effort to complete the whole process. In the first two phases, the engineering process is divergent, where the engineer/student is expanding the design space through brainstorming and creativity. The latter two phases focus on narrowing down the choices, converging to a single, optimized solution.

Each phase offers different rewards and challenges for students, teachers, and engineers, and each phase is critical within the larger process of moving from problem to solution. In the article below, four members of the ETF have each selected one phase, crafting an argument for why we feel that phase is so critical to the engineering design process. We hope that this article will help you understand the engineering design process, provide an impetus for you to incorporate engineering into your classroom, and consider which phase you think is most crucial to the process.

ENGINEERING DESIGN PROCESS DEVELOPED BY KSTF ENGINEERING TASK FORCE

PHASE 1: PROBLEM DEFINITION BY CASEY O’HARA

It is often said that a scientist is not one who gives the right answers, but instead asks the right questions. It might as easily be said that an engineer is one who identifies the right problems. A vague notion of a problem, expertly framed, becomes a worthwhile engineering task. Clever framing can focus attention on one aspect of a grand issue, or can “embiggen” an otherwise trivial problem. In establishing the scope, constraints, and criteria of an engineering problem, problem definition becomes the single most influential phase in the design process.

Let’s examine a broad, challenging problem: cooking practices in rural communities in developing countries are often terribly inefficient in fuel use, create dangerous indoor air pollution, and contribute to carbon emissions. For this example, I will put myself into the shoes of a student, given only the broad problem statement above as my guidance. First, let’s narrow the scope to focus only on cooking practices in rural Kenya. I could have selected a different country, with different practices and needs, or defined an inclusive scope that addresses concerns across many contexts; different choices in scope would likely result in different products at the end of the process.

Let’s establish some constraints, consistent with the chosen scope. With a little research I found that rural Kenyans rely almost exclusively on wood as cooking fuel; I will constrain my design to use wood as fuel, to accommodate existing cultural norms. I might set constraints in price and materials, ensuring that my design is affordable for the average Kenyan family. Again, I could choose different constraints, understanding that this would certainly impact the final design.

It is often said that a scientist is not one who gives the right answers, but instead asks the right questions. It might as easily be said that an engineer is one who identifies the right problems.

Finally, I must determine criteria by which I would evaluate my design. I would like to increase fuel efficiency, reducing both fuel costs and carbon emissions. I would also like to improve indoor air quality and minimize cost. How I choose to prioritize these criteria drives choices involving tradeoffs. For example, adding a chimney to vent exhaust gases might greatly improve indoor air quality, with less improvement to the stove’s cooking efficiency, and likely at a higher price. Which design is preferable? It depends entirely on my priorities established in this phase.

The final outcome of any engineering design project depends on choices made in each phase of the process. But this initial phase—problem definition— establishes the framework within which all other engineering decisions must be made and evaluated. And this extends far beyond engineering—as students develop skills in critically examining problems and defending rational decisions about priorities, they develop a conceptual toolbox to approach problems in any science or math class, as in life.

As teachers, it can be a little daunting to relax our grip on our curriculum, to give our students the freedom to push the bounds of an in-class project perhaps beyond our own comfort levels. But the student engagement and empowerment that results is certainly worth the effort. We want our students to ask the right questions and to identify the right problems—that’s where the engineering starts.

PHASE 2: DESIGN EXPLORATION BY KATHERINE SHIREY

Students work on a newspaper support structure challenge to learn about the four phases of engineering. (Photo by Katey Shirey)

The second phase of the engineering design cycle is the most important in high school engineering: design exploration. It is here that the studentengineer develops a potential solution and where the direction of the classroom is steered away from the teacher and towards the student. In phase two a student-engineer takes a problem statement with constraints and begins to make her investigation into what would best solve the problem. She generates and compares design alternatives through systematic modeling, testing and comparison. At the end of phase two she has a preliminary design that approaches or meets the list of required functions, criteria and constraints from phase one.

Significantly, phase two allows solutions to diverge widely and encompass student interests and curiosities without restriction. It reorients the classroom away from teacher-directed instruction and sends students into a hunt for the best solution. In this way the design exploration phase is the most open-ended and student-centered portion of the engineering design process. Phase two represents a significant divergence from typical models of science instruction where instruction starts with a teacher sharing information with students through lecture, and then students familiarizing themselves with the information by conducting a lab or solving sample problems before being graded on their retention.

In design exploration, however, a student-engineer is encouraged to brainstorm a flurry of design ideas, gather data multiple times on any number of questions that will help to evaluate the ideas, and use other tools, such as a Pugh Chart or decision matrix, to evaluate the designs. There is no predetermined answer to be verified, only limitless imagination to be explored and compared. As they test ideas, students will investigate physical and mathematical constraints—the subject content that a teacher may wish them to “cover” in a more traditional lab.

Last summer I asked 26 high school students at a science and math enrichment summer camp to design a doghouse that would stay warm in the winter and cool in the summer. Students brainstormed, debated, and defended their ideas for the best materials: shingles, wood, foam, aluminum foil, carpet, plastic sheeting, mirrors, tubes, vent panels, solar panels, fans, ice and more. In small groups, students built mock-ups to compare various ideas before deciding on the most important, appealing, and successful designs to carry forward into the next phase. One group decided to pursue a balloon cooling mechanism to blow air into the house; another group proposed a vaulted, open-air second story for the dog to retreat to on hot days.

Without limits or bounds for design, the students worked with deep complexity and interest, all the while developing a better understanding of science content. For instance, they learned how a “biology word” like homeostasis relates to insulation, heat transfer, homes, and energy.

In summary, the design exploration phase of engineering design shifts the purpose of classroom activities away from that of teacher demand and approval, and toward student interest and student evaluation, increasing the intrinsic motivation that students have towards their work.

PHASE 3: DESIGN OPTIMIZATION BY SCOTT MURPHY

Humans have been trying to solve problems since the inception of human existence. Common sentence starters include, “I wish that …” or “Hey, I’ve got a great idea…” The first allows people to identify a problem or a need; the second allows people to explore a design. However, the science of engineering reaches a crucial maximum when we start optimizing our design.

For instance, travel across a long distance has improved tremendously, allowing people to meet, share ideas, and explore new terrain. Think about the automobile; the structure of the car remains largely the same as Henry Ford’s Model T. However, that has not stopped car manufacturers from employing legions of engineers. The problem remains defined (how do we get from Point A to Point B?) and the essential design is very similar. That leaves the process of optimizing the design, given changing priorities.

Companies establish their criteria and priorities in the first phase of the process. They want cars to be affordable, meet certain mileage standards, and be fun to drive. The car must be comfortable; the car must be safe; the list continues. However, until a prototype is actually built, this wish list is simply that—a wish! Engineers are continually collecting data and using that data to make informed decisions about what solutions will yield the best end product. In the classroom, this might look like students building a gravity car based on a set of constraints (e.g., needs to travel a certain distance, stop, complete the trip intact), making a high level engineering project accessible for all students.

After the criteria and constraints are established, the metaphorical rubber of engineering practices meets the road of reality. Everyone would love to build a cheap car that is safe, fuel efficient, and fun to drive. When others would use their gut instinct and hope for the best, the engineer uses data to make decisions. Each time new data becomes available, the engineer returns to the design to improve it. As science continues to discover new ideas and possibilities, the engineers continue to reevaluate their decisions to create the best possible solution. This iterative process separates engineering from other approaches, allowing for the best possible outcome given a set of circumstances. This is an opportunity for students to engage in authentic science dialogue in the classroom. As students collect data on individual variables, they will need to share their information with their classmates in order to determine the most effective design.

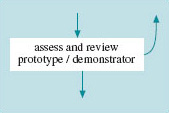

Once a decision has been made, it is time to build and test the concept. Without an actual prototype to test, all of the work is theoretical. This stage is where the engineer confirms the viability of the solution. Often there is a good deal of fine tuning that needs to take place after the construction of the prototype that was not anticipated in the earlier stages. For example, musical instruments are constructed with tuning capabilities to account for small deviations that occur in the physical reality, but not in the abstract theory.

I use this process in my classroom when I give my students the task of constructing their own musical instruments. As students learn about sound and waves, these physical concepts are quite abstract and difficult for them to internalize. By affording students the opportunity to hear the different notes based on changing the design characteristics, constructing a prototype allows students to see how engineering is a relevant skill that they can apply outside the classroom.

This kinesthetic learning helps make science, math, and engineering accessible to students with many different learning styles as they get to actually see their ideas come to fruition. Without the third phase in the engineering cycle, engineers would simply be the philosophers of the science world.

PHASE 4: DESIGN COMMUNICATION BY KELSEY JOHNSON

The fourth phase of the engineering design process provides the most leverage for engineering’s power and utility. Communication is the alpha and omega of engineering; it provides both the invitation and the legacy. Rather than terminating a linear process, communication acts as a revolving door from one design cycle to the next. Our collective body of knowledge, our human inheritance, has grown since people first identified problems or designed and optimized solutions.

The design exploration phase of engineering design shifts the purpose of classroom activities away from that of teacher demand and approval, and toward student interest and student evaluation, increasing the intrinsic motivation that students have towards their work.

Poet Charles Bukowski writes, “genius might be the ability to say a profound thing in a simple way.” Similarly, communication in engineering is not about rhetoric, popular oratory, or winning more followers. Instead, it’s about sharing information so that people, possibly distant in space and time, can use that information to advance the wheel rather than reinvent it. Effective technical communication requires concise, compelling argumentation. Digital media now enable students to engage in this human conversation with unprecedented access and voice. Students showcase their achievements and learn from one another when schools prioritize design communication. For example, schools like the New Tech Network and High Tech High integrate design communication into their academic calendar by utilizing student exhibitions as both a deadline for student accountability and airtime for student voice and growth. A light of motivation ignites in students when they hear calls to solve real engineering problems and have enough scaffolding to engage in all four phases of the engineering design process. Similarly, national calls by organizations like the BentProp Project, First Robotics, and Progressive Automotive X Prize invite high school students to participate in solving real-world problems and to communicate their designs in authentic, inspiring competitions.

Access to information and physical resources are arguably the rate-limiting steps in solving technological problems. As technology enhances the speed that resources can travel over great distances, it also improves the speed with which information can be shared. Communicating evidence-based, logical arguments about what makes a design optimum, what’s been tested and rejected and why, students, scientists and engineers add to our legacy of knowledge at a groundbreaking rate. As our world gets flatter, the fourth stage of the engineering design process provides the guiding light to a better future.

Members of the KSTF ETF consider engineering a vehicle to engage students through creative, authentic problem solving. In presenting each phase of the design process separately, our aim was to create an evidence-based argument for the value of the engineering design process as a whole. We hope that this article has helped clarify the different phases of the engineering design cycle and why each is important for our students.

The ETF’s vision is that all students will get to experience a comprehensive engineering design project in their science or math class, from problem definition through design communication, and that every teacher will have the confidence and resources to provide this opportunity for their students. But we recognize that it might be overwhelming to involve all four cycles of the design process during your first attempt at employing an engineering project in your classroom. It is often easier, for both teachers and students, to start with a lesson that teaches one or two design phases before working up to a full-blown engineering project. We encourage you to start small and modify a pre-existing lesson and experiment to see what happens.

FOR MORE INFORMATION

If you are interested in more information please reach out to any of the authors or Dina Portnoy, KSTF’s Director, Senior Fellows Program (dina. [email protected]). Additionally, more information on how to incorporate engineering in the classroom can be found at the KSTF ETF Resource Center: http://ow.ly/KysPJ . We are very interested in supporting and/or collaborating with other teachers who would like to incorporate engineering into their classrooms. Happy building, happy designing, happy learning!

¹The Knowles Science Teaching Foundation (now the Knowles Teacher Initiative) Engineering Task Force operated from 2012–2016. Since 2017, engineering courses and services have been offered through the Knowles Academy. Visit www.knowlesteachers.org/knowles-academy to learn more.

Download Article

Kelsey Johnson Rasmussen is a Knowles Senior Fellow who teaches computer science and engineering at Erie High School in Erie, Colo. Previously, she taught science in the Philadelphia School District for five years, including the founding year of a project-based school that used engineering design as part of its curriculum. Kelsey was a member of the KSTF Engineering Task Force and the Planning Committee for KSTF Project ASCENT (Achieving STEM Course Effectiveness Through Networked Teachers). Kelsey can be reached at [email protected] .

Katherine Shirey is a Knowles Senior Fellow. She works at the Knowles Teacher Initiative as a Knowles Academy Program Officer. For five years, she taught physics at Washington-Lee High School in Arlington, Va. During that time, she participated as a teacher liaison to the IceCube Neutrino Observatory at the South Pole. In 2017, she earned a Ph.D. in science education from the University of Maryland. Her current research interests are related to the ways that creativity relates to learning in physics instruction. She was a member of the KSTF Engineering Task Force. Katey can be reached at [email protected] .

Scott Murphy is a Knowles Senior Fellow who teaches physics and engineering at St. Joseph’s Preparatory School in Philadelphia, Penn. After starting to use engineering design in his classroom, he proposed that his school have a special engineering class that he designed and is teaching for the fourth time during the 2018–2019 school year. He was a member of the KSTF Engineering Task Force and is the Academy Coordinator for the Knowles Coaching Network. Scott can be reached at scott. [email protected] .

Casey O’Hara is a Knowles Senior Fellow. For eight years, he taught physics, integrated science, and engineering & green technology at Carlmont High School in Belmont, Calif. In 2014, he completed a Master of Environmental Science and Management at University of California, Santa Barbara’s Bren School and an American Association for the Advancement of Science (AAAS) Mass Media Science & Engineering Fellowship at The Oregonian, in Portland, Ore. Currently, he is pursuing a Ph.D. researching the role of social and economic equity in marine conservation. Casey was a member of the KSTF Engineering Task Force. Casey can be reached at [email protected] .

- Engineering Design Process

References and Citation

High Tech High: http://ow.ly/KyFMW

New Tech Network: http://ow.ly/KyFOI

Johnson, K., Murphy, S., O’Hara, C., & Shirey, K. (2015). Four phases of the engineering design process in math and science classrooms. Kaleidoscope: Educator Voices and Perspectives , 1 (2), pages 19-24.

Kaleidoscope Comments?

- Your Name First Last

- Your Email *

What's On Your Mind

- Questions, Comments, or Thoughts

- I consent to my submitted data being collected and stored

- Phone This field is for validation purposes and should be left unchanged.

In This Issue

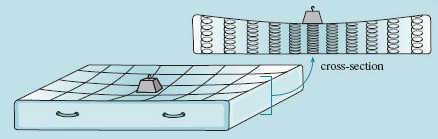

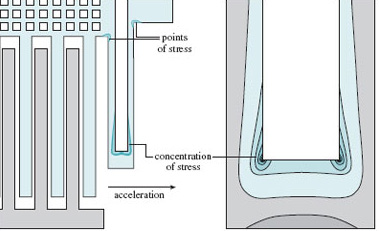

Engineering: The nature of problems

Introduction

The optimistic approach to a problem is to view it as a challenge and an opportunity – a chance to make progress. In this course, the nature of problems is explored by looking at the way they are used as a stimulus for finding solutions. It is presumed from the start that you want to be involved in the process of finding solutions and that you are not expecting simply to be given the answers.

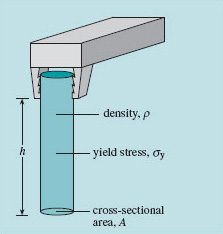

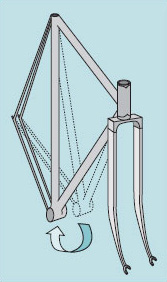

One example that is investigated in this course concerns how to devise lighter bicycle frames, and the way to assess the merits of alternative materials from which to make them. There is no single way to move from a problem like this to possible solutions. In fact there are often several ways to set about finding several solutions, but there are a few general factors that are important to the search.

First it is important to appreciate the needs from which a problem arises. For the bicycle frame it's not just a lighter material that is required, but rather it is one that can be deployed to bear specific loads imposed on a fully functional frame.

Next it is valuable to understand the challenge well enough to be able to specify the nature of solutions, perhaps using the formal languages of engineering, mathematics, science and problem solving. For example, it is unwise to take part in a discussion on 'the best materials for bike frames' without a technical appreciation of both the job a frame has to do and the relevant attributes of the candidate materials. Establishing what you don't yet know usually starts by recognising how effectively you can tell someone else where the challenges arise. You must be able to communicate with a wide range of people, sometimes 'calling a spade a spade', and at other times describing precisely what the word 'spade' actually means.

In passing from a problem towards possible solutions it is essential to be able to evaluate and quantify the technical aspects. Another general factor in the search for solutions is the use of algebra and numbers to compare options and to inform choices. Some calculations are simple evaluations that can be done directly with or without an electronic calculator. Others need a line or two of algebraic analysis. Yet others are too tedious or too complicated to tackle without a computer-based approach using spreadsheets or more sophisticated software.

In the end, the best motivation for learning comes from simply requiring the knowledge in order to make progress.

This OpenLearn course provides a sample of level 2 study in Engineering .

Learning outcomes

After studying this course, you should be able to:

view solutions as belonging to particular categories, broadly classified as: innovation by context; innovation by practice; routine

see how external factors affect engineering projects, and appreciate the range of engineering involved in meeting the basic needs of our society

recognise and apply a range of problem-solving techniques from each stage of the engineering design cycle, to include the following: physical modelling; mathematical modelling; iteration; use of reference data; refining an engineering specification

identify when models are likely to be useful and when they are no longer valid

recognise and distinguish between the following technical terms: differential equation; simultaneous equation; boundary condition; constraint; finite element analysis (FEA); mathematical model; physical model; prototype; demonstrator; anthropometric; ergonomic; product specification; functional specification.

1 Problems and innovation

1.1 solving problems.

It could be said that our species is defined by its irresistible urge to solve problems – it's what makes us human. Strange, then, that the word 'problem' has such negative overtones. I think that the root of this paradox is that the word is used both when we identify a need – the first link in the problem-solving chain – and when we undertake the process of meeting that need. It is the identification of the need and the realisation that it is real and must be met that creates the anxiety and the negative feelings ('Houston, we have a problem …'). The process of finding a solution is the exhilarating part that makes us thirst for more.

I think of my love of skiing. Sometimes I get to the top of a mountain and look down at the precipitous slope I must now descend to get back to safety and a good hot meal, and I am gripped by fear, perhaps even to the extent of wondering whether I'll survive this time. What provides the pleasure, apart from the thrill of speed, is using my skill (such as it is) to meet my need to be safe again.

'The Engineer: Skier on the Technological Piste' is perhaps too bizarre a title for a course, so welcome instead to T207_1 The engineer as a problem-solver: the nature of problems .

T207_1 is taken from an Open University course entitled ' The Engineer as Problem Solver '. The fact that we have prepared a course with this title shows that we think there is something useful to say about the process of solving engineering problems. It seems to imply that there is a technique to be learned – a preferred method. To a degree, this is true; experience has taught us that there are certain ways of proceeding which tend to lead to better solutions than others. This course is designed to give you a flovour of the skills and knowledge that will help you to make active and informed decisions when tackling your own engineering problems.

In engineering, solutions to problems come in three categories:

innovation by context;

innovation by development;

This is going to need some explanation, so here goes.

The categories differ from one another in the extent to which the solution is a step into the unknown, and this is why it may be chosen before the solution itself is known.

| Old technology | New technology | |

|---|---|---|

| New context | innovation | invention |

| Old context | routine solution | innovation |

As you can see, there are four sectors in the table, defined by the technological newness of the solution, and the newness of the context in which it is to be applied.

The 'customer' for the solution will often have a very definite idea of the sector in which they wish the engineer to operate. For example, a new heart pacemaker will be heavily constrained in many respects: only certain materials will have been approved for the casing, as they have to be biocompatible; certain safety features must be included, such as methods of making sure the casing is hermetically sealed, making the device immune to electromagnetic interference, limiting the power and frequency of the heart stimulation; as well as other limits such as on the minimum lifetime of the battery and the need to provide sufficient warning of its decline to allow it to be replaced in time. The list is much longer than this. The effect is to discourage excessive innovation (by which I mean a significant change to the way something is made or the way it works – or a new type of thing entirely) and the chances are that an innovation by development will be the order of the day.

We define innovation by development as changing the bit that doesn't work, or that could work better, to improve the function of the whole product or design for reasons of cost, performance, ease of manufacture or gaining competitive edge.

This tight constraining of innovation does not preclude entirely the invention of a new type of pacemaker, but it is unlikely that a manufacturer will be asking its engineers to throw away the rule book and dream up something new. If an innovative pacemaker is to appear, it will be because someone has had a sudden inspiration, and the idea is so very good and the potential benefits so great that a manufacturer is prepared to take a large risk and go through years of testing to gain safety approval.

It is usually where safety is a critical factor that we find a tendency to reduce the amount of innovation, so it would be equally easy to find an example from the oil industry, or from the aerospace or military fields. Very conservative purchasers are the other main reason for holding back on innovation. Perhaps surprisingly, the industrial process control market is one such area. Engineers responsible for the design and installation of processing plant usually take a lot of persuading that a new type of flowmeter, say, will be better than the one they know and have been using for many years.

At the other extreme, there are just as many examples where innovation is essential to the success of a project. There's even a well-known mail-order catalogue whose very name includes the word. The market for gadgets and gizmos is huge, and rather prone to the vagaries of fashion. These two characteristics make it a powerful driver for innovation. Last year's temperature-indicating tea cosy with built-in radio, flashlight and satellite navigation system may have sold a million, but it's a little passé now ( Figure 1 ).

Another important instance where we know in advance that an innovation is required is where the existing technology is very mature, and has been incrementally developed as far as it is possible to take it, yet we have identified a need to improve the performance of the product still further. In this case, we can clearly see that innovation will be the only way to get there. An example of this is the bubble-jet printer. In the late 1970s and early 1980s, the vast consumer and small-business market for printers could not stand the cost of laser printers, yet was demanding better quality, less noise and higher speed from the alternative, which was the dot-matrix printer. This works by transferring ink from a typewriter ribbon onto the paper, using an array of electromagnetically actuated pins. These had been improved over many years, and were about as good as they could get. They had reached the limits of how fine a pitch they could be arranged on at a reasonable price but, even so, they were still rather slow and noisy.

What was required was an innovation, and this came in the form of the bubble-jet, which was an entirely new technology based on the ability to etch arrays of very fine holes in a polymer substrate using photolithography. The ink is transferred to the paper by creating pressure pulses behind the appropriate hole, using electrical heating. A single drop of ink is then ejected at high speed and strikes the paper. At a stroke, the new technology provided marked improvements on speed, pitch and noise level, and all without increasing the cost of the product.

1.2 Innovation by context

The word 'innovate' simply means 'make new'. We have chosen in this course to narrow the meaning of this term to be more or less synonymous with 'invention'. I would argue that innovation by context is as much a process as a result. By that, I'm using the term to mean something more like 'creativity'; and it's creativity that lies at the heart of all engineering. More than anything else in our professional lives, we engineers are excited by the prospect of being responsible for the creation of something better than we had before. This does not mean that all engineers are inventors in the sense that the word is normally understood (i.e. taking out patents on some new gadget). Innovation by context is the fruit of the creative process going on in the mind of the engineer when solving a problem, and can be anything from a clever change in the design of a computer program that allows it to run faster or use less memory, to something revolutionary like the jet engine.

For an engineer, creativity is a daily activity. Sometimes, the result is a big enough innovation to call an invention, and to patent, but mostly it's just small but necessary steps in reaching the goal. You can be creative even if your solution is of the type we classify as routine, as we'll show later. There are numerous great examples of innovative solutions, some of which are inventions. How about the first aqueduct, canal, drain, concrete, pilotless aircraft, the building of the Eden Project in Cornwall, the new roof over the British Museum, radar (mapping the skies, speed cameras and predicting weather), the first mobile phone, waterproof fabric, the microwave oven, the compact disk, Dyson's bag-less vacuum cleaner? … the list goes on. It's difficult to pick one example for looking at in more depth, but one of the best and most simple examples of innovation by context has been the transformation of radio into a self-sufficient technology, described in Box 1 .

Box 1 Innovation by context – an example

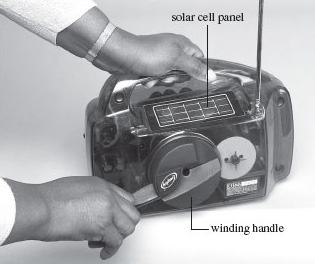

In 1991, inventor Trevor Baylis saw a television programme about AIDS workers in Africa. In poor countries radio broadcasting had always played a part in health education, but in this programme the workers were explaining how batteries were expensive or unavailable and electricity supplies unreliable or simply non-existent. The programme provided Baylis with a problem, and inspired him to find an innovative solution.

Baylis's invention, as you have probably guessed, was the clockwork radio, Figure 2 . He wasn't the first person to use springs to generate electricity, but prior to his design the energy had only ever been produced this way for short bursts at a time – here is the context . The innovation is in applying springs to the provision of low-power electricity for consumer electronics. Baylis invented a mechanism that gave forty minutes of play from just twenty seconds of winding. The winding action coils a spring, attached to a gearbox, which is connected to a dynamo. When the spring is released the gearbox controls the steady discharge of energy to produce electricity, and the radio works. The dynamo provides three volts at between 55 and 60 milliwatts, but the design also incorporates a solar-powered source to extend its performance.

Thus power is generated from human input, backed up by free and widely available solar power. Baylis realised that his new technology had huge potential. However, this was only half the task: he also needed to reduce the amount of power consumed by the radio, and this is where the less glamorous and less visible (but at least as important) part of the innovation was done. A team of electrical engineers worked to make improvements in small increments until the power consumption was pared down enough to allow the radio to work for a reasonable amount of time between rewindings of the spring.

Reaction to the radio was initially somewhat sceptical but eventually, in 1994, a prime-time BBC TV programme ( Tomorrow's World ) agreed to feature the idea. Two entrepreneurs who happened to be watching contacted Baylis immediately, going on to form a company with the intention of putting the clockwork radio into production. 'Freeplay', as they were called, raised a government grant for initial development costs and then found investors, to date selling over three million units. The company has the endorsement of heads of state, international aid organisations, royalty, celebrities, the European Union, the United Nations and more, and has gone on to develop other similar products.

The original problem – that of providing a self-sufficient technology so that radios could be widely available in developing countries – has been solved not only in theory but also in practice, the true test of an innovation.

1.3 Innovation by development

Innovation by development is about changing the bit that doesn't work, or that could work better, to improve the function of the whole for reasons of cost, performance, ease of manufacture or competitive edge. You probably noticed in Box 1 'Innovation by context – an example' that Baylis had to incorporate a number of developmental innovations as well. Improvements in materials or production equipment or techniques can present solutions to manufacturing difficulties, and so development becomes incremental not only in a product, but in a chain of production.

It's where the big money lies for companies wanting to keep one step ahead of their competitors without the (in general) higher risks and longer timescales of innovation – 'our powder washes brighter', 'this battery lasts longer' or 'this car is quieter to drive'.

Most technological items in everyday use have been subject to innovation by development. You can see the results in the motor industry, in aeroplanes, trains, mobile phones, computers, fridges, cookers, plastics, household implements … it's more difficult to think of something that hasn't been subject to innovation by development! Box 2 Innovation by development – an example explores a typical product development.

Box 2 Innovation by development – an example

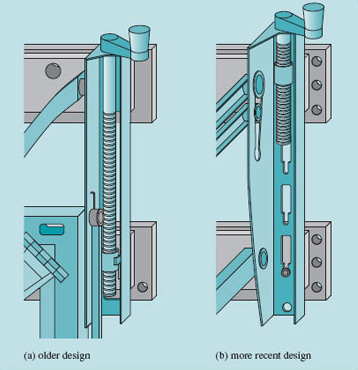

The Black & Decker Workmate portable workbench ( Figure 3 ) has been the DIY and professional craftsman's best friend for thirty years now. At first sight, it is a product that has not changed much at all in that time; but if you look more closely, you will see that it has undergone a considerable amount of innovation by development. However, this has been done over such a long period of time that you need to put the original next to a new one to spot the differences. We can look at some of these changes and try to guess why they were made.

The original Workmate had a pair of long leadscrews ( Figure 4a ), one on each side, to move the jaws of the vice-cum-work surface. The length of these screws was over 30 cm, and they moved the half of the table furthest from the user relative to the other half, which was static. This enabled the bench to offer one of its best selling points: the ability of the vice to accept a large range of workpieces, including wedge-shaped and very wide ones.

The current design has switched things around, so that it is now the part of the top nearest the user that moves, but the leadscrews are very much shorter and therefore lighter ( Figure 4b ). This would normally restrict the range of widths of workpiece that can be accepted, but this has been restored by making the other part of the top removable. To accept pieces with a width that is outside the range of the leadscrews, this part of the top is simply unlocked from the framework and moved into one of the alternative locations for it, providing a new range of jaw separations that overlap slightly with the previous position.

Make a list of the effects of the change to the design of the Workmate's vice mechanism, noting the beneficial and detrimental effects for each one from the manufacturer's and the user's point of view.

Why do you think this change has been introduced?

Cost saving on leadscrews:

better margin for manufacturer, lower price for user.

Reduction in weight:

reduced distribution cost for manufacturer, easier to carry for user.

Screw does not now pass under the opening of the vice:

no direct effect for manufacturer, reduced likelihood of clogging with sawing debris (and therefore excessive friction) for user.

Extra operation of removing and replacing the moving jaw required for changes in workpiece width that exceed the leadscrew travel:

no direct effect for manufacturer, less convenient for user for small changes in workpiece width that nevertheless require relocation of the moving jaw, though quicker to change jaw separation for large changes in workpiece width.

The effects on both the user and manufacturer of all but the first change are slight. Therefore, the likely reason for the change is the first one – cost saving. This is partly offset by a cost to the manufacturer in making the change – the cost of the design work, changes to drawings, parts lists and order schedules. Note that the cost reduction has a beneficial effect for both the user and the manufacturer.

1.4 Routine solutions

This is the last of our three categories, and possibly the most difficult to define because the approach is not as definite. Routine solutions involve configuration or reconfiguration of existing devices or components, without innovation, because something is broken or needs to be repositioned, or there is simply a better way to do it. If you change the locks in your house or car, you are reconfiguring them; if you tune the car, calibrate the central heating, set the coordinates for your satellite navigation system, change from an overhead lamp to a wall light, or even just change station on your television, you are applying a routine solution to a problem by reconfiguring the bits. As I write, I'm reminded of the ongoing attempt by a group of stalwarts to reconfigure the standard keyboard, originally designed to prevent the letter levers clashing on a manual typewriter, into something more user-friendly for today's computer user.

The biggest examples of challenges requiring routine solutions are, literally, physically big. Things that need configuring are often remote, such as a fibre-optic signal booster in a cable at the bottom of the Atlantic, or, at the other extreme of the planet, a satellite; both of which (as it happens) are critical to intercontinental telecommunication. Box 3 Routine solution – examples looks at some examples.

Box 3 Routine solution – examples

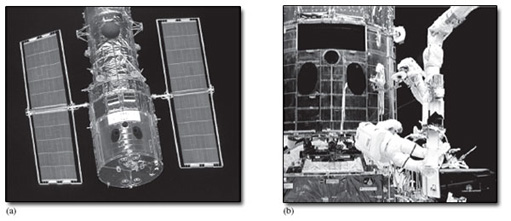

The Hubble space telescope ( Figure 5 ) was conceived in the 1970s. The intention was that it would capture astronomical images, unimpeded by the Earth's atmosphere, and transmit data and images 640 km back to Earth, enabling us to answer some of our most fundamental questions about the universe. It was sent into orbit in April 1990, at a cost of about US$ 2 billion.

However, just weeks into its flight the mission was very nearly lost before it had truly begun, when NASA scientists discovered that the main concave mirror of the telescope had been ground too flat by a depth of 4 micrometres, resulting in images at high magnification that were too fuzzy to be useful.

The operators who control Hubble's flight work in team rotation, driving it 24 hours a day every day of the year, sending an average of over 100 000 instructions a week. The first opportunity to carry out maintenance, install new instruments and correct the error (by giving it 'glasses' in the shape of five pairs of corrective mirrors) came in December 1993, after two years of planning. Engineers operating the telescope trained extensively for the reconfiguration of Hubble. First the telescope had to be set aside from its usual research operations to a 'ready for servicing' condition and capture attitude, then the aperture door was closed and high-gain antennas stowed. Astronauts on board a Space Shuttle made five gruelling space-walks to carry out the installation work. Once this was completed and tested, both Hubble and the Shuttle were configured for battery charging. When charged, everything on the telescope was reactivated and it was released back into orbit. To everyone's very great relief the mission was a success, and Hubble soon began transmitting the great pictures that had been anticipated.

Why do we describe this as 'routine'? Clearly the solution being sought was not expected to be innovative – the commitment to reflective optics was unchangeable. Similarly, the cost of a series of incremental improvements would be prohibitive. What was called for, and what was done, was routine reconfiguration of the bits.

A less glamorous example is found in electronic circuit design. New amplifiers, data acquisition cards and so on are launched every year.

Many are new arrangements of standard components – resistors, capacitors, integrated circuits, etc. The problem solving here has been concerned with choosing component values and characteristics to achieve enhanced performance.

You should, by now, have a better idea of how to classify solutions to problems, challenges and opportunities. The three groups above overlap. It's possible for a solution to be equally valid in more than one group at a time. It's important to consider the context of whatever you're facing – the invention of the mobile phone was an innovation in terms of electronics, subsequent innovation by development has been largely incremental, and during this development there have been considerable routine design changes. If you're deciding where the solution to a problem belongs, try to narrow it down to its basic elements.

Group the following tasks as being problems likely to find solutions that are routine in nature, that involve innovation by development or require innovation by context :

Making a lighter ladder

Specifying components for a home-computing workstation

Defining specifications for building services in a new factory, e.g. ambient temperatures in different rooms/areas, air conditioning, waste air extraction, etc.

Designing a taller crane

Replacing lead-based solders with non-lead alternatives

Bridging a wider gap

Setting network and modem parameters for an office PC system

Designing an ejector seat for a helicopter (ouch!).

Specifying components for a home-computing workstation (selecting from among existing components)

Setting network and modem parameters for an office PC system (selecting from existing options)

Defining specifications for building services in a new factory, e.g. ambient temperatures in different rooms/areas, air conditioning, waste air extraction, etc. (selecting from among existing components)

Innovation by development:

Designing a taller crane (extend a shorter crane)

Making a lighter ladder (refine the design to reduce weight)

Bridging a wider gap (extend an old design)

Replacing lead-based solders (devise new alloys)

Innovation by context:

Designing an ejector seat for a helicopter (ejector seats were conceived for fixed-wing aircraft and can't simply be transferred to the pilot's seat in a helicopter).

2 Where does the need arise?

There is a rather obvious question that has to be raised at some point, so we may as well get it over with now: Why do we present ourselves with all these problems? After all, life would be easier without them and we could all go off and do jobs that don't involve them. Do we really need to know everything about the universe? Or to send people into space, at significant cost and human risk? Do we really need to send sound and pictures through space? Do we really need to communicate with people we've never met? Do we really need to educate people about health?

I hope you have at least agreed with the last one, and you can probably see a connection that runs through the points that were used as evidence in the last section. What it illustrates is an order of priority of human needs, ranging from the immediate and essential, to the remote and desirable, and that engineers are active at every level.

Arrange the following items in order of human physical need, with the most basic requirement at the top:

Communication

Entertainment

This is only my list, and your own personality will probably dictate how you placed the bottom six. The point is that we can survive no more than a few minutes without oxygen, a day or two without water, and a week or two without food. In extreme environments we can't survive without shelter and/or warmth. As for the rest: well, on this particular scale they can be seen as life's luxuries, although in relatively rich societies we are expecting more and more as our right rather than privilege. Engineers are involved in meeting all these needs at every level and at every depth of complexity.

However you organised the above list, you can see that there is a hierarchy of human requirement where the needs become increasingly refined and complex, and that there are problems, challenges and opportunities for the engineer at every level. All the items in the list could be expanded to consider the engineering involved. Box 4 Meeting the liquid challenge looks at how we meet the fundamental need for a supply of clean water.

Box 4 Meeting the liquid challenges

To all practical intents and purposes, water on Earth is part of a closed system – there is no more or less water on the Earth's surface now than when the first humans were alive. It is approximately 1400 million cubic kilometres of the ultimate recyclable resource, and it is random in its availability. We use it to drink, cook, wash and flush sewers, and without it any one of us would die within a week. Apart from the very air we breathe, it has to be our most basic need.

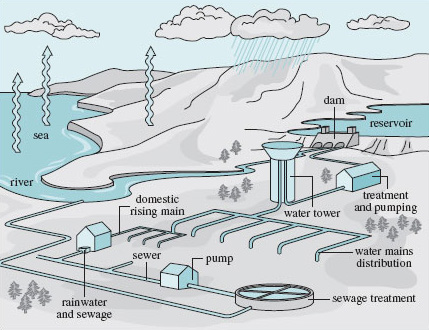

In temperate zones in the northern hemisphere, we are lucky enough to get a reliable amount of rainfall, which we can store in artificial reservoirs. Water has to be collected from lakes and reservoirs, wells, rivers and underground pools, then treated and transported for domestic and commercial use on a mammoth scale (Figure 6).

Think about the engineering involved in designing, building and lining reservoirs; designing and laying pipes of the right material and capacity; controlling water flow through the pipes; filtration and purification; delivery to domestic and business premises; removing, storing and treating sewage; managing the logistics of supply and demand; and the financial and technical administration of the water system. We may have cause to grumble about the occasional shortage in supply during long dry summers, but our system is generally robust. Generations of engineers have been responsible for the development of reliable water provision around the world (though there are still places where the challenges remain). If you have ever visited a country where you had to rely on sterilised or boiled water, you will appreciate it all the more.

In many poor countries the history of problems caused by drought or contaminated water is well documented. It is currently estimated that 2.4 billion people worldwide lack access to basic sanitation, and over a billion are drinking unsafe water. The engineering challenges posed in these countries (mainly in Eastern and Southern Africa, and South Asia) are different from those met in most of Europe as the rainfall is less reliable, work is often funded by overstretched charities and, although a long-term infrastructure is needed, there is also an urgent necessity to provide instant clean water. Engineers are working on a small, local scale, sometimes having to show innovation with the materials and resources available and meet needs by practicality at the expense of efficiency. They might have to find water below ground, or find a means of purifying water from a river. Engineers may also find themselves becoming educators – passing on their skills and advice to local communities who can then carry out work for themselves.

Internationally, as in any industry, there are groups of engineers and scientists committed to research and development at the boundaries of our existing knowledge. The most recent high-profile discoveries in the water industry are to do with the desalination of sea water, a huge and largely untapped aqueous resource.

Many sectors of engineering are involved in meeting such a basic need as the supply of fresh water. The three classifications of solution – innovation by context, innovation by development and routine – are all represented many times over, and there are numerous angles of opportunity and challenge. If you consider a similar breakdown for each of the needs you listed in Exercise 2 , you begin to get some idea of how and where engineering solutions are required. Here's a summary for this case:

designing, building and lining reservoirs;

designing and laying pipes of the right material and capacity;

controlling water flow through the pipes;

filtration and purification;

delivery to domestic and business premises;

removing, storing and treating sewage;

managing the logistics of supply and demand;

the financial and technical administration of the water system.

3 Needs and problems

The last section has established that engineering is about satisfying needs. In fact, with so many needs, it's a wonder that not everyone is an engineer! So, now that we have talked about both needs and problems, the logical progression is to examine the relationship between them.

Take the water example as being a fundamental need. We can state it thus:

This village needs a supply of clean water.

When given that statement, we have a natural tendency immediately to start looking for potential solutions – a trough for rainwater, purification for river water, a pump for underground water and so on. We will start asking questions to get a clearer definition of the need – What's the average rainfall? Is the village near a river? Do we know of any existing supplies? What physical resources are available? How much water is needed daily – is ten litres each enough? What do we mean by 'clean'? etc. Seamlessly, the need becomes a problem that requires a solution. The definition of requirements makes it precise.

The problem becomes how to transfer and purify sufficient water from a source, say a river, half a kilometre away.

With this amount of detail we have a problem definition, and all that's left is to find a solution …

(a) State, in a few words, the need which prompted the development of the Baylis wind-up radio.

(b) Make a list of bullet points that identify the engineering requirements involved in meeting the need for communication, like the list at the end of Box 4 'Meeting the liquid challenge' .

(a) The need for reliable, affordable access to broadcast health information in remote areas.

(b) adequate radio reception equipment

adequate power provision (clockwork and solar)

adequate manufacture and assembly

shipping and distribution

robust business plan.

4 Looking for solutions

4.1 advancing knowledge.

Over the centuries, engineers have faced and solved a huge number of problems of one sort or another. Each time a problem is solved, knowledge is advanced, something usually gets written down, and so today we have a wealth of experience to draw on. Equally, problem-solving techniques have also been developed and evolved through use and refinement, which is rather handy. Not only do we have some idea of existing solutions to similar problems, but we also have an indication of how to go about finding our own solutions.

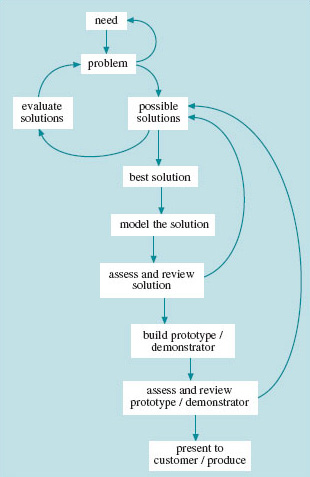

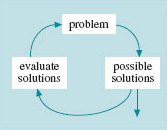

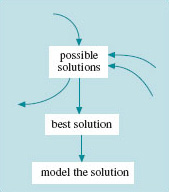

As we're trying to get a picture of the whole, let's begin by looking at a typical, simple, problem-solution process and then we can break it down into separate elements. Figure 7 is one attempt to map out such a process, from the top down.

I should add, however, that there is no single right way to do this and there are, inevitably, all sorts of diagrams available to illustrate the process of creating solutions to problems. Engineering is a huge field, and procedures are usually shown with a bit more detail than in Figure 7 because they are specific to, say, software design, mechanical, chemical, civil engineering, etc.

4.2 From a need to a problem

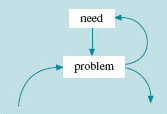

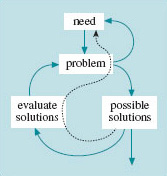

So, working from the top down, the process starts with 'need' and 'problem'; see Figure 8 .

Although we usually work by identifying a need that converts to a problem, that requires a solution, don't forget the extra arrow at the side, taking this first part of the process full circle. The questions that draw out the problem may also refine needs, or indeed extract further needs that were not stated, acknowledged or recognised at the very beginning. We've already looked at where these needs come from on a global scale but, unless you are an academic researcher or a totally independent inventor, by the time you reach this stage of design the need is usually coming very directly from a customer. The customer may be your employer, or an external client, who has somehow identified the need to develop a new product or significantly modify, improve or repair an existing one. It's obvious that the better the specification, the less time and money will be wasted in designing or producing a product or solution that doesn't meet the requirement.

There are different types of specification – for example, a 'product' specification and a 'functional' specification. If the supplier has more knowledge about the specific product than the customer then a functional specification is appropriate. However, if the supplier is just making a design to order then a full product description must be agreed. The writing of these formal documents that attempt to ensure that the solution matches the requirements has become something of an art. The specification may become a legal contract that binds the engineer to the task, instead of a practical guide to the route and therefore the solution to a problem. While nobody would argue that you should not have some sort of guarantee that you're going to get what you are paying for, it does seem to be a shame that the more control is exerted in this way, the less room there will be for creativity and hence innovation in devising solutions. Used properly, the specification can be arrived at by an open exchange of views and ideas between the two (or more) parties involved, so that the engineering team goes away to look for solutions with a clear record and understanding of both the need and the problem. An example of the process that leads to a specification can be seen in Box 5 From problem to specification .

Box 5 From problem to specification

Between the 1930s and 1980s, millions of industrial and domestic refrigerators and freezers were produced which used chlorofluorocarbon (CFC) gases as the refrigerant and in insulating materials. CFC gases didn't degrade the fridge, were non-flammable, not poisonous in the event of a leak, and seemed to be an ideal replacement for the original refrigerants such as ammonia that were smelly, corrosive, poisonous and not particularly efficient. However, it transpired that CFC gases are damaging to the environment, depleting the ozone layer that protects us from the harmful ultraviolet components of the sun's rays. A need was thus identified – for fridges and freezers that are environmentally friendly ( Figure 9 ).

It is worth noting that this statement of needs is not at as fundamental a level as the earlier one in the water example. This illustrates the existence of the hierarchy of need. We need the ability to create cooled environments not only for keeping food fresh, but also for countless industrial processes. We are able to state the need in terms of fridges and freezers because there is a long history of market requirement and product development that moves the starting point of our need statement on from 'we need to keep our food fresh', through 'we need to make things cold' to 'we need fridges and freezers'.

There is a general principle here in the formulation of statements of need: the more fundamental the terms in which it is written, the greater the variety of solutions open for consideration, but the greater the possible number of dead ends. There is therefore a balance to be struck between maximising the chances of a really creative solution, and wasting time considering unsuitable ones. So, the statement 'the village needs a supply of clean water' leaves more options open than 'the village needs a water pump and filtration to get clean water from the river'.

To take this statement of the need the next step forward, we have to write a problem specification, which ideally will contain all the information necessary for working out a set of possible solutions.

Our need was stated as 'environmentally friendly fridges and freezers'. We can further refine this to 'we need alternative refrigerant gases to CFCs'. In doing this, we have excluded the possibility of using an alternative technology to the compression/expansion heat pump that is ubiquitous in refrigerators and freezers. There is a very good reason for this: the closed-cycle mechanical heat pump is the most energy-efficient known means of refrigeration, and to go to something that uses more energy could add an unacceptable environmental cost.

We can now state the requirements for the solution: A refrigerant gas with the following properties:

Not an ozone depleter

Compatible with conventional heat-pump technology

Non-corrosive

Non-hazardous (i.e. non-toxic, non-flammable)