Talk to our experts

1800-120-456-456

- Working Principle of an Electric Fuse

What is an Electric Fuse?

An Electric Fuse is an Electric device which interrupts the flow of current in an Electric circuit. It is installed in a circuit to stop the flow of excessive current. A Fuse is usually a short piece of wire. The Fuse is made up of a material which has high resistivity and low melting point, so that it melts down due to overheating of the wire during high current flow.

The thickness of the Fuse wire is determined based on the amount of current flow in the circuit. Normally an alloy of tin and lead is used as the Fuse wire, as it has high resistivity and low melting point.

If a fault causes a flow of excess Current then a thin Conductor is used to break the Circuit by melting or separating it, the thin Conductor used is known as an Electric Fuse. A Fuse can be sacrificed if anything in the Circuit goes wrong since they are weak points that are intentionally placed in a Circuit. For example, in order to protect the wiring of the vehicles, a Fuse panel is placed near the batteries of the Car.

The wire inside the Fuse melts if there is an occurrence of high Current due to a short Circuit or an overloaded Circuit. As a result of which the Current stops flowing since the wire has broken. In order to stop the flow of Electricity, the Electric Fuse gives up its life. There is a clear plastic window in some Fuses from which one can check if they are still good.

Electric Fuse- Working Principle

The Electric Fuse works on the basis of the heating effect of the Electric Current. It is composed of a non-flammable thin metallic wire with a low melting point.

If a high amount of Electricity is passed from the Electric Fuse, there is a production of heat which causes the Fuse to melt which leads to the opening of the Circuit and the blockage of Current.

Once a Fuse melts, it can be changed or replaced with a new Fuse.

A Fuse is normally made up of elements like zinc, copper, aluminum and silver.

A Fuse acts as a circuit breaker and breaks the circuit in case any fault occurs in the circuit. It acts as a protector of Electric appliances and also as a safety measure for humans. The figure below represents a Fuse operation, Fuse barrel and Fuse link.

Characteristics of an Electric Fuse

Here are some important characteristics of a Fuse wire.

Current Rating: It is defined as the continuous conduction of maximum current holded by the Fuse without melting. It is the capacity of current, and is measured in Amperes. Current (C in )=75% current (rating)

Voltage Rating: If voltage is connected in series with the Fuse, it does not increase voltage rating.

V (Fuse) >V (open circuit)

I 2 t Rating: It is the total energy which is carried by the Fuse element in case of a short circuit. It measures the heat energy of the Fuse, and is generated when the Fuse breaks out.

Interrupting or Breaking Capacity: The maximum rating of current without harming the interruption by the Fuse is known as interrupting capacity of the Fuse.

Breaking capacity > maximum rated voltage

Breaking capacity < short circuit current

Voltage Drop: The Fuse element melts whenever there is an excessive current in the circuit, and opens the circuit. Due to this, voltage drop and resistance change reduces.

Temperature: The Fuse melts when the operating temperature is higher and the current rating is lower.

The graph represents temperature vs current carrying capacity of a Fuse. The current carrying capacity of a Fuse is 100% when the temperature is 25°C (three lines meet at this point). After that the current carrying capacity decreases upto 82% at 65°C. This shows that increase in temperature decreases the current carrying capacity of a Fuse.

Electric Fuses are proven to be helpful in safeguarding any Electrical appliance or household Circuits. Its features are-

The melting points of Electric Fuses are very low, which is 200° C.

Fuse wires are made of an alloy composed of 50% lead and 50% tin.

The resistance of Fuse wires is so high that whenever its temperature rises and it reaches its melting point, it breaks the Current which passes through the Circuit.

Functions of Electric Fuse

Electric Fuses have to give up their lives in order to safeguard the Circuits. Some other important functions of Electric Fuses are listed below-

Restricting the flow of Current- An Electric Fuse acts as a barrier between an Electric circuit and the human body.

Preventing the wires from catching fires or breakdowns- It prevents any damage to the Electric device by restricting excess current flow.

Terminating the Current from the Circuit if a short- Circuit or overloading happens- When too many appliances are connected in a single circuit, it leads to overload which requires a Fuse to terminate the circuit connection.

Prevention from blackouts- if any dis-function occurs in the components of the circuit, the nearest circuit breaks.

Prevention from damage occurred due to mismatched loads.

Information about the ampere rating, voltage rating, approval standards of the Fuse and interrupt rating are generally marked on the Fuse. This information must be checked and verified before buying a Fuse.

FAQs on Working Principle of an Electric Fuse

1. What are the Different Types of Fuses?

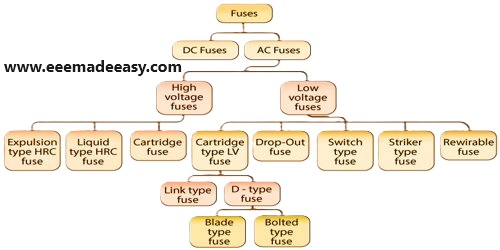

Fuses were invented by Sir “Thomas Alva Edison”. Many Fuse types are available in the market. Mainly the two types of Fuses are :

DC Fuses: DC Fuses are large in size. DC supply has a constant value, slightly above 0V. So, it becomes hard to turn off the circuit, thereby creating a chance for an Electric arc between melted wires. To overcome this, electrodes are placed at a larger distance in the Fuse. For this reason the DC Fuse is bigger in size.

AC Fuses: AC Fuses are generally smaller in size. They oscillate around 50-60 times per second from minimum to maximum. No chance of Arc between the melted wires arises. For this reason the AC Fuse is small in size.

AC Fuses are further categorized into two types, i.e., High voltage Fuse and Low voltage Fuse.

High-voltage Fuse - High voltage Fuses are further classified into three types of Fuses which include a thermal Fuse, cartridge type Fuse, and a high voltage liquid Fuse. Thermal Fuses protect Electrical equipment from damage from overheating. The cartridge-type Fuses are used to prevent the corona effects at high voltage and are used in parallel. High voltage liquid Fuses use carbon tetrachloride from arc extinction.

Low-voltage Fuses- Low-voltage Fuses are also classified further into two types: rewirable and cartridge type. The rewirable Fuses are most commonly used in house wiring. The cartridge Fuses are enclosed in containers that are tightly sealed and have a metal contact at both ends. Cartridge Fuses have two types- Link-type of High Rupturing Capacity Fuse and D-link Fuse.

2. What is the Principle of Fuse?

Electric Fuse is based on the principle of heating effect of Electric current. Heat is produced when current flows in the wire. When heat production is more due to excessive flow of current, it melts the Fuse which normally has a low melting point, thereby preventing any damage to the Electric circuit and appliances.

3. What are the Uses of Fuse?

The Fuses are one of the most important parts of an Electric circuit and an electronic system. Here are some uses of a Fuse:

They are used in home distribution boards, Electronic devices and Electric appliances to prevent any damage due to excess current flow.

They are used in gaming consoles and all automobiles like cars, bikes, scooters, trucks and all other vehicles.

They are used in laptops, printers, cell phones, hard disk drives, scanners, and portable electronics.

Fuses are used in capacitors, power converters, transformers, power transformers, motor starters if an Electrical distribution system.

They are also used in LCD monitors and battery packs to stop excessive current flow to the device and prevent it from damage that may occur to electronics.

4. What are the two main parts of an Electric Fuse?

The two main parts of an Electric Fuse consist of a Fuse element as a metal Conductor attached with a pair of contacts and a cartridge or a case that carries the Fuse element. Cartridges are adjusted with arc-extinguishing devices. If there is a short Circuit then the Current flowing through the Fuse element exceeds the prescribed limits which lead to the creation of excess heat that metals the Fuse wire and breaks the Circuit.

5. What are some advantages and disadvantages of an Electric Fuse?

Some of the advantages of an Electric Fuse include-

Electric Fuses are the cheapest available form of protection.

Minimal operating time.

There is not any need for repairs.

Short-Circuits disrupt without any production of gas or smoke.

They work automatically.

Current protection is due to the inverse-time Current characteristics.

Some of the disadvantages of an Electric Fuse are-

It is not always possible that the Current-time characteristic is always correlated with the protection of the device.

A considerable time is taken after the operation in order to replace the Fuse.

6. What are some differences between a Circuit breaker and a Fuse?

The most primary difference between a Circuit breaker and a Fuse is that once a Fuse is melted, it has to be replaced and it gives up its life while in the case of a Circuit breaker it can be reset and used over. Circuit breakers are devices that stop the Current flow as any fault occurs while a Fuse destructs itself whenever the Current exceeds a certain limit. To learn more about Circuit breaker and Fuse differences, students can visit Vedantu’s study material on the difference between a Circuit breaker and an Electric Fuse.

7. What is meant by the term MCB?

Electromechanical devices that are designed in order to protect an Electric Circuit from over-loaded Currents are known as miniature Circuit breakers or MCBs. The three principle characteristics that and an MCB possesses are- Amperes, Tripping curve, and Kilo-Ampere. Unlike Electric Fuses, MCBs do not self-destruct themselves and are replaceable. It is very easy and safer to use MCBs since they offer a convenient on/off switch and the Conductor is encased within a plastic case making them safer to operate.

- Electricity Today Magazine

- Intelligent Power Today Magazine

- Arc Flash Clothing

Electricity Forum

What Is A Fuse? Protective Device

by R.W. Hurst, Editor

What is a Fuse?

A fuse is an electrical safety device that protects electrical circuits and electronics devices from damage caused by excessive current. It does so by melting and breaking the circuit when the current surpasses the safe limits. Fuses are available in various types and ratings, making choosing the appropriate fuse for the specific application crucial. In addition, proper electrical engineering selection and maintenance of fuses can help prevent electrical fires and ensure the safety and longevity of your electrical systems.

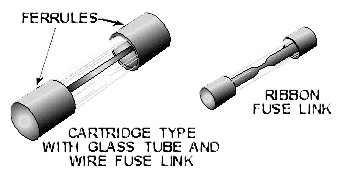

Various fuses are available, each designed for specific applications and environments. Some common fuse types include cartridge fuses, which are cylindrical and used in electrical panels or appliances; automotive fuses, typically found in vehicles' electrical systems; and high voltage fuses, which protect electrical equipment in power transmission and distribution systems.

Fuse ratings are essential when selecting a fuse for a particular application. The rating indicates the maximum current the fuse can safely carry before the fuse blows. Choosing a fuse with a suitable rating for the electrical device or circuit it is meant to protect is crucial. Overrating or underrating a fuse can lead to inadequate protection or nuisance tripping, respectively.

A blown fuse is a common indicator of an issue within an electrical system, such as an overload or a short circuit. Symptoms of a blown fuse can include loss of power to a specific device, circuit, or area of the building. First, replace a blown fuse, turn off the power to the circuit, remove the faulty fuse, and install a new fuse with the same rating. It is essential to identify and address the cause of the blown fuse to prevent further issues.

Fuse boxes and circuit breakers are protective devices that safeguard electrical systems but function differently. A fuse box contains fuses that melt and break the circuit when excessive current flows through them, while a circuit breaker is a reusable switch that trips and interrupts the flow of current when it detects an overload or short circuit. Circuit breakers are generally more convenient and safer as they can be reset, unlike fuses that need replacement after blow.

To identify a fuse in an electrical panel, look for small, cylindrical or rectangular devices with metal caps on either end or a transparent window that reveals the element. Fuses are typically labelled with their ratings, making it easier to select the appropriate replacement if needed.

How is a fuse different from a circuit breaker?

A fuse and a circuit breaker are electrical safety devices designed to protect electrical circuits and devices from damage due to excessive current caused by overloads or short circuits. However, they function differently and have distinct features that set them apart:

- Functioning mechanism: A fuse consists of a metal wire or strip that melts and breaks the circuit when too much current flows through it. Once it has blown, it must be replaced with a new fuse. On the other hand, a circuit breaker is an electromechanical switch that trips and interrupts the flow of current when it detects an overload or short circuit. Unlike a fuse, a circuit breaker can be reset after it trips, restoring the electrical circuit without needing replacement.

- Reusability: Fuses are single-use devices that must be replaced after a blow. However, circuit breakers are reusable and can be reset after tripping, making them more convenient and cost-effective in the long run.

- Responsiveness: Circuit breakers generally trip faster than fuses in response to overloads or short circuits. This quicker response can be advantageous when rapid protection is crucial to minimize damage to electrical components.

- Selectivity: Circuit breakers offer a wider range of current ratings and can provide more precise protection for various electrical loads. Some advanced circuit breakers also have adjustable settings, allowing for better customization of the protection level.

- Cost: Fuses are generally less expensive than circuit breakers upfront. However, since circuit breakers can be reset and reused, they may be more cost-effective, especially when electrical faults occur frequently.

- Size and form factor: Fuses are typically smaller and available in various shapes and sizes, such as cylindrical or blade-type designs. Circuit breakers are generally larger and housed in a box or panel, often with a switch-like appearance.

- Indicator: Some circuit breakers have a visual indicator, such as a trip flag, to show when they have tripped. On the other hand, fuses may require inspection or testing to determine if they are blown, although some designs have a transparent window to check the element visually.

What is a fuse?

While both fuses and circuit breakers serve the same purpose of protecting electrical circuits from excessive current, they differ in their functioning mechanisms, reusability, responsiveness, selectivity, cost, size, and visual indication. Therefore, choosing between a fuse and a circuit breaker depends on the specific application, budget, and preferences for convenience and maintenance.

EF PARTNER MEDIA

Photocontrol Failsafe Technology for Outdoor LED Lighting

Build-Your-Own Acorn

Shared Media

OMICRON StationGuard

OMICRON DANEO 400

OMICRON CPC 80 + CP TD12/15

OMICRON MPD 800

EasyPower 138-page Practical Solution Guide To Arc Flash Hazards, Third Edition

Intelligent Power Today. 2021 Issue 1

Electric Motors Handbook Vol. 1

Electric Motors Handbook Vol. 2

Electric Motors and Drives Handbook, Vol. 5

Electrical Motors & Drives Handbook Vol. 3

Electric Motors and Variable Frequency Drives Handbook Vol. 4

Variable Frequency Drives Handbook Volume 1

What Is A Fuse? Protective Device On-Line Buyer's Guide

The Electricity Forum Online Industrial Electrical Power Buyer's Guide is an interactive reference tool for buyers and specifiers, providing information on equipment, companies, products and services for North America's electrical industry. Search through hundreds of leading Suppliers and thousands of product categories. Add Your Company Today!

Free What Is A Fuse? Protective Device Magazine Subscription

The Electricity Forum is a North American "value added" publisher of Transmission & Distribution print/digital magazine: Electricity Today - a leading electrical transmission and distribution magazine. Magazine is distributed FREE of charge to North American electrical industry professionals.

Contribute To The Electricity Forum

The Electricity Forum is interested in publishing your technical, non-commercial articles, on a wide variety of subjects. We are seeking original content for our Transmission and Distribution Channels. Click here to view our author guidelines and submit your article today!

LIVE ONLINE FORUM

POWER TRANSFORMER TECHNOLOGIES

February 28, 2024 – 01:00 PM ET

Register for FREE

Join us for this free live forum sponsored by many companies

Be informed and ask questions in a live platform, secure your seat now

Can't attend live? Simply register and we'll send you a recording

- Network Sites:

- Technical Articles

- Market Insights

- Or sign in with

- iHeartRadio

How Does a Fuse Work? Understanding the Details of Fuse Operation and Implementation

Join our engineering community sign-in with:.

This article provides an overview of some subtle yet important aspects of fuse functionality and design.

Related Information

- AAC textbook page on fuses

- Axial, Cartridge, Surface Mount, PTC...: The Many Types of Fuses

The Basics: How Does a Fuse Work?

A fuse is a simple and highly effective way to protect a device from dangerous levels of current:

- Current flowing through a conductor’s nonzero resistance leads to power dissipation.

- Power is dissipated in the form of heat.

- Heat raises the temperature of the conductor.

- If the combination of current amplitude and duration is sufficient to raise the temperature above the fuse’s melting point, the fuse becomes an open circuit and current flow ceases.

Though the fundamental operation of a fuse is not complicated, there are subtle points to keep in mind. The rest of this article will help you to understand some important details related to the behavior and use of fuses.

How a Fuse Is Tripped: Heat, Not Current

A fuse is not tripped directly by current; rather, the current creates heat, and heat trips the fuse. This is actually a rather important distinction because it means that fuse operation is influenced by ambient temperature and by the temporal characteristics of the current.

The specified current rating of a fuse is relevant only to a specific ambient temperature (usually, or maybe always, 25°C), and consequently you need to adjust your fuse selection if you’re designing a device that will operate outdoors in, say, Antarctica or Death Valley. The following plot shows how ambient temperature affects the actual current rating—relative to the nominal 25°C current rating—of three types of fuses.

Plot taken from this document published by Littelfuse .

Regarding the temporal characteristics of the current passing through the fuse, we all know that the effect of heat accumulates over time (momentarily touching a hot skillet is nothing compared to picking it up and realizing that it’s hot when you’re halfway between the stove and the dining table). Consequently, the current rating of a fuse is a simplification of its real behavior. We can’t expect a fuse to respond to high-amplitude transients because the short duration of the higher power dissipation doesn’t increase the temperature enough to cause tripping.

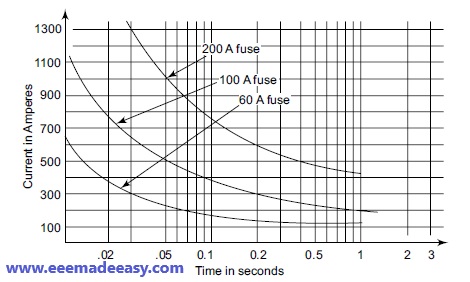

The following plot shows the time-current characteristics for a group of surface-mount fuses made by Panasonic. The rated current is on top, and the curve represents the amount of time required to trip the fuse in relation to the amount of current flowing through the fuse.

Plot taken from this datasheet .

As you can see, transient amplitudes must be much higher than the rated current. For example, you need 3 amps to trip a 0.5-amp fuse when the duration of the overcurrent condition is only 1 ms.

Connect Fuses In Series!

I’m not going to dwell on this point because it’s so straightforward, but it’s worth mentioning just in case you’re up late designing a schematic and in your exhausted state you don’t notice that you placed the fuse in such a way that it is, for example, in series with only one of two voltage regulators. A fuse cannot protect anything that is connected in parallel with it.

Fuse Design Best Practices: Rated Current vs. Operating Current

It would be perfectly reasonable to assume that a fuse rated for 6 amps could be used in a circuit that might need 5 amps of steady-state current. It turns out, though, that this is not good design practice.

The current rating of a fuse is not a high-precision specification, and furthermore (as discussed above) the actual tripping current is influenced by ambient temperature. Consequently, to avoid “nuisance tripping,” you should have a fairly generous gap between your expected steady-state current and your fuse’s rated current.

This document from Littelfuse suggests a “rerating” of 25% (for operation at room temperature); thus, a fuse with a rating of 10 amps would be used only if the circuit’s steady-state current will stay below 7.5 amps.

You Have to Be Patient

Let’s say your circuit includes a delicate component that will certainly be damaged if it is subjected to currents higher than 1 amp. The circuit should never draw more than 500 mA under normal conditions, so you include a fuse with a rating of 900 mA. This is high enough to prevent nuisance tripping and low enough to ensure that the delicate component never sees 1 amp. Right?

Well, no. Consider the following spec for the Panasonic fuses mentioned earlier in the article:

Image taken from this datasheet .

We’ve already discussed the fact that heat takes time to accumulate—in this case, it takes a long time. You’ll have to wait at least four hours for the fuse to trip when the current is equal to the rating. Even at twice the rated current, the delay is at least five seconds. The bottom line is that the delicate component might be toast long before the fuse trips.

You’ll have to rethink your fuse selection or—and this is probably a more practical solution in a situation such as the one described above—implement a different method of dealing with overcurrent conditions.

Why Do Fuses Have a Voltage Rating?

Fuses are designed to have very low resistance so that they don’t unduly interfere with the circuits that they are protecting. This low resistance means that the voltage drop across the fuse will be very small. Why, then, do fuses have a voltage rating?

It’s true that fuses see small voltage during normal operation, but the voltage rating is not relevant to normal operation. Rather, the voltage rating tells you what the fuse can endure after it has tripped . A blown fuse is an open circuit, and if the voltage across this open circuit is enough to cause arcing, the fuse can’t be relied upon.

It’s a good idea to keep an eye on voltage ratings if you’re using tiny surface-mount fuses , such as the one shown below (note how thin the actual fusing element is). The rating for an 0603 fuse, for example, could be 32 V or even 24 V.

Diagram taken from this datasheet .

We’ve covered some interesting details about how fuses work and how to effectively incorporate them into our designs. Check out my other article on different types of fuses to learn more.

Related Content

- Hoverboards: How Do They Work?

- Solenoids: Understanding Actuation and Voltage Polarity

- Understanding Memory: How to Use Structures in Embedded C Language

- How to Ensure MultiGigabit Automotive Ethernet Compliance

- Driving Towards Level 3 Automation, Understanding the Importance of Sensing Modalities, Perception and Fusion

- Wireless Basics: How Radio Waves Work

Learn More About:

- circuit protection

- overcurrent protection

- overcurrent

You May Also Like

Ymin MPS Series in Data Center Application

In Partnership with Ymin

A Guide to Effective Probe Selection for Low Noise Power Integrity Measurements

by Benjamin Dannan, Signal Edge Solutions

Low Power Image Sensors Revolutionize Vision System Design and Efficiency

Introduction to the Common-Drain Amplifier: Small-Signal Behavior

by Nicholas St. John

New Proposals Vie for CHIPS Act Funds for Fabs and Digital Twin R&D

by Aaron Carman

Welcome Back

Don't have an AAC account? Create one now .

Forgot your password? Click here .

What is Fuse? | Types of Fuses and their Applications

Fuse is a component that allows current to pass under normal circumstances and opens automatically if the current exceeds a specified value.

In some ways, a fuse is like a normally closed switch. A fuse is designed to allow current to pass under normal circumstances. However, unlike a normally closed switch, a fuse is designed to open automatically if the current exceeds is specified value. The simplest type of fuse and its schematic symbols are shown in Figure 1 .

FIGURE 1 A cartridge fuse and its schematic symbol

As current passes through a conductor, heat is produced. The amount of heat varies directly with the value of current. That is, as current increases, so does the amount of heat it produces.

The fuse in Figure 1 is called a Cartridge Fuse. It contains thick conductor that is designed to melt at relatively low temperatures. If the current through the component reaches a specified level, the conductor heats to its melting point. When it melts, the connection between the ends of the fuse is broken, the fuse is destroyed, and it effectively acts as an open switch.

The purpose of the fuse is to protect a circuit or system from excessive current. For this reason, a fuse is normally placed between a power source and the circuit or system it is designed to protect, as shown in Figure 2 . As you can see, the total circuit current provided by the power source in Figure 2 passes through the fuse.

As long as the fuse is good, the current path is complete. However, if the problem develops that causes the circuit current to exceed the rating of the fuse, the component opens and the current path is broken. This protects the circuit from excessive current.

FIGURE 2 Fuse position in a basic circuit.

Fuse Ratings

Fuses have a current rating and a voltage rating.

The current rating of a fuse is the maximum allowable fuse current. If the current rating of a fuse is exceeded, the fuse will “Blow” (open).

In order for you to understand the voltage rating of a fuse, we must establish one of the characteristics of an open circuit. In an open circuit, the applied voltage is felt across the open. For example, consider the circuit shown in Figure 3a . The applied voltage has a value of 50 VDC. A difference of potential exists between points A and B. This difference of potential is equal to the applied voltage, 50 VDC.

FIGURE 3 Circuit voltages with a good fuse and an open fuse.

The voltage rating of the fuse is the maximum amount of voltage that an open fuse can block.

The explanation of this rating starts with the circuit in Figure 3b . As you can see, the fuse in the circuit has opened. Once it has opened, the applied voltage (50 VDC) is felt across the fuse. You may recall that the average breakdown voltage of an insulator is the difference of potential that will cause the insulator to break down and conduct. The voltage rating of a fuse is basically the same thing.

If the voltage across an open fuse exceeds its voltage rating, the air in the fuse may ionize (charge), causing the open fuse to conduct again. For example, consider the two circuits in Figure 4 . In Figure 4a , the applied voltage is less than the voltage rating of the fuse.

FIGURE 4 Voltages across open fuses.

In this case, the open fuse does not allow conduction, and the circuit is protected. However, the applied voltage in Figure 4b is greater than the voltage rating of its fuse. Because of this, the open fuse ionized and conducts. The result is that the circuit is no longer protected.

Replacing a Fuse

When a fuse is blown, it must be replaced. When replacing a fuse, these guidelines must be followed:

1. Make sure the circuit is de-energized. For example, if you’re replacing the fuse for a central air conditioning unit, make sure that the unit is switched off at the thermostat.

2. Use an exact replacement. That is, use a fuse that is the same size and has the same current rating as the original fuse.

3. Never replace a fuse with the one that has a higher current rating!

The first of three guidelines is designed to protect both you and the circuit. Replacing the fuse with the system energized can result in surge of current. Not only could this surge hurt you, it could also severely damage the system. The second guideline needs no explaining. A replacement fuse should never allow a higher current then the original fuse.

The third guideline is critical. If you replace a fuse with one that is higher current rating, you run the risk of damaging the circuit and potentially starting a fire. As you know, current produces heat. If you replace a fuse with one that has a higher current rating, a problem could cause more current to be drawn through the circuit than it was designed to handle. The resulting heat could destroy the circuit and could even result in fire.

Once the fuse has been replaced, one of two things will happen:

1. The circuit operation will return to normal, or.

2. The new fuse will blow when power is restored.

If the circuit operation returns to normal, then the problem was likely nothing more than an old or defective fuse. If the new fuse blows, then there is a problem that is causing excessive current to be drawn from the power source. In this case, the problem must be diagnosed and repaired before attempting to replace the fuse again.

Types of Fuses: Electronic Applications

Three types of fuses are found in electronic systems; high speed instantaneous, normal instantaneous and time delay. As you have probably guessed, these categories rate fuses in terms of the time required for them to blow.

High speed instantaneous fuses react faster to an OVERLOAD (excessive current) condition, than any other type of fuse. High speed instantaneous fuses are also known as fast acting or quick acting fuses.

Normal instantaneous fuses are somewhat slower to respond to an overload condition. Normal instantaneous fuses are also known as instantaneous or normal blow fuses.

Time delay fuses have the same time lag ratings as normal blow fuses, but they can handle short term overloads without blowing. Many applications (such as microwave ovens) produce a current surge when they turn on. If the time delay fuse is in the circuit of such an appliance, the current surge will not blow the fuse, Note that time delay fuses are also known as lag or slow blow fuses .

Fuses come in a variety of types and sizes, as described in Table 1 . Note that the type, current, voltage ratings are commonly identified on the body or the fuse.

Table 1: Common Cartridge Fuses

Types of Fuses: Electrical Applications

Electrical fuses are contained in fuse boxes like the one shown in Figure 5 . When a working fuse is installed, it connects the AC line input to the rest of the circuit.

Figure 5: A fuse panel.

There are several types of fuses; cartridge, type T, type S, and blade. The fuses described previously are all cartridge fuses, as shown in Figure 1 , a cartridge fuse is the one that has a tube shaped body.

A Type T Fuse has an Edison base. As shown in Figure 6a , the Edison base resembles the base of a light bulb. This type of fuse screws directly into a standard fuse socket.

Figure 6: Common electrical fuses. (a) Type T Fuse. (b) Type S Fuse

A Type S Fuse is shown in Figure 6b . The base on the type S fuse is called a rejection base. A rejection base requires the use of an adaptor is installed in a fuse socket. Once the rejection base adaptor is installed in a fuse socket, it cannot be removed.

Type S fuses with different current ratings have different threads. For example, a 30A fuse will not fit in the adaptor for a 15A fuse. This makes it impossible for the type S fuse to be replaced by one with a different current rating. Note that rejection bases are also referred to as Tamperproof bases. The basic characteristics of Type T and Type S fuss are summarized in Table 2.

Table 2: Type T and Type S Fuses

Blade fuses are commonly used in automotive applications. Several blade fuses and fuse holders are shown in Figure 7 .

FIGURE 7 Blade fuses and fuse holder.

- A fuse is a component that allows current to pass so long as it remains below the fuse current rating.

- If circuit current exceeds the fuse rating, the fuse opens (blows) and current is blocked.

- Fuses are rated for both current and voltage. The current rating is the maximum current the fuse will allow before it opens. The voltage rating is the maximum voltage that the fuse can withstand before it begins to conduct even if it is blown.

- A T-type fuse screws into a service panel in the same way as a light bulb. This is referred to as an Edison base. An S-type fuse has what is called a rejection base, and requires an adaptor to fit into a standard fuse socket. Different fuse ratings have different threads, so you cannot install the wrong fuse in this socket.

Navigation menu

A fuse is an electrical safety device that protects an electric circuit from excessive electric current . Fuses are destroyed during overload conditions. When reasonable to do so (and economically sensible), circuit breakers are used instead because they are not destroyed during overload conditions. It's cheaper to install fuses than circuit breakers, but since fuses need to be replaced and circuit breakers don't, fuses have a higher operational cost .

Practical tips

Houses have fuses in fuseboxes (see figure 1). Here are some helpful household tips for homes with a fuse box.

- Never replace a fuse with a larger fuse, as this will let too much current through and be a fire hazard.

- Replacing a fuse with a smaller-sized fuse is also a problem because this will prevent normal operation.

- Never use something other than a fuse to replace a fuse; this will quite likely cause a fire.

- Keep extra fuses around the house to quickly replace blown fuses.

- Know where your fuse box (see figure 1) is.

- Turn off or unplug items in use before replacing a blown fuse; otherwise, the replacement fuse will be immediately destroyed as well.

How fuses work

Fuses are designed to allow current through the circuit, but in the event that the current exceeds some maximum value it will burn out the wire , so that there is no longer a circuit . The current that will cause a fuse to blow is called the current rating . Fuses also have a voltage rating; this is the maximum voltage difference that the fuse can block. Once a circuit is open (broken), an applied voltage exists at the ends of the fuse, and if this voltage exceeds the voltage rating of the fuse, the air in the fuse may ionize and start conducting again, therefore leaving the circuit without a safety system.

Types of fuses

Fuses are housed in fuse boxes (see figure 1) and listed in the table below. [2]

| Fuse type | Description | Picture |

|---|---|---|

| Cartridge | Contains a thin conductor designed to melt at a low temperature. Once the current reaches a level that can generate enough heat to match or surpass the designed melting point, the connection will break. | A normal cartridge fuse and a slo-blo fuse |

| Blade | Contains two electrical connectors that plug into a circuit and a wire inside that will melt at a certain current. | Blade fuses . |

| Plug | Screwed directly into a standard fuse socket. To learn more about this type of fuse please see . | A plug fuse and its base |

| Adapter | Referred to as a rejection base (also called type-S), it requires an adapter to fit into a standard fuse socket. Once it is installed it cannot be removed. Fuses with different current ratings will have different threads; therefore, they cannot be replaced with a fuse of a different current rating. To learn more about this type of fuse please see . | An adapter fuse and its base |

There are special fuses which handle short periods of overloads by deliberately reacting slowly, called time delay fuses. They can normally be found in a household microwave, which produces a current surge when it is turned on. See here to learn more about time delay fuses.

For Further Reading

For further information please see the related pages below:

- Electric circuit

- Circuit breaker

- Ground fault circuit interrupter

- Electrical outlet

- Or explore a random page!

- ↑ This picture contributed by someone on the team.

- ↑ R.T. Paynter, “Basic Electric Components and Meters,” in Introduction to Electricity , 1st ed. NJ: Prentice-Hall, 2011, ch. 3, sec. 3.6, pp. 98-107.

- ↑ (2014, Nov. 24). Fuses and Breakers [Online]. Available: http://hyperphysics.phy-astr.gsu.edu/hbase/electric/bregnd.html

- ↑ (2014, Nov. 24). Blade Type Fuses [Online]. Available: http://www.thefusecompany.net/BladeType.htm

- ↑ (2014, Nov. 24). Plug Fuses [Online]. Available: http://epb.apogee.net/foe/fsgofpf.asp

- ↑ (2014, Nov. 24). Type S/Adapter Fuses [Online]. Available: http://epb.apogee.net/foe/fsgotsf.asp

Premium Membership ♕

Save 10% on Pro Membership Plan with coupon RCSE10 and study specialized LV/MV/HV technical articles and papers.

Fuses – Principles of design and operation

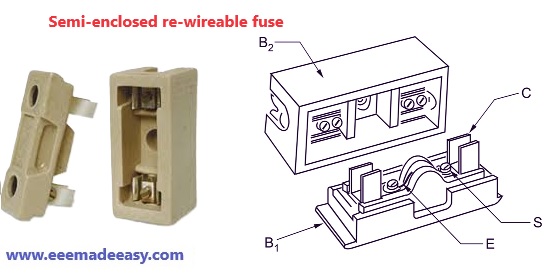

The larger the wire cross section , the larger is the current that the fuselink will carry without operating. In the UK, fuses of this type are specified for use at voltages up to 250 V and currents up to 100 A. They are known as semi-enclosed or rewireable fuses.

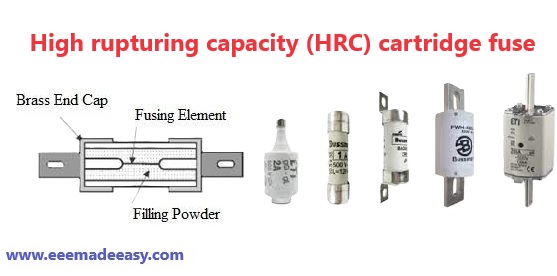

The most common fuselink is the cartridge type. This consists of a barrel (usually of ceramic) containing one or more elements which are connected at each end to caps fitted over the ends of the barrel. The arrangement is shown in Figs 2 and 3. If a high current breaking capacity is required, the cartridge is filled with sand of high chemical purity and controlled grain size. The entire fuselink is replaced after the fuse has operated and a fault has been disconnected. Cartridge fuses are used for a much wider range of voltages and currents than semi-enclosed fuses.

Fuselinks can be divided into current-limiting and non-current-limiting types. A sand-filled cartridge fuselink is of the current-limiting type; when it operates, it limits the peak current to a value which is substantially lower than the prospective current. A non-current-limiting fuse, such as a semi-enclosed fuse, does not limit the current significantly. The element shown in Fig. 2 is a notched tape. Melting occurs first at the notches when an overcurrent flows and this results in a number of controlled arcs in series. The voltage across each arc contributes to the total voltage across the fuse, and this total voltage results in the current falling to zero. Because the number of arcs is limited, the fuselink voltage should not be high enough to cause damage elsewhere in the circuit.

The characteristic development of current and voltage during the operation of a fuse is shown in Fig. 8.6 . The function of the sand is to absorb energy from the arcs and to assist in quenching them; when a high current is disconnected, the sand around the arcs is melted.

Fig. 1 Fuse holders for miniature and compact LV fuses

The element is usually of silver because of its resistance to oxidation. Oxidation of the element in service would affect the current that could be carried without melting, because the effective cross section of the element is changed. Silver plated copper elements are also used.

Many elements include an m-effect blob, which can be deposited on wire (Fig. 1 b) or notched tape. The blob is of solder-type alloy which has a much lower melting point than the element. If a current flows which is large enough to melt only the m-effect blob, the solder diffuses into the silver. This creates a higher local resistance in the element and the fuse operates at a lower current than it would have done in the absence of the blob.

Other types include the expulsion fuse which is used at high voltage, and the universal modular fuse (UMF) which is used on Printed Circuit Boards (PCBs). Fuses offer long life without deterioration in their characteristics or performance, and cartridge fuses have the particular advantage that they contain the arc products completely.

Related electrical guides & articles

Premium membership, edvard csanyi.

Please help mathematical model for fuse designing

Why arcing period time longer than pre_arcing period?

Very informative and useful post, both for students and engineering professionals. Highly recommended.

i read the article its very knowledgeable and its good for the enginneering students and proffessionals

Leave a Comment

Tell us what you're thinking. We care about your opinion! Please keep in mind that comments are moderated and rel="nofollow" is in use. So, please do not use a spammy keyword or a domain as your name, or it will be deleted. Let's have a professional and meaningful conversation instead. Thanks for dropping by!

Your real name *

Email address *

Prove that you are not a robot. 2 × = fourteen

Learn How to Design Power Systems

Subscribe to weekly newsletter.

Edukatronik.com

Blown Away: Understanding the Basics of Electrical Fuses

Home / Tutorials / Electrical Safety / Electrical Fuses

Electrical fuses play a crucial role in ensuring electrical safety. They are designed to protect electrical systems and equipment from overcurrents and short circuits, which can lead to electrical fires and damage.

Without fuses, electrical systems would be at risk of overheating and causing serious harm. In this article, we will explore how they function, their characteristics, the most popular types, how to choose the best fit for you and the common causes of fuse failure.

What does an electrical fuse do?

An electrical fuse is a protective device that is designed to interrupt the flow of current in a circuit when the current exceeds a certain level. It consists of a metal wire or strip that melts when exposed to excessive current, breaking the circuit and preventing the flow of electricity.

When an excessive amount of current flows through a circuit, the fuse wire heats up due to its resistance. Once the temperature reaches a critical point, the wire melts and breaks the circuit. This action protects the electrical system from potential damage.

The purpose of a fuse is to protect electrical systems and equipment from damage caused by overcurrents and short circuits .

How are electric fuses wired?

To wire an electrical fuse, first, determine the maximum current your circuit can handle and choose a fuse with a matching or slightly higher rating. Install a fuse holder, connecting the incoming hot wire to the “in” terminal and the outgoing hot wire to the “out” terminal.

The fuse, placed in the hot wire, acts as a protective device, interrupting the circuit in case of overcurrent to prevent damage. While, the neutral wire, usually connected directly to the electrical fuse panel, completes the circuit by providing a return path for the current.

Below is a diagram of how a fuse should be connected. It is best to place it in front of the load.

Electrical fuse ratings and sizes

When selecting fuses for electrical circuits, you should consider several characteristics to ensure proper protection and reliable operation. Take into account the following important characteristics:

- Current Rating (Amps): this rating refers to the maximum current that the fuse can safely carry under normal operating conditions without opening (blowing). The fuse should be rated higher than the normal operating current of the circuit it is protecting.

- Voltage Rating (Volts): fuses have a voltage rating that indicates the maximum voltage they can safely interrupt. It’s important to choose a fuse with a voltage rating equal to or higher than the voltage of the system.

- Interrupting Rating: this is the maximum current that a fuse can safely interrupt without causing damage. It’s crucial to select a fuse with an interrupting rating equal to or greater than the available short-circuit current in the system.

- Temperature Rating: fuses have temperature ratings that indicate the maximum ambient temperature in which they can operate safely. It’s essential to choose a fuse with a temperature rating suitable for the operating environment.

- Time-Current Characteristics (Time Delay): fuses can be classified as either fast-acting or time-delay (slow-blow). Time-delay fuses allow for temporary overloads without blowing, which is useful for applications with inrush currents, and fast-acting fuses respond faster.

- Physical Size and Form Factor: the physical size and form factor of the fuse are important for proper installation and fitting within the equipment or circuit board. Make sure the selected fuse can fit into the available space.

Common types of electrical fuses and their features

There are several types of electrical fuses available, each with its own features and applications. The most common types include cartridge fuses, plug fuses, blade-type fuses, and thermal fuses.

- Cartridge fuses: they are cylindrical in shape and are typically used in industrial applications. They consist of a metal end cap on each end with a glass or ceramic tube in between. The metal wire or strip is housed inside the tube.

- Plug fuses: also known as Edison base fuses, are commonly found in residential settings. They are designed to fit into screw-in sockets and are used to protect individual circuits. Plug fuses have a threaded metal base with a glass or ceramic body.

- Blade-type fuses: also known as automotive fuses, are used in automotive applications. They have a flat, blade-like shape and are designed to fit into fuse holders or fuse boxes. Blade-type fuses come in different sizes and current ratings.

- Thermal fuses: also known as thermal cutoffs or thermal links, are designed to protect against overheating. They consist of a fusible alloy or wire that melts when exposed to excessive temperature. Thermal fuses are used in hair dryers, coffee makers, and irons.

In practice, electrical fuses can be categorized in various ways, as they can be assessed based on numerous characteristics. However, the classification outlined here is the most commonly used.

What are the common causes of electrical fuse failure?

There are several common reasons why electrical fuses fail. The main causes are electrical failures , which include overcurrents, short circuits, damaged wiring, faulty equipment, and improper installation. All of these reasons can cause the current to exceed the fuse rating.

Another common cause of fuse failure is overheating. When there is excessive heat generated in an electrical circuit, it can cause the wire or strip inside the fuse to melt and blow. Overheating can occur due to overloaded circuits , poor ventilation or inadequate cooling.

Improper installation or use of fuses can also lead to fuse failure. Using a fuse with the wrong current rating or voltage rating can cause it to blow prematurely or fail to protect the circuit. Additionally, using a fuse that is not compatible with the specific application can result in fuse failure.

Lastly, environmental factors such as moisture, dust, and corrosion can also contribute to fuse failure. Moisture can cause the fuse contacts to corrode, resulting in poor electrical connections and increased resistance. Dust and debris can accumulate on the fuse contacts, leading to overheating and potential fuse failure.

What happens when a fuse blows?

When a fuse blows, it means that the metal wire or strip inside the fuse has melted, breaking the circuit and stopping the flow of current. This occurs when the current exceeds the rated value of the fuse.

There are several consequences that can occur. First, the electrical system or equipment will stop functioning since the flow of current has been interrupted. This can lead to inconvenience and disruption in operations.

Second, there may be damage to the electrical system due to overheating or short circuits. Lastly, there is a risk of electrical fires if the overcurrents are not properly addressed. Therefore, it is important to identify and address the cause of a blown fuse promptly.

Signs of a blown electrical fuse

If you’re uncertain about whether the fuse has blown, there are several signs that can help you. The most common sign is the loss of power to a specific circuit or equipment. But, it is important to know the other possible signs:

- Loss of power: one of the most obvious signs of a blown electrical fuse is a loss of power to certain areas or appliances in your home. If you notice that certain lights, outlets, or appliances are not working, it could be due to a blown fuse.

- Tripped circuit breaker: if you have a circuit breaker panel instead of fuses, a tripped circuit breaker can indicate a blown fuse. When a circuit is overloaded or short-circuited, the breaker will trip to protect the electrical system.

- Burnt smell: if you notice a burnt smell coming from an outlet or electrical panel, it could be a sign of a blown fuse. This smell is often caused by overheating due to an electrical overload.

- Flickering lights: if your lights are flickering or dimming, it could be a sign of a blown fuse. This can happen when there is too much demand on the electrical system and the fuse cannot handle it.

- Sparking or popping sounds: if you hear sparking or popping sounds coming from an outlet or electrical panel, it could indicate a blown fuse. This is often caused by a short circuit or an overloaded circuit.

- Hot outlets or switches: if your outlets or switches feel hot to the touch, it could be a sign of a blown fuse. This can happen when there is too much current flowing through the circuit.

- Tripping GFCI outlets: if your GFCI (Ground Fault Circuit Interrupter) outlets keep tripping and need to be reset frequently, it could indicate a blown fuse. GFCI outlets are designed to protect against electrical shocks and will trip if there is an imbalance in the electrical current.

- Blown fuses in appliances: if you have multiple appliances that are not working properly or have blown fuses themselves, it could indicate a problem with the electrical system in your home.

- Burnt or melted fuses: if you inspect the fuses in your electrical panel and notice that they are burnt or melted, it is a clear sign of a blown fuse. This can happen when there is an electrical overload or short circuit.

- Continuously tripping fuses: if your fuses keep tripping and need to be replaced frequently, it could indicate a larger issue with your electrical system. It is important to have a professional electrician inspect and repair the problem to prevent further damage or safety hazards.

Safety precautions when dealing with electrical fuses

When working with electrical fuses, it is important to take safety precautions to prevent electrical accidents and injuries. Here are some safety measures to consider:

- Always turn off the power before working on electrical circuits or equipment. This can be done by switching off the circuit breaker or override the electrical fuse panel.

- Use appropriate personal protective equipment (PPE) such as insulated gloves and safety glasses when handling fuses.

- Ensure that the electrical system or equipment is properly grounded to prevent electric shocks.

- Do not touch the metal parts of a blown fuse as they may still be live and pose a risk of electric shock.

- Use insulated tools when removing or replacing fuses to prevent accidental contact with live parts.

- Avoid overloading circuits by distributing loads evenly across multiple circuits.

- Regularly inspect and maintain electrical systems and equipment to identify any potential issues that could lead to blown fuses.

- Follow manufacturer’s guidelines and specifications when selecting and installing fuses.

- If you are unsure about how to safely work with electrical fuses, consult a qualified electrician for assistance.

- Taking these safety precautions will help minimize the risk of electrical accidents and ensure the safe handling of electrical fuses.

The importance of electrical fuses

In conclusion, electrical fuses play a vital role in ensuring electrical safety . They protect electrical systems from overcurrents, short circuits, and potential fires. Fuses interrupt the flow of current when it exceeds a certain level, preventing further damage to the electrical system.

Overall, electrical fuses are essential in protecting electrical systems and equipment. They provide a cost-effective solution for ensuring electrical safety and preventing damage to electrical systems.

By understanding the function and characteristics of fuses, as well as following safety precautions, we can effectively utilize fuses to protect our electrical systems and promote electrical safety.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

EEE Made Easy

Fuse|Electrical Fuse

Fuse: A fuse is an electrical safety device that operates to provide overcurrent protection of an electrical circuit. The essential component of Fuse is a metal wire or strip that melts when too much current flows through it, thereby stopping or interrupting the current.

A fuse is a short piece of wire or a thin strip of metal, which is inserted in series to the circuit.

When the fault current flows through the fuse for a sufficient time, it melts the fuse, thus isolating the circuit.

Join EEE Made Easy Telegram channel

Working of Fuse

Under normal operation, the fuse is kept at a temperature below the melting point of the material used, which helps in carrying the normal current without any rise in temperature.

But when fault occurs in the power system due to a short circuit or when an overload current, which is greater than the normal current, flows through the fuse, this fault current will increase the temperature above the melting point of the material used for the fuse.

Hence, the material melts or blows, thereby isolating the healthy part and protects the circuit.

The magnitude of excessive current flowing in the circuit is an important factor in deciding the time taken for melting or blowing out the fuse.

Greater the fault current, lesser the time required to melt or blow out the fuse.

The inverse time-current characteristics of a fuse are shown in Figure below.

Advantages and Disadvantages of Fuse

The advantages and disadvantages of fuse are given as follows:

Advantages of Fuse

- Cheapest form of protection device.

- Requires no maintenance.

- Operation of fuse is completely automatic.

- Easily breaks a large amount of fault current.

- Pollution-free protection device i.e., does not create any smoke or noise.

- Suitable for over-current conditions due to its inverse current–time characteristics.

- Requires less time for isolating the faulty part of the circuit.

Disadvantages of Fuse

- Rewiring or replacing a fuse takes a considerable time.

- Discrimination between fuses connected in series is not possible.

- Correlation of the characteristics of fuse with the protected device is not always possible.

Download & Install EEE Made Easy App

Desirable Characteristics of Fuse Element Materials

The desirable characteristics of the material used for the fuse to perform satisfactorily are:

- Low melting point, e.g., tin, lead

- High conductivity, e.g., silver, copper

- Least reactive to oxidation, e.g., silver

- Affordable, e.g., lead, tin, copper

It can be noted that no element possesses all the desirable characteristics of a fuse and hence a compromise is to be made in selecting a material for the fuse.

Lead, tin, copper, zinc and silver are the most commonly used fuse materials.

Tin, or an alloy of lead and tin (0.37 and 0.63 respectively) is used as a fuse element material, where the rating of current is up to 10 A.

For larger currents, copper or silver is used as fuse element material. Usually, the copper is tinned to prevent oxidation effect.

Zinc, in strip form, is used where a considerable time-delay is required.

silver as a fuse element

In day-to-day activities, silver is used as a fuse element due to the following characteristics:

- Silver Does not get affected or deteriorate when used in dry air.

- As the expansion coefficient of silver is very small, it can carry the rated current continuously for a long time.

- Conductivity is very high.

- Instantaneous transition to vapour state from melting state, when compared to other materials, is possible due to low specific heat.

- Faster operation is possible at higher currents.

- Quick interruption of fault current is possible as the element vaporises at a temperature much lower than the temperature required to ionize it.

How to choose a Fuse?

The time-delay fuses for inductive load and fast acting fuses for the resistive load.

from the appliance manual, Check the power(watts) of the appliance ,voltage rating

The voltage must be greater than the circuit voltage for the proper protection of the device.

Fuse rating = (watts/volts) x 1.25

Use the next highest fuse rating after the calculation.

For example, if the calculated fuse rating is 8.634 Amps, so for this choose a 9 Amp fuse.

Important Terms Fuse

Following are the terms required in fuse analysis:

Current rating of fuse element

Current rating of fuse element is the amount of current that the fuse element can carry under normal operation, without overheating or melting. It depends on temperature rise in the fuse holder, the fuse material and the surroundings of the fuse.

Fusing current

Fusing current is the minimum current at which the fuse element melts or blows away and isolates the healthy portion of the power system.

It is higher than the current rating of the fuse element.

Fusing factor

Fusing factor is the ratio of the fusing current to the current rating of fuse element and its value is always greater than 1.

Prospective current

Prospective current is the RMS value of the fault current, which is obtained by replacing the fuse with a conductor of negligible resistance.

Cut-off current of Fuse

Cut-off current is the maximum value of fault current obtained before the fuse element melts.

Pre-arcing time of Fuse

Pre-arcing time: The time taken to cut off the fault current from its commencement is known as pre-arcing time.

Arcing time of Fuse

Arcing time: The time taken to extinguish the arc after the pre-arcing time is known as arcing time.

Total operating time of Fuse

● Total operating time is the summation of pre-arcing and arcing time.

Breaking capacity

Breaking capacity: The RMS value of the maximum prospective current, which a fuse can deal at rated voltage, is known as breaking capacity.

Types of Fuses

The general classification of fuses is given as follows:

- Low-voltage fuses ● Semi-enclosed re-wireable fuse ● High rupturing capacity (HRC) cartridge fuse with and without tripping device

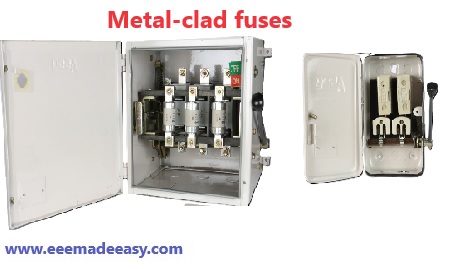

- High-voltage fuses ● Cartridge type ● Liquid type ● Metal-clad fuses

Semi-enclosed re-wireable fuse (Kit-Kat Fuse)

In this type the fuse element is semi – enclosed i.e. neither open nor totally closed

High rupturing capacity (HRC) cartridge fuse

Cartridge type Fuse

Liquid type Fuse

Metal-clad fuses

Comparison Between Circuit Breaker and Fus

| Specification | Circuit Breaker | Fuse |

|---|---|---|

| Function | Performs interruption function | Performs detection and interruption functions |

| Operation | Requires more equipment for automatic operation. | Requires less equipment for full automatic operation |

| Breaking capacity | Very large | Small |

| Operating time | Large (0–1 or 0–2 sec) | Very small (0.002 sec) |

| Replacement | It need not be replaced after its operation. | Requires continuous replacement after every operation. |

Difference between Fuse and Circuit breaker|Fuse vs Circuit Breaker

Difference between Isolator and Circuit breaker|Isolator Vs Circuit breaker

Latest Posts EEE Made Easy

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

https://studynlearn.com/

Electric fuse: working principle and functions and uses.

An electric fuse is a kind of safety device used to limit the flow of current in a functional electric circuit. Whenever there is an excess flow of current or electric current overload through the circuit, the fuse melts down thus breaking the electric circuit and avoid a short circuit.

Wires made from some special materials melt quickly and break when large electric currents are passed through them. These wires are used for making electric fuses. In all buildings, fuses are inserted into all electrical circuits. There is a maximum limit on the current that can safely flow through a circuit.

If by accident the current exceeds this safe limit, the wires may become overheated and may cause a fire. If a proper fuse is there in the circuit, it will blow off and break the circuit. A fuse is thus a safety device that prevents damages to electrical circuits and possible fires.

Fuses of different kinds are used for different purposes. Fuses are generally used the nichrome wire, tie a thin strand of in electrical appliances.

One reason for excessive currents in electrical circuits is the direct touching of wires. This may happen if the insulation on the wires has come off due to wear and tear. This may cause a short circuit.

Another reason for excessive current can be the connection of many devices to a single socket. This may cause overload in the circuit. You might have read reports in newspapers about fires caused by short circuits and overloads.

These days Miniature circuit breakers (MCBs) are increasingly being used in place of fuses. These are switches that automatically turn off when the current in a circuit exceeds the safe limit. You turn them on and the circuit is once again complete.

Working Principle of Fuse

The working of electric fuse is based on heating effect of electric current. An electric fuse is composed of thin metallic wire of non flammable material.

Whenever there is an overload of electric current, the heat generated by the circuit leads to the melting of the fuse (an electric fuse has a low melting point) and protection of the electric circuit.

Functions of Electric Fuse

Let us understand the important functions of electric fuse.

- Prevents fire, breakdown and protects electrc wiring.

- Restricts the flow of current.

- Terminates the circuit when too many appliances are connected in a single circuit and overloading of electric current happens.

- Prevents blackouts.

- Prevents damage that can happen due to mismatched loads.

- A fuse acts like a circuit breaker and prevents us from electrocution!

Read More- Heating Effect of Electric Current: Definition and Applications

- May,19 2021

Leave your comment

Reply Comment

Electrical Power & Fuses ( Edexcel IGCSE Physics )

Revision note.

Electrical power

- Power is defined as

The rate of energy transfer or the amount of energy transferred per second

- The voltage (potential difference) of the device

- The current of the device

- The power of an electrical component (or appliance) is given by the equation:

- P = power, measured in Watts (W)

- I = current, measured in amperes (A)

- V = potential difference, measured in volts (V)

- The unit of power is the Watt (W), which is the same as a joule per second (J/s)

A formula triangle can help rearrange the electrical power equation

Power, current, voltage formula triangle

- For more information on how to use a formula triangle refer to the revision note on Speed

Worked example

Calculate the potential difference through a 48 W electric motor with a current of 4 A.

Step 1: List the known quantities

- Power, P = 48 W

- Current, I = 4 A

Step 2: Write down the relevant equation

Step 3: Rearrange for potential difference, V

Step 4: Substitute the values

Remember: Power is just energy per second . Think of it this way will help you to remember the relationship between power and energy. You can remember the unit by the phrase: “ Watt is the unit of power ?”

Selecting fuses

- A fuse is a safety device designed to cut off the flow of electricity to an appliance if the current becomes too large (due to a fault or a surge)

Fuse circuit symbol

The circuit symbol for a fuse - take care not to confuse this with a resistor

- Fuses usually consist of a glass cylinder containing a thin metal wire

- The wire heats up and melts

- This causes the wire to break , breaking the circuit and stopping the current

- This makes sure that more current doesn't keep flowing through the circuit and causing more damage to the equipment, or, causing a fire

- In order to select the right fuse for the job, the current through an appliance needs to be known

- If the electrical power of the appliance is known (along with mains voltage ), the current can be calculated using the equation:

- I = current in amperes (A)

- P = power in watts (W)

- V = voltage in volts (V)

- Because of this, the rule of thumb is to always choose the next size up

- If the fuse current rating is too low, it will break the circuit even when an acceptable current is flowing through

- If the fuse current rating is too high, it will not break the circuit in enough time before damage occurs

If an appliance uses a current of 3.1 A, what would be a suitable rating for a fuse?

Step 1: Consider a 3 A fuse

- The fuse would blow as soon as the appliance was switched on

Step 2: Consider a 5 A fuse

- It is the next size up from the current required

Step 3: Consider a 13 A fuse

- It would allow an extra 10 amperes to pass through the appliance before it finally blew

Remember there are two steps involved in selecting a correctly sized fuse for an appliance:

1. Calculating the current required using the electrical power equation

2. Selecting the next size up fuse

You've read 0 of your 10 free revision notes

Unlock more, it's free, join the 100,000 + students that ❤️ save my exams.

the (exam) results speak for themselves:

Did this page help you?

- Electrical Power & Mains Electricity

- Static Electricity

- Waves & The Electromagnetic Spectrum

- Reflection & Refraction

- Energy Stores & Transfers

- Work, Power & Energy Resources

- Density & Pressure

- Changes of State

- Ideal Gases

Author: Katie M

Katie has always been passionate about the sciences, and completed a degree in Astrophysics at Sheffield University. She decided that she wanted to inspire other young people, so moved to Bristol to complete a PGCE in Secondary Science. She particularly loves creating fun and absorbing materials to help students achieve their exam potential.

Something went wrong and we cannot process your request

There are a number of reasons why this might happen

The site might be down

You might have got caught by our bot protection logic

You might have tried to access a private document

To fix this you might try going back to the home page and trying again

If you still get this there, you may have either got caught by our bot protection, or the site may be down. Either way, go make a cup of warm brew, come back and try again, and it'll probably be resolved.

You might also check our twitter page

If you believe you have got this message in error, please report this citing this code

0.840c4017.1725468588.8ce74dbb

Advanced search

- Journals & magazines

- Conferences

- Collections

- Forgotten password?

Not registered yet?

- Register now to save searches and create alerts

Login to add to favourites

Save links to your favourite articles.

- Create email alert

- Get permissions

- N New content

- Free content

- Open access content

- Subscribed content

- Trial content

Electric fuses

- Author(s): P.G. Newbery and A. Wright

- DOI: 10.1049/piee.1977.0226

For access to this article, please select a purchase option:

Buy article PDF

Buy knowledge pack.

IET members benefit from discounts to all IET publications and free access to E&T Magazine. If you are an IET member, log in to your account and the discounts will automatically be applied.

Learn more about IET membership

You must fill out fields marked with: *

Your recommendation has been sent to your librarian.

- Author(s): P.G. Newbery 1 and A. Wright 2

- Affiliations: 1: Brush Fusegear Ltd., Burton on the Wolds, UK 2: Department of Electrical & Electronic Engineering, University of Nottingham, Nottingham, UK

- Source: Volume 124, Issue 11R , November 1977, p. 909 – 924 DOI: 10.1049/piee.1977.0226 , Print ISSN 0020-3270 , Online ISSN 2053-7891

- « Previous Article

- Table of contents

- Next Article »

- References (9)

- Cited By (0)

- Supplementary material (0)

- Related Content

Fuses are produced in large numbers and in a wide variety of types ranging from those capable of protecting 132 kV equipment down to the miniature versions used in electronic circuits. The review starts by tracing the development of fuses before the beginning of the 20th century and then describes the constructions of the basic types now in use. This is followed first by a consideration of the factors which affect the behaviour of fuses, and then details are given of the type-testing and quality-assurance procedures that are employed to establish performance characteristics and ensure consistency in production. The features of the different types of fuse in use today are examined under the accepted classification headings, namely ( a ) high-voltage fuses, ( b ) low-voltage fuses (including those for the protection of industrial and domestic circuits and equipment and also semiconductors) and ( c ) miniature fuses. Finally, possible developments in fuse technology are considered, to indicate how fuses may be adapted to meet changing requirements in the future.

- J.N. Pearch , P.G. Newbery . Fast acting fuses for the protection of semi-conductors. IEEE Trans. , 332 - 338

- : Papers presented at conference on electric fuses and their applications, April 1976, Liver-pool Polytechnic.

- A.C. Cockburn . On safety fuses for electric light circuits and on the behaviour of the various metals usually employed in their construction. J. Soc. of Teleg. Eng. , 650 - 665

- (1976) , Fuses:a multinational survey.

- D.R. Aubrey . 11 kV expulsion fuse field tests promising. Elec. Times

- J.G. Leach , P.G. Newbery . (1974) , Advances in development and application of semiconductor fuselinks.

- A.W. Metcalf . A new fuse phenomenon. BEAMA J.

- J.G. Leach , P.G. Newbery , A. Wright . Analysis ofhigh-rupturing-capacity fuselink prearcing phenomena by afinite-difference method. Proc. IEE , 9 , 987 - 993

- A. Wright , K.J. Beaumont . Analysis of high-breaking-capacity fuselink arcing phenomena. Proc. IEE , 3 , 252 - 260

Related content

- View sitemap

- Legal notices

- Accessibility

- Privacy statement

- Copyright & permissions

All contents © The Institution of Engineering and Technology 2024

- The Institution of Engineering and Technology is registered as a Charity in England & Wales (no 211014) and Scotland (no SC038698)

What is an electric fuse?

Step 1: Definition An electrical fuse is a low melting point copper or other metal wire that breaks due to heat caused by overvoltage or high load to avoid short circuit or failure to the device. Step 2: Functions of electric fuses A fuse is a service that delivers usable electrical circuit over-current safety. Some of the main fuse functions are as follows: Acts as a barrier between both the human body and the electric circuit. Inhibits system failure due to defective operation of circuits. Fuse avoids short-circuits. Inhibits blackouts & overloading. Prevents harm caused by mismatched loads. Therefore, a fuse is a safety device that protects electrical circuits from the effects of excessive currents.

What is an electric fuse? State its purpose in the household electrical circuit.

What is immaterial for an electric fuse?

IMAGES

VIDEO

COMMENTS

In the field of electrical engineering, a fuse is a device that provides overcurrent protection to the functional electrical circuit. Here, we have listed a few major functions of the fuse. Acts as a barrier between the electric circuit and the human body. Prevents device failure due to faulty circuit operation. Fuse prevents short-circuits.

An Electric Fuse is an Electric device which interrupts the flow of current in an Electric circuit. It is installed in a circuit to stop the flow of excessive current. A Fuse is usually a short piece of wire. The Fuse is made up of a material which has high resistivity and low melting point, so that it melts down due to overheating of the wire ...

Fuse (electrical) A miniature time-delay 250 V fuse that will interrupt a 0.3 A current at after 100 s, or a 15 A current in 0.1 s. 32 mm (1 1/4") long. In electronics and electrical engineering, a fuse is an electrical safety device that operates to provide overcurrent protection of an electrical circuit. Its essential component is a metal ...

The electrical fuse is a device used to protect a load or source from overcurrent. It is a simple, less resistive, self-sacrificial and cheap device used to interrupt a circuit from short-circuiting, excessive overload, or over-current conditions. Electrical fuses can be found everywhere, from the generating stations to small home appliances.

The latter fuses are sometimes called slow-blow fuses due to their intentional time-delay characteristics. A classic example of a slow-blow fuse application is in electric motor protection, where inrush currents of up to ten times normal operating current are commonly experienced every time the motor is started from a dead stop. If fast-blowing ...

A fuse is an electrical safety device that protects electrical circuits and electronics devices from damage caused by excessive current. It does so by melting and breaking the circuit when the current surpasses the safe limits. Fuses are available in various types and ratings, making choosing the appropriate fuse for the specific application ...

A fuse cannot protect anything that is connected in parallel with it. Fuse Design Best Practices: Rated Current vs. Operating Current. It would be perfectly reasonable to assume that a fuse rated for 6 amps could be used in a circuit that might need 5 amps of steady-state current. It turns out, though, that this is not good design practice.

The fuses described previously are all cartridge fuses, as shown in Figure 1, a cartridge fuse is the one that has a tube shaped body. A Type T Fuse has an Edison base. As shown in Figure 6a, the Edison base resembles the base of a light bulb. This type of fuse screws directly into a standard fuse socket. Figure 6: Common electrical fuses. (a ...

A fuse is an electrical safety device that protects an electric circuit from excessive electric current.Fuses are destroyed during overload conditions. When reasonable to do so (and economically sensible), circuit breakers are used instead because they are not destroyed during overload conditions. It's cheaper to install fuses than circuit breakers, but since fuses need to be replaced and ...

Home / Technical Articles / Fuses - Principles of design and operation. A fuse consists of a replaceable part (the fuselink) and a fuse holder. Examples of fuse holders are shown in Fig. 1. The simplest fuselink is a length of wire. It is mounted by screw connections in a holder which partly encloses it. When an overcurrent or short-circuit ...