Advertisement

Food Adulteration Detection using Artificial Intelligence: A Systematic Review

- Review article

- Published: 15 June 2021

- Volume 29 , pages 397–426, ( 2022 )

Cite this article

- Kashish Goyal ORCID: orcid.org/0000-0003-3827-1167 1 ,

- Parteek Kumar 1 &

- Karun Verma 1

3657 Accesses

40 Citations

Explore all metrics

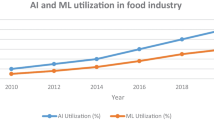

Food Adulteration is a deceptive act of misleading food buyers for economic gain. It has been a major concern due to its risk to public health, reduction of food quality or nutritional value. It is a food fraud that has incensed the food industry and has attracted the attention of the community since the last century. To ensure consumer protection against fraudulent activities, authentication of food and the detection of adulterants in various food items should be taken into consideration. Artificial Intelligence has been proved to be an advanced technology in food science and engineering. In this paper, we intend to proclaim the role of artificial intelligence in food adulteration detection in a systematic way. The potential for machine learning and deep learning in food quality has been analyzed through its applications. Various data sources that are available online to detect food quality have been discussed in this review. The different techniques used to detect food adulteration and the parameters considered while evaluating the food quality have been highlighted. The various comparisons have been done among the state-of-the-art methods along with their datasets sets and results. This study will assist the researchers in analyzing the best method available to detect food quality. It will help them in finding the food products that are studied by different researchers along with relevant future research directions.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Artificial Intelligence and Deep Learning-Based Agri and Food Quality and Safety Detection System

Applications of Artificial Intelligence and Machine Learning in Food Quality Control and Safety Assessment

Utilizing Big Data as Analytical Tool for Food Safety Applications

Explore related subjects.

- Artificial Intelligence

Availability of Data and Material

The relevant links are provided in the manuscripts.

Zhou C, Tan S, Li J, Chu X, Cai K (2014) A novel method to stabilize meat colour: ligand coordinating with hemin. J Food Sci Technol 51:1213–1217

Google Scholar

Dixit S, Khanna SK, Das M (2013) All India survey for analyses of colors in sweets and savories: exposure risk in Indian population. J Food Sci 78:642–647

Stevens LJ, Burgess JR, Stochelski MA, Kuczek T (2015) Amounts of artificial food dyes and added sugars in foods and sweets commonly consumed by children. Clin Pediatr (Phila) 54(4):309–321

Ates E, Mittendorf K, Senyuva H (2011) LC/MS method using cloud point extraction for the determination of permitted and illegal food colors in liquid, semiliquid, and solid food matrixes: single-laboratory validation. J AOAC Int 94:1853–1862

Boga A, Binokay S (2010) Food additives and effects to human health. Arch Med Rev J 19:141–154

Fik M, Surówka K, Firek B (2008) Properties of refrigerated ground beef treated with potassium lactate and sodium diacetate. J Sci Food Agric 88:91–99

Uzan A, Delaveau P (2009) The salt content of food: a public health problem. Ann Pharm Fr 67:291–294

Tian H, Li F, Qin L, Yu H, Ma X (2014) Discrimination of chicken seasonings and beef seasonings using electronic nose and sensory evaluation. J Food Sci 79(11):2346–2353. https://doi.org/10.1111/1750-3841.12675

Article Google Scholar

Brosnan T, Sun DW (2004) Improving quality inspection of food products by computer vision—a review. J Food Eng 61(1):3–16. https://doi.org/10.1016/s0260-8774(03)00183-3

Barbin DF, Felicio A, Sun DW, Nixdorf SL, Hirooka EY (2014) Application of infrared spectral techniques on quality and compositional attributes of coffee: an overview. Food Res Int 61:23–32. https://doi.org/10.1016/j.foodres.2014.01.005

Jia W, Li Y, Qu R, Baranowski T, Burke LE, Zhang H, Mao ZH (2018) Automatic food detection in egocentric images using artificial intelligence technology. Public Health Nutr 22(7):1168–1179. https://doi.org/10.1017/S1368980018000538

Pouladzadeh P, Villalobos G, Almaghrabi R, Shirmohammadi S (2012) A novel SVM based food recognition method for calorie measurement applications. In: 2012 IEEE international conference on multimedia and expo workshops, pp 495–498. https://doi.org/10.1109/ICMEW.2012.92

Bossard L, Guillaumin M, Gool LV (2014) Food-101-Mining discriminative components with random forests. In: Fleet D, Pajdla T, Schiele B, Tuytelaars T (eds) Computer vision—ECCV 2014, Pt Vi, vol 8694, pp 446–461. https://doi.org/10.1007/978-3-319-10599-4_29

Yordi EG, Koelig R, Mota YC, Matos MJ, Santana L, Uriarte E, Molina E (2015) Application of KNN algorithm in determining the total antioxidant capacity of flavonoid-containing foods. In: 19th international electronic conference on synthetic organic chemistry. https://doi.org/10.3390/ecsoc-19-e002

Granato D, Santos JS, Escher GB, Ferreira BL, Maggio RM (2018) Use of principal component analysis (PCA) and hierarchical cluster analysis (HCA) for multivariate association between bioactive compounds and functional properties in foods: a critical perspective. Trends Food Sci Technol 72:83–90. https://doi.org/10.1016/j.tifs.2017.12.006

Ma B-Q (2017) Food packaging printing defect detection method based on image wavelet transform. Food Res Dev 38(5):212–215. https://doi.org/10.3969/j.issn.1005-6521.2017.05.046

Monakhova YB, Tsikin AM, Kuballa T, Lachenmeier DW, Mushtakova SP (2014) Independent component analysis (ICA) algorithms for improved spectral deconvolution of overlapped signals in H-1 NMR analysis: application to foods and related products. Magn Reson Chem 52(5):231–240. https://doi.org/10.1002/mrc.4059

Giovany S, Putra A, Hariawan AS, Wulandhari LA (2017) Machine learning and SIFT approach for Indonesian food image recognition. Discov Innov Comput Sci Technol Artif Intell Era 116:612–620. https://doi.org/10.1016/j.procs.2017.10.020

Ahmed A, Ozeki T (2015) Food image recognition by using Bag-of-SURF features and HOG Features. In: Proceedings of the 3rd international conference on human-agent interaction, pp 179–180. https://doi.org/10.1145/2814940.2814968

Bansal S, Singh A, Mangal M, Mangal AK, Kumar S (2017) Food adulteration: sources, health risks, and detection methods. Crit Rev Food Sci Nutr 57(6):1174–1189

Banerjee D, Chowdhary S, Chakraborty S, Bhattacharyya R Recent advances in detection of food adulteration. In: Food safety in the 21st century 2017 Jan 1, pp 145–160. Academic Press

Bhargava A, Bansal A (2018) Fruits and vegetables quality evaluation using computer vision: a review. J King Saud Univ-Comput Inf Sci 33(3):243–247. https://doi.org/10.1016/j.jksuci.2018.06.002

Zhou L, Zhang C, Liu F, Qiu Z, He Y (2019) Application of deep learning in food: a review. Compr Rev Food Sci Food Saf 18(6):1793–1811

Heravi EJ, Aghdam HH, Puig D (2018) An optimized convolutional neural network with bottleneck and spatial pyramid pooling layers for classification of foods. Pattern Recogn Lett 105:50–58. https://doi.org/10.1016/j.patrec.2017.12.007

Yanai K, Kawano Y (2015) Food image recognition using deep convolutional network with pre-training and fine-tuning. In 2015 IEEE international conference on multimedia & expo workshops, pp 1–6. https://doi.org/10.1109/ICMEW.2015.7169816

Wu H, Merler M, Uceda-Sosa R, Smith JR (2016) Learning to make better mistakes: semantics-aware visual food recognition. In: Proceedings of the 24th ACM international conference on multimedia, pp 172–176. https://doi.org/ https://doi.org/10.1145/2964284.2967205

Pandey P, Deepthi A, Mandal B, Puhan NB (2017) FoodNet: Recognizing foods using ensemble of deep networks. IEEE Signal Process Lett 24(12):1758–1762. https://doi.org/10.1109/lsp.2017.2758862

Liu C, Cao Y, Luo Y, Chen GL, Vokkarane V, Ma YS (2016a) DeepFood: deep learning-based food image recognition for computer-aided dietary assessment. In: Chang CK, Chiari L, Cao Y, Jin H, Mokhtari M, Aloulou H (eds) Inclusive smart cities and digital health, vol 9677, pp 37–48. https://doi.org/10.1007/978-3-319-39601-9_4

Liu C, Cao Y, Luo Y, Chen G, Vokkarane V, Ma Y, Hou P (2018) A new deep learning-based food recognition system for dietary assessment on an edge computing service infrastructure. IEEE Trans Serv Comput 11(2):249–261. https://doi.org/10.1109/tsc.2017.2662008

Fu ZH, Chen D, Li HY (2017) ChinFood1000: a large benchmark dataset for Chinese food recognition. In: Huang DS, Bevilacqua V, Premaratne P, Gupta P (eds) Intelligent computing theories and application, ICIC 2017, Pt I, vol 10361, pp 273–281. https://doi.org/10.1007/978-3-319-63309-1_25

Ciocca G, Napoletano P, Schettini R (2018) CNN-based features for retrieval and classification of food images. Comput Vis Image Underst 176:70–77. https://doi.org/10.1016/j.cviu.2018.09.001

Zheng J, Zou L, Wang ZJ (2018) Mid-level deep food part mining for food image recognition. IET Comput Vis 12(3):298–304. https://doi.org/10.1049/iet-cvi.2016.0335

Hassannejad H, Matrella G, Ciampolini P, De Munari I, Mordonini M, Cagnoni S (2016) Food image recognition using very deep convolutional networks. In Proceedings of the 2nd international workshop on multimedia assisted dietary management, pp 41–49. https://doi.org/10.1145/2986035.2986042

Martinel N, Foresti TL, Micheloni C (2018) Wide-slice residual networks for food recognition. In: 2018 IEEE winter conference on applications of computer vision, pp 567–576. https://doi.org/10.1109/WACV.2018.00068

Kawano Y, Yanai K (2014) Food image recognition with deep convolutional features. In: Proceedings of the 2014 ACM international joint conference on pervasive and ubiquitous computing: adjunct publication, pp 589–593. https://doi.org/10.1145/2638728.2641339

Chen JJ, Ngo CW (2016) Deep-based ingredient recognition for cooking recipe retrieval. In: Proceedings of the 24th ACM international conference on multimedia, pp 32–41. https://doi.org/10.1145/2964284.2964315

Chung DT, Van Tai D (2019) A fruits recognition system based on a modern deep learning technique. In: Journal of physics: conference series, vol 1327, no 1, p 012050. IOP Publishing

Sakib S, Ashrafi Z, Siddique M, Bakr A (2019) Implementation of fruits recognition classifier using convolutional neural network algorithm for observation of accuracies for various hidden layers. arXiv:1904.00783

Hussain I, He Q, Chen Z (2018) Automatic fruit recognition based on dcnn for commercial source trace system. Int J Comput Sci Appl (IJCSA). https://doi.org/10.5121/ijcsa.2018.8301

Sun X, Ma L, Li G (2019) Multi-vision attention networks for on-line red jujube grading. Chin J Electron 28(6):1108–1117

McAllister P, Zheng H, Bond R, Moorhead A (2018) Combining deep residual neural network features with supervised machine learning algorithms to classify diverse food image datasets. Comput Biol Med 1(95):217–233

Şengür A, Akbulut Y, Budak Ü (2019) Food image classification with deep features. In: 2019 international artificial intelligence and data processing symposium (IDAP), pp 1–6. IEEE

http://vikaspedia.in/health/health-campaigns/beware-of-adulteration/adulteration-in-milk-and-milk-products

https://www.google.com/imgres?imgurl=https%3A%2F%2Fqph.fs.quoracdn.net%2Fmain-qimg-6804e0d932c0b213a5c065f423303ae6&imgrefurl=https%3A%2F%2Fwww.quora.com%2FWhat-is-food-scanner-technology-and-who-are-its-key-players&tbnid=1HRjP9qlufPVHM&vet=1&docid=PU7Cl0QuOmyAmM&w=529&h=408&q=smartphone&hl=en-IN&source=sh%2Fx%2Fim

Pourreza A, Pourreza H, Abbaspour-Fard M-H, Sadrnia H (2012) Identification of nine Iranian wheat seed varieties by textural analysis with image processing. Comput Electron Agric 83:102–108

Neelamegam P, Abirami S, Priya KV, Valantina SR (2013) Analysis of rice granules using image processing and neural network. In: 2013 IEEE conference on information & communication technologies, pp 879–884. IEEE.

Nandi CS, Tudu B, Koley C. Computer vision based mango fruit grading system. InInternational Conference on Innovative Engineering Technologies (ICIET 2014) Dec 2014 Dec 28 (pp. 28–29).

Carolina CPD, Nieto TDD (2014) Classification of oranges by maturity, using image processing techniques. In: 2014 III international congress of engineering mechatronics and automation (CIIMA), pp 1–5. IEEE

Ropodi AI, Pavlidis DE, Mohareb F, Panagou EZ, Nychas GJ (2015) Multispectral image analysis approach to detect adulteration of beef and pork in raw meats. Food Res Int 1(67):12–18

Khosa I, Eros P (2014) Defect detection in food ingredients using multilayer perceptron neural network. In: 2014 world symposium on computer applications & research (WSCAR), pp 1–5. IEEE

Kamruzzaman M, Makino Y, Oshita S (2016) Rapid and non-destructive detection of chicken adulteration in minced pork using visible near-infrared hyperspectral imaging and machine learning. J Food Eng 170:8–15

Ali T, Zeeshan J, Awais A, Murad K, Arif AK, Gyu SC (2017) Detecting fraudulent labeling of rice samples using computer vision and fuzzy knowledge. Multimed Tools Appl 76(23):24675–24704

Lim DK, Nguyen PL, Changyeun M, Ziyuan D, Lingmei C, Giyoung K, Sung WK (2017) Combination of mass spectrometry-based targeted lipidomics and supervised machine learning algorithms in detecting adulterated admixtures of white rice. Food Res Int 100:814–821

Kobek JA (2017) Vision based model for identification of adulterants in milk. PhD diss., Strathmore University

Fayyazi S, Mohammad HA-F, Abbas R, Amirhassan Monadjemi S, Hassan Sadrnia () Identification and classification of three iranian rice varieties in mixed bulks using image processing and MLP neural network. Int J Food Eng 13(5)

Rong D, Rao X, Ying Y (2017) Computer vision detection of surface defect on oranges by means of a sliding comparison window local segmentation algorithm. Comput Electron Agric 137:59–68. https://doi.org/10.1016/j.compag.2017.02.027

Anami BS, Malvade NN, Palaiah S (2019) Automated recognition and classification of adulteration levels from bulk paddy grain samples. Inf Process Agricult 6(1):47–60

Tripathy S, Manne SR, Siva RKV, Soumya J, Shiv GS (2019) A step towards miniaturized milk adulteration detection system: smartphone-based accurate pH sensing using electrospun halochromic nanofibers. Food Anal Methods 12(2):612–624

Al-Sarayreh M, Marlon MR, Wei QY, Reinhard K (2018) Detection of red-meat adulteration by deep spectral–spatial features in hyperspectral images. J Imag 4(5):63

Neto HA, Wanessa LFT, Daniela CSZR, Ronnie COA, Leorges MF, Sérgio VAC (2019) On the utilization of deep and ensemble learning to detect milk adulteration. BioData Min 12(1):1–13

Izquierdo M, Lastra-Mejías M, González-Flores E, Pradana-López S, Cancilla JC, Torrecilla JS (2020) Visible imaging to convolutionally discern and authenticate varieties of rice and their derived flours. Food Control 1(110):106971

Li C, Gitaitis R, Tollner B, Sumner P, MacLean D (2009) Onion sour skin detection using a gas sensor array and support vector machine. Sens Instrum Food Qual Saf 3(4):193

Dębska B, Guzowska-Świder B (2011) Application of artificial neural network in food classification. Anal Chim Acta 705(1–2):283–291

Gómez-Meire S, Campos C, Falqué E, Díaz F, Fdez-Riverola F (2014) Assuring the authenticity of northwest Spain white wine varieties using machine learning techniques. Food Res Int 60:230–240

Bandyopadhyaya I, Babu D, Bhattacharjee S, Roychowdhury J (2014) Vegetable grading using tactile sensing and machine learning. In: Advanced computing, networking and informatics-volume 1, pp 77–85. Springer, Cham

Peng D, Bi Y, Ren X, Yang G, Sun S, Wang X (2015) Detection and quantification of adulteration of sesame oils with vegetable oils using gas chromatography and multivariate data analysis. Food Chem 188:415–421

Mu T, Chen S, Zhang Y, Chen He, Guo P, Meng F (2016) Portable detection and quantification of olive oil adulteration by 473-nm laser-induced fluorescence. Food Anal Methods 9(1):275–279

Rashvand M, Mahmoud O, Hossein M, Mahmoud SF (2016) Adulteration detection in olive oil using dielectric technique and data mining. Sens Bio-Sens Res 11:33–36

Yu J, Zhan J, Huang W (2017) Identification of wine according to grape variety using near-infrared spectroscopy based on radial basis function neural networks and least-squares support vector machines. Food Anal Methods 10(10):3306–3311

Zhang R, Zhou L, Zuo M, Zhang Q, Bi M, Jin Q, Xu Z (2018) Prediction of dairy product quality risk based on extreme learning machine. In: 2018 2nd international conference on data science and business analytics (ICDSBA), pp 448–456. IEEE

de Santana FB, Neto WB, Poppi RJ (2019) Random forest as one-class classifier and infrared spectroscopy for food adulteration detection. Food Chem 30(293):323–332

Naskar H, Nandeshwar V, Das S (2018) Adulteration detection of grape fruit juice using PCA and LDA pattern recognition technique. In: 2018 IEEE applied signal processing conference (ASPCON) Dec 7, pp 83–86. IEEE

Jia B, Yang Y (2011) The design of food quality supervision platform based on the Internet of Things. In: Proceedings 2011 international conference on transportation, mechanical, and electrical engineering (TMEE), pp 263–266. IEEE

Eom KH, Kim MC, Lee S, Lee CW (2012) The vegetable freshness monitoring system using RFID with oxygen and carbon dioxide sensor. Int J Distrib Sens Netw 8(6):472986

Chanthini B, Manivannan D, Umamakeswari A (2017) Perishable food quality monitoring–an internet of things (IoT) Approach” ISSN: 1311–8080 (printed version); ISSN: 1314–3395 (on-line version)

Gupta K, Nitin R (2018) IoT-based solution for food adulteration. In: Proceedings of first international conference on smart system, innovations and computing , pp 9–18. Springer, Singapore

Kang H, Chen C (2019) Fruit detection and segmentation for apple harvesting using visual sensor in orchards. Sensors 19(20):4599. https://doi.org/10.3390/s19204599

Roy RB, Bipan T, Rajib B, Nabarun B (2019) Application of electronic nose and tongue for beverage quality evaluation. In: Engineering tools in the beverage industry, pp 229–254. Woodhead Publishing

https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/electronic-tongue

Markom MA, Md Shakaff AY, Adom AH, Ahmad MN, Wahyu H, Abdullah AH, Ahmad Fikri N (2009) Intelligent electronic nose system for basal stem rot disease detection. Comput Electron Agric 66(2):140–146

Kundu PK, Panchariya PC, Madhusree K (2011) Classification and authentication of unknown water samples using machine learning algorithms. ISA Trans 50(3):487–495

Subari N, Junita MS, Ali MdS, Ammar Z (2012) A hybrid sensing approach for pure and adulterated honey classification. Sensors 12(10):14022–14040

Teye E, Huang X, Han F, Botchway F (2014) Discrimination of cocoa beans according to geographical origin by electronic tongue and multivariate algorithms. Food Anal Methods 7(2):360–365

Tian X, Jun W, Zhongren M, Mingsheng L, Zhenbo W (2019) Combination of an E-Nose and an E-tongue for adulteration detection of minced mutton mixed with pork. J Food Qual 2019

Heidarbeigi K, Seyed SM, Amin F, Mahdi G-V, Shahin R, Karamatollah R (2015) Detection of adulteration in saffron samples using electronic nose. Int J Food Propert 18(7):1391–1401. https://doi.org/10.1080/10942912.2014.915850

Bougrini M, Khalid T, Tarik S, El Alami N, El H, Benachir B, El Bari N (2016) Classification of honey according to geographical and botanical origins and detection of its adulteration using voltammetric electronic tongue. Food Anal Methods 9(8):2161–2173

Ordukaya E, Bekir K (2017) Quality control of olive oils using machine learning and electronic nose. J Food Qual 2017

Ayari F, Mirzaee-Ghaleh E, Rabbani H, Heidarbeigi K (2018) Detection of the adulteration in pure cow ghee by electronic nose method (case study: sunflower oil and cow body fat). Int J Food Prop 21(1):1670–1679. https://doi.org/10.1080/10942912.2018.1505755

Krizhevsky A, Sutskever I, Hinton GE (2012) ImageNet classification with deep convolutional neural networks. In: Proceedings of the 25th international conference on neural information processing systems, pp 1097–1105

Simonyan K, Zisserman A (2014) Very deep convolutional networks for large-scale image recognition. Retrieved from http://arxiv.org/abs/1409.1556

Szegedy C, Liu W, Jia YQ, Sermanet P, Reed S, Anguelov D, Rabinovich A (2015) Going deeper with convolutions. In: 2015 IEEE conference on computer vision and pattern recognition, pp 1–9. https://doi.org/10.1109/CVPR.2015.7298594

He KM, Zhang XY, Ren SQ, Sun J (2016) Deep residual learning for image recognition. In: 2016 IEEE conference on computer vision and pattern recognition, pp 770–778. https://doi.org/10.1109/CVPR.2016.90

Deng J, Dong W, Socher R, Li LJ, Li K, Li FF (2009) ImageNet: a large-scale hierarchical image database. In: 2009 IEEE conference on computer vision and pattern recognition, Miami, FL, pp 248–255. https://doi.org/10.1109/CVPR.2009.5206848

Rocha A, Hauagge DC, Wainer J, Goldenstein S (2010) Automatic fruit and vegetable classification from images. Comput Electron Agric 70(1):96–104

Khaing ZM, Naung Y, Htut PH (2018) Development of control system for fruit classification based on convolutional neural network. In: 2018 IEEE conference of russian young researchers in electrical and electronic engineering (EIConRus), pp 1805–1807. IEEE.

Ragusa F, Tomaselli V, Furnari A, Battiato S, Farinella GM (2016) Food vs non-food classification. In: Proceedings of the 2nd international workshop on multimedia assisted dietary management, pp 77–81. https://doi.org/10.1145/2986035.2986041

Shimoda W, Yanai K (2015) CNN-based food image segmentation without pixel-wise annotation. In: International conference on image analysis and processing. Springer, Cham, pp 449–457

Tatsuma A, Aono M (2016) Food image recognition using covariance of convolutional layer feature maps. IEICE Trans Inf Syst E99D(6):1711–1715. https://doi.org/10.1587/transinf.2015EDL8212

Mezgec S, Seljak BK (2017) NutriNet: a deep learning food and drink image recognition system for dietary assessment. Nutrients. https://doi.org/10.3390/nu9070657

Herruzo P, Bola˜nos M, Radeva P (2016) Can a cnn recognize Catalan diet? In: AIP conference proceedings, vol 1773. https://doi.org/10.1063/1.4964956

Myers A, Johnston N, Rathod V, Korattikara A, Gorban A, Silberman N, Murphy K (2015) Im2Calories: towards an automated mobile vision food diary. In: 2015 IEEE international conference on computer vision, pp 1233–1241. https://doi.org/ https://doi.org/10.1109/ICCV.2015.146

Ege T, Yanai K (2018) Image-based food calorie estimation using recipe information. IEICE Trans Inf Syst E 101D(5):1333–1341. https://doi.org/10.1587/transinf.2017MVP0027

Mao DH, Wang F, Hao ZH, Li HS (2018) Credit evaluation system based on blockchain for multiple stakeholders in the food supply chain. Int J Environ Res Public Health 15(8):21. https://doi.org/10.3390/ijerph15081627

Kim Y (2014) Convolutional neural networks for sentence classification. In: Proceedings of the 2014 conference on empirical methods in natural language processing, pp 1746–1751. https://doi.org/10.3115/v1/D14-1181

Liu Z, He Y, Cen H, Lu R (2018) Deep feature representation with stacked sparse auto-encoder and convolutional neural network for hyperspectral imaging-based detection of cucumber defects. Trans ASABE 61(2):425–436. https://doi.org/10.13031/trans.12214

Mustafa NBA, Kumutha A, Syed KA, Zainul AMS (2011) Classification of fruits using probabilistic neural networks-improvement using color features. In: TENCON 2011–2011 IEEE region 10 conference, pp 264–269. IEEE

Jhuria M, Ashwani K, Rushikesh B (2013) Image processing for smart farming: detection of disease and fruit grading. In: 2013 IEEE second international conference on image information processing (ICIIP-2013), pp 521–526. IEEE

Moallem P, Serajoddin A, Pourghassem H (2017) Computer vision-based apple grading for golden delicious apples based on surface features. Inf Process Agricult 4(1):33–40

Sahu D, Ravindra MP (2017) Defect identification and maturity detection of mango fruits using image analysis. Am J Artif Intell 1(1):5–14

Rodriguez FJ, Garcia A, Pardo PJ, Chavez F, Luque-Baena RM (2018) Study and classification of plum varieties using image analysis and deep learning techniques. Progress Artif Intell 7(2):119–127. https://doi.org/10.1007/s13748-017-0137-1

Azizah LM, Umayah SF, Riyadi S, Damarjati C, Utama NA (2017) Deep learning implementation using convolutional neural network in mangosteen surface defect detection. In: 2017 7th IEEE international conference on control system, computing and engineering (ICCSCE), pp 242–246. https://doi.org/10.1109/ICCSCE.2017.8284412

Tan WX, Zhao CJ, Wu HR (2016) Intelligent alerting for fruit-melon lesion image based on momentum deep learning. Multimed Tools Appl 75(24):16741–16761. https://doi.org/10.1007/s11042-015-2940-7

Mithun BS, Shinde S, Bhavsar K, Chowdhury A, Mukhopadhyay S, Gupta K, Kimbahune S (2018) Non-destructive method to detect artificially ripened banana using hyperspectral sensing and RGB imaging. In: Kim MS, Chao K, Chin BA, Cho BK (eds) Sensing for agriculture and food quality and safety X, vol 10665. https://doi.org/10.1117/12.2306367

Sun Y, Wei KL, Liu Q, Pan LQ, Tu K (2018) Classification and discrimination of different fungal diseases of three infection levels on peaches using hyperspectral reflectance imaging analysis. Sensors 18:4. https://doi.org/10.3390/s18041295

Lukinac J, Jukić M, Mastanjević K, Lučan M (2018) Application of computer vision and image analysis method in cheese-quality evaluation: a review. Ukr Food J 7(Issue2):192–214

Ali MAH, Thai KW (2017) Automated fruit grading system. Int Symp Rob Manufact Autom, 1–6

Nandi CS, Tudu B, Koley C (2016) A Machine vision technique for grading of harvested mangoes based on maturity and quality. IEEE Sens J 16:6387–6396. https://doi.org/10.1109/JSEN.2016.2580221

Li JB, Rao XQ, Ying YB (2011) Detection of common defects on oranges using hyperspectral reflectance imaging. Comput Electron Agric 78(1):38–48

Hu M, Dong Q, Liu B, Malakar PK (2013) The potential of double K-means clustering for banana image segmentation. J. Food Process Eng 37 (1), 10–18. InkyuSa et al., 2016. Deep fruits: a fruit detection system using deep neural networks. Sensors 16:1222–1228

Arakeria MP, Lakshmana (2016) Computer vision based fruit grading system for quality evaluation of tomato in agriculture industry. In: International conference on communication, computing and virtualization, 426–433

Mehra T, Kumar V, Gupta P (2016) Maturity and disease detection in tomatousing computer vision. In: Fourth International Conference on Parallel, Distributed and Grid Computing (PDGC), pp 399–403. https://doi.org/10.1109/PDGC.2016.7913228

Blasco J, Cubero S, Gomez-Sanchis J, Mira P, Molto E (2009) Development of a machine for the automatic sorting of pomegranate (Punica granatum) arilsbased on computer vision. J Food Eng 90(1):27–34

Liming X, Yanchao Z (2010) Automated strawberry grading system based on image processing. Comput Electron Agric 71:32–39

Dorj UO, Lee M, Yum S (2017) An yield estimation in citrus orchards via fruit detection and counting using image processing. Comput Electron Agric 140:103–112

Vidal A, Talens P, Prats-Montalbán J, Cubero S, Albert F, Blasco J (2013) In-line estimation of the standard colour index of citrus fruits using a computer vision system developed for a mobile platform. Food Bioprocess Technol 6(12):3412–3419

Wang Y, Zhang M, Mujumdar AS (2012) Influence of green banana flour substitution for cassava starch on the nutrition, color, texture and sensory quality in two types of snacks. Food Sci Technol 47(1):175–182

Prabha DS, Kumar JS (2013) Assessment of banana fruit maturity by image processing technique. J Food Sci Technol

Yahaya OKM, MatJafri MZ, Aziz AA, Omar AF (2014) Non-destructive quality evaluation of fruit by color based on RGB LEDs system. In: 2014 2nd International Conference on Electronic Design (ICED), pp. 230–233. https://doi.org/10.1109/ICED.2014.7015804

Xiao-bo Z, Jie-wen Z, Yanxiao L, Holmes M (2010) In-line detection of apple defects using three color cameras system. Comput Electron Agric 70(1):129–134. https://doi.org/10.1016/j.compag.2009.09.014

Garrido-Novell C, Perez-Marin D, Amigo JM, Fernandez-Novales J, Guerrero JE, Garrido-Varo A (2012) Grading and color evolution of apples using RGB and hyperspectral imaging vision cameras. J Food Eng 113(2):281–288

Singh Chauhan AP, Pratap Singh A (2012) Intelligent estimator for assessing apple fruit quality. Int J Comput Appl 60:35–41

Suresha M, Shilpa NA, Saumya B (2012a) Apple grading based on SVM Classifier. Int J Comput Appl, 27–30

Stefany CP, Jorge CP, Juan VMM, Georgina CD, Ruben LS, Marıa JPF, Israel AV (2017) Evaluation of the ripening stages of apple (Golden Delicious) by means of computer vision system. Biosyst Eng 159:46–58

Esehaghbeygi A, Ardforoushan M, Monajemi SAH, Masoumi AA (2010) Digital image processing for quality ranking of saffron peach. Int Agrophys 24(2):115–120

Pereira LFS Jr, Valous NA, Barbin DF (2018) Predicting the ripening of papaya fruit with digital imaging and random forests. Comput Electron Agricult 145:76–82

Zhang C, Chen L, Huang W, Guo Z, Wang Q (2012) Apple stem-end/calyx identification using a speckle-array encoding pattern. ICSP Proc., pp. 1110–1114

Ashok V, Vinod DS (2014) Automatic quality evaluation of fruits using probabilistic neural network approach. In: International conference on contemporary computing and informatics (IC3I) IEEE, pp 308–311.

Zhang YD, Wu LN (2012) Classification of fruits using computer vision and a multiclass support vector machine. Sensors 12(9):12489–12505

Kondo N (2009) Robotization in fruit grading system. Sens Instrum Food Qual Saf 3(1):81–87

Ohali AY (2011) Computer vision based date fruit grading system: Design and implementation. J King Saud Univ Comput Inf Sci 23(1):29–36

Yimyam P, Clark AF (2012) Agricultural produce grading by computer vision using Genetic Programming. Robtics Biomimetics 458–463

Khoje S, Bodhe S (2012) Performance comparison of fourier transform and its derivatives as shape descriptors for mango grading. Int J Comput Appl 53:17–22

ElMasry G, Cubero S, Molto E, Blasco J (2012) In-line sorting of irregular potatoes by using automated computer-based machine vision system. J Food Eng 112(1–2):60–68

Dimatira JBU, Dadiios EP, Culibrina F, Magsumbol JA, Cruz JD, Sumage K, Tan MT, Gomez M, (2016) Application of fuzzy logic in recognition of tomato fruit maturity in smart farming. In: IEEE region 10 conference (TENCON), 2031–2035

Zhang B, Huang Z, Li J, Zhao C, Fan S, Wu J, Liu C (2014a) Principle, developments and applications of computer vision for external quality inspection of fruits and vegetables: a review. Food Res Int, 326–343

Zhang BH, Huang WQ, Li JB, Zhao CJ, Liu CL, Huang DF (2014b) Research of in-line sorting of irregular potatoes based on I-RELIEF and SVM method. J Jilin Univ Eng Technol Ed

Zhang BH, Huang WQ, Li JB, Zhao CJ, Liu CL, Huang DF (2014) Detection of slight bruises on apples based on hyperspectral imaging and MNF transform. Spectrosc Spectral Anal 34(5):1367–1372. https://doi.org/10.3964/j.issn.1000-0593(2014)05-1367-06

Zhang Y, Wang S, Ji G, Philiips P (2014d) Fruit Classification using computervision and feedforward neural network. J Food Eng, 167–177

Li D, Shen M, Li D, Yu X (2017) Green apple recognition method based on combination of texture and shape features. In IEEE International Conference on Mechatronics and Automation (ICMA), pp 264–269. https://doi.org/10.1109/ICMA.2017.8015825

Jana S, Basak S, Parekh R (2017) Automatic fruit recognition from natural images using color and texture features. Device Integr Circuits, 620–624

Pan Y, Liu L, Yang L, Wang Y (2016) Texture feature extracting method based on local relative phase binary pattern. In: 5th international conference on computer science and network technology (ICCSNT), pp 749–753. https://doi.org/10.1109/ICCSNT.2016.8070258

Deepa P, Geethalakshmi SN (2012) A comparative analysis of watershed and color based segmentation for fruit grading. Int J Soft Comput Eng (IJSCE) 2(3):11–15

Savakar D (2012) Identification and classification of bulk fruits images using artificial neural networks. Int J Eng Innov Technol 1(3):36–40

Khoje SA, Bodhe SK, Adsul A (2013) Automated skin defect identification system for fruit grading based on discrete curvelet transform. Int J Eng Technol 5(4):3251–3256

Khoje SA, Bodhe SK, Adsul A (2013) Automated skin defect identification system for fruit grading based on discrete curvelet transform. Int J Eng Technol 5:3251–3256

Nozari V, Mazlomzadeh M (2013) Date grading based on some physical properties. J Agric Technol 9(7):1703–1713

Alavi N (2012) Date grading using rule based fuzzy inference system. J Agric Technol 8:1243–1254

Pourjafar M, Benam MR, Mazloumzadeh SM (2013) Using adaptive neuro-fuzzy interference system for classify date fruits. J Agric Technol 9(5):1309–1318

Khojastehnazhand M, Omid M, Tabatabaeefar A (2010) Development of lemon sorting system based on color and size. Afr J Plant Sci 4(4):122–127

Razak TRB, Othman MB, Bakar MNBA, Ahmad KAB, Mansor AB (2012) Mango grading by using fuzzy image analysis in international conference on agricultural. Environ Biol Sci 18–22

Sahu D, Potdar RM (2017) Defect identification and maturity detection of mango fruits using image analysis. Am J Artif Intell 1(1):5–14

Naik S, Patel B (2017b) Thermal imaging with fuzzy classifier for maturity and size based non-destructive Mango ( Mangifera Indica L.) grading. In: International Conference on Emerging Trends & Innovation in ICT, pp 15–20. https://doi.org/10.1109/ETIICT.2017.7977003.

https://www.tribuneindia.com/news/haryana/ndri-develops-kit-to-detect-adulteration-in-milk/417546.html

http://www.myfoodsniffer.com/

Mahato K, Chandra P (2019) based miniaturized immunosensor for naked eye ALP detection based on digital image colorimetry integrated with smartphone. Biosens Bioelectron 128:9–16

Download references

Acknowledgements

This work was supported by Thapar-TAU Center for Excellence in Food Security (T2CEFS), under research project “A Data-Driven Approach to Precision Agriculture in Small Farms Project”.

Not Applicable.

Author information

Authors and affiliations.

Computer Science and Engineering Department, Thapar Institute of Engineering and Technology, Patiala, 147004, India

Kashish Goyal, Parteek Kumar & Karun Verma

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Kashish Goyal .

Ethics declarations

Conflict of interest.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (PPTX 973 kb)

Rights and permissions.

Reprints and permissions

About this article

Goyal, K., Kumar, P. & Verma, K. Food Adulteration Detection using Artificial Intelligence: A Systematic Review. Arch Computat Methods Eng 29 , 397–426 (2022). https://doi.org/10.1007/s11831-021-09600-y

Download citation

Received : 15 September 2020

Accepted : 27 April 2021

Published : 15 June 2021

Issue Date : January 2022

DOI : https://doi.org/10.1007/s11831-021-09600-y

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Find a journal

- Publish with us

- Track your research

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- My Bibliography

- Collections

- Citation manager

Save citation to file

Email citation, add to collections.

- Create a new collection

- Add to an existing collection

Add to My Bibliography

Your saved search, create a file for external citation management software, your rss feed.

- Search in PubMed

- Search in NLM Catalog

- Add to Search

Food adulteration: Sources, health risks, and detection methods

Affiliations.

- 1 a Central Institute of Post Harvest Engineering and Technology , Ludhiana , Punjab , India.

- 2 b Indian Agricultural Research Institute , New Delhi , India.

- 3 c Central Council for Research in Ayurvedic Sciences , New Delhi , India.

- 4 d National Medicinal Plant Board , New Delhi , India.

- PMID: 26054861

- DOI: 10.1080/10408398.2014.967834

Adulteration in food has been a concern since the beginning of civilization, as it not only decreases the quality of food products but also results in a number of ill effects on health. Authentic testing of food and adulterant detection of various food products is required for value assessment and to assure consumer protection against fraudulent activities. Through this review we intend to compile different types of adulterations made in different food items, the health risks imposed by these adulterants and detection methods available for them. Concerns about food safety and regulation have ensured the development of various techniques like physical, biochemical/immunological and molecular techniques, for adulterant detection in food. Molecular methods are more preferable when it comes to detection of biological adulterants in food, although physical and biochemical techniques are preferable for detection of other adulterants in food.

Keywords: Food; adulterants; adulteration; detection methods; food safety.

PubMed Disclaimer

Similar articles

- Development of a Hazard Classification Scheme for Substances Used in the Fraudulent Adulteration of Foods. Everstine K, Abt E, McColl D, Popping B, Morrison-Rowe S, Lane RW, Scimeca J, Winter C, Ebert A, Moore JC, Chin HB. Everstine K, et al. J Food Prot. 2018 Jan;81(1):31-36. doi: 10.4315/0362-028X.JFP-17-173. J Food Prot. 2018. PMID: 29257723

- Recent advances on determination of milk adulterants. Nascimento CF, Santos PM, Pereira-Filho ER, Rocha FRP. Nascimento CF, et al. Food Chem. 2017 Apr 15;221:1232-1244. doi: 10.1016/j.foodchem.2016.11.034. Epub 2016 Nov 9. Food Chem. 2017. PMID: 27979084 Review.

- Calibration and testing of a Raman hyperspectral imaging system to reveal powdered food adulteration. Lohumi S, Lee H, Kim MS, Qin J, Kandpal LM, Bae H, Rahman A, Cho BK. Lohumi S, et al. PLoS One. 2018 Apr 30;13(4):e0195253. doi: 10.1371/journal.pone.0195253. eCollection 2018. PLoS One. 2018. PMID: 29708973 Free PMC article.

- Economically Motivated Food Fraud and Adulteration in Brazil: Incidents and Alternatives to Minimize Occurrence. Tibola CS, da Silva SA, Dossa AA, Patrício DI. Tibola CS, et al. J Food Sci. 2018 Aug;83(8):2028-2038. doi: 10.1111/1750-3841.14279. Epub 2018 Jul 18. J Food Sci. 2018. PMID: 30020548 Review.

- Detection of apple juice adulteration using near-infrared transflectance spectroscopy. León L, Kelly JD, Downey G. León L, et al. Appl Spectrosc. 2005 May;59(5):593-9. doi: 10.1366/0003702053945921. Appl Spectrosc. 2005. PMID: 15969804

- Assessment of Meat Content and Foreign Object Detection in Cattle Meatballs Using Ultrasonography, Radiography, and Electrical Impedance Tomography Imaging. Ulum MF, Maryani, Rahminiwati M, Choridah L, Setyawan NH, Ain K, Mukhaiyar U, Pamungkas FA, Jakaria, Garnadi AD. Ulum MF, et al. Int J Food Sci. 2024 Aug 1;2024:9526283. doi: 10.1155/2024/9526283. eCollection 2024. Int J Food Sci. 2024. PMID: 39119017 Free PMC article.

- Microfluidic paper analytic device (μPAD) technology for food safety applications. Soman SS, Samad SA, Venugopalan P, Kumawat N, Kumar S. Soman SS, et al. Biomicrofluidics. 2024 May 2;18(3):031501. doi: 10.1063/5.0192295. eCollection 2024 May. Biomicrofluidics. 2024. PMID: 38706979 Free PMC article. Review.

- Double lateral flow immunosensing of undeclared pork and chicken components of meat products. Zvereva EA, Hendrickson OD, Dzantiev BB, Zherdev AV. Zvereva EA, et al. J Food Sci Technol. 2024 Jun;61(6):1148-1156. doi: 10.1007/s13197-024-05944-y. Epub 2024 Feb 28. J Food Sci Technol. 2024. PMID: 38562594

- Highly Sensitive Immunochromatographic Detection of Porcine Myoglobin as Biomarker for Meat Authentication Using Prussian Blue Nanozyme. Hendrickson OD, Zvereva EA, Dzantiev BB, Zherdev AV. Hendrickson OD, et al. Foods. 2023 Nov 24;12(23):4252. doi: 10.3390/foods12234252. Foods. 2023. PMID: 38231679 Free PMC article.

- Designing a novel method based on multiplex PCR for detecting various meat of birds in processed ground meat products. Rajaei N, Doosti A. Rajaei N, et al. Food Chem (Oxf). 2023 Jul 13;7:100177. doi: 10.1016/j.fochms.2023.100177. eCollection 2023 Dec 30. Food Chem (Oxf). 2023. PMID: 38155685 Free PMC article.

Publication types

- Search in MeSH

LinkOut - more resources

Full text sources.

- Taylor & Francis

- MedlinePlus Health Information

- Citation Manager

NCBI Literature Resources

MeSH PMC Bookshelf Disclaimer

The PubMed wordmark and PubMed logo are registered trademarks of the U.S. Department of Health and Human Services (HHS). Unauthorized use of these marks is strictly prohibited.

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- PubMed/Medline

- Google Scholar

- on Google Scholar

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

Mechanisms and Health Aspects of Food Adulteration: A Comprehensive Review

Reviewer 1 Report

In the present manuscript the authors propose a comprehensive review on intentional and unintentional food adulterations and the health impact linked to each adulteration/fraud. The paper is, overall, discretely written and structured. However, I do not consider the manuscript particularly innovative, there are many papers on this topic. A review on such a well-known topic must include recent references and up-to-date information. In this review many bibliographical references are outdated. This means that the literature survey carried out is limited and does not cover the last three years of scientific research on the topic (most recent references are dated 2019). The authors should reconsider their approach to research sources and try to produce an up-to-date paper with all the latest developments in this field. Furthermore, the criteria used to search for references should be clearly stated in the manuscript (dates, databases, keywords). Other specific suggestions are given below.

There is no temporal contextualisation of the various food frauds. What are the emerging adulterations in the last years? Which ones do we really need to worry about? Which frauds are most reported by the competent authorities? Use tools that can provide you data on the most commonly reported adulterations.

You provide a single paragraph on the public health impact of the various contaminants/adulterations. This paragraph provides only generic information without up-to-date information about the real health impact of each contaminant/adulteration. Updated references on actual and certified cases of human health impacts documented in recent years should be included in these sections. Also try to include the real impact that some contaminants might have in relation to new dietary trends, such as the consumption of seaweed, ethnic foods, unconventional foods, etc.

L33-34 It seems to me an imprecise definition. Adulteration of food is not only a question of change in nutritional properties, but there are other factors to consider as you have specified at several points in the paper.

L47-52 Include a reference to support the statement.

L83-86 Data from many years ago. Provide recent data on food-borne diseases.

L205-214 Colouring agents are only used in fruit, vegetables, egg, spices, and honey? Are there cases of fraud involving the addition of colouring agents in meat or fish?

L239-246 There are other substances besides formalin that are used fraudulently. In addition, please provide other details about formalin. Are there threshold values for formaldehyde? It is suggested to use recent references, as example:

· Jinadasa, B. K. K. K., Elliott, C., & Jayasinghe, G. D. T. M. (2022). A review of the presence of formaldehyde in fish and seafood. Food Control, 108882.

L228-232 Include a reference to support the statement.

L287-343 Briefly describe the recent methods for detecting a substitution fraud for each food category.

Table 7. I think that should be appropriate to extend the analysis of pesticide to other countries besides Bangladesh.

L580-587 There is no mention of metal contamination in fish and other marine products (e.g. seaweed). I think it is very important to include data on this. There are many papers on metal contamination in seafood, as example:

· Arulkumar, A., Nigariga, P., Paramasivam, S., & Rajaram, R. (2019). Metals accumulation in edible marine algae collected from Thondi coast of Palk Bay, Southeastern India. Chemosphere, 221, 856-862; Liu, Q., Liao, Y., & Shou, L. (2018).

· Panebianco, F., Nava, V., Giarratana, F., Gervasi, T., & Cicero, N. (2021). Assessment of heavy-and semi-metals contamination in edible seaweed and dried fish sold in ethnic food stores on the Italian market. Journal of Food Composition and Analysis, 104, 104150;

· Liu, Q., Liao, Y., & Shou, L. (2018). Concentration and potential health risk of heavy metals in seafoods collected from Sanmen Bay and its adjacent areas, China. Marine Pollution Bulletin, 131, 356-364.

L589-595 Too general. I do not know if it is appropriate to include a section on microbial contamination in a review on food adulteration. If you really want to provide this, more information should be given including all food categories and the main microbiological issues related to each food.

L617-630 Too generic. With regard to fish, for example, which families are histamine-risk?

In conclusion, in my opinion this manuscript needs a thorough revision before being reconsidered for publication. I hope I have provided you some input for improving the manuscript. I believe that a review on such an important topic should not be merely descriptive, but closely contextualised with the current historical period and updated with the latest news on the topic.

Author Response

Reviewer#1:

Response to Reviewer: Noted. We have removed the outdated bibliographic references and added information from recent publications. The keywords used to search for references have been stated on page 3.

Response to Reviewer: Noted. We have added recent food adulteration incidents on page 2 and 3.

Response to Reviewer: Agreed and noted. We understand that health impact of food adulteration is a wide and important issue. To give this topic due priorities we are preparing a separate manuscript on health impact of food adulteration. Your suggestions would be highly useful for our upcoming manuscript. In this manuscript we provide a brief overview of health impacts to keep this manuscript concise and to avoid any repetition.

Response to Reviewer: Agreed and Noted. We have revised and updated the definition of food adulteration on page 1.

Response to Reviewer: Agreed and Noted. We have included reference no. 8 on page 2 to support the statement.

Response to Reviewer: Agreed and Noted. We have included recent data on food-borne diseases on page 2 and 3.

Response to Reviewer: Noted. We have updated the information regarding colouring agents in food on page 10.

- Jinadasa, B. K. K. K., Elliott, C., & Jayasinghe, G. D. T. M. (2022). A review of the presence of formaldehyde in fish and seafood. Food Control, 108882.

Response to Reviewer: Noted. We have added some details about formalin on page 12.

Response to Reviewer: Noted. We have added reference 59 on page 11 to support the statement.

Response to Reviewer: Noted. Detection of food adulteration and food substitution are not within the scope of the manuscript. To keep the manuscript brief and focused, we haven’t included detection methods and techniques in this manuscript.

Response to Reviewer: Agreed and noted. The authors have prior publications to reduce the above issues.

Ref 1: Khan and Rahman (2017) Pesticide Residue in Foods – Sources, Management, and Control https://doi.org/10.1007/978-3-319-52683-6

Ref 2: Debnath and Khan (2017). Health Concerns of Pesticides. In: Khan, M., Rahman, M. (eds) Pesticide Residue in Foods. Springer, Cham. https://doi.org/10.1007/978-3-319-52683-6_6

To keep this article concise and focused we have removed the table in the revised version.

Arulkumar, A., Nigariga, P., Paramasivam, S., & Rajaram, R. (2019). Metals accumulation in edible marine algae collected from Thondi coast of Palk Bay, Southeastern India. Chemosphere, 221, 856-862; Liu, Q., Liao, Y., & Shou, L. (2018).

Panebianco, F., Nava, V., Giarratana, F., Gervasi, T., & Cicero, N. (2021). Assessment of heavy-and semi-metals contamination in edible seaweed and dried fish sold in ethnic food stores on the Italian market. Journal of Food Composition and Analysis, 104, 104150;

Liu, Q., Liao, Y., & Shou, L. (2018). Concentration and potential health risk of heavy metals in seafoods collected from Sanmen Bay and its adjacent areas, China. Marine Pollution Bulletin, 131, 356-364.

Response to Reviewer: Agreed. We have mentioned the metal contamination in fish and other marine products on page 25 and 26.

Response to Reviewer: Agreed and noted. Microbial contamination is a category of incidental food adulteration. We provided a brief overview of all the incidental food adulterants because all these types seem huge to discuss in detail.

Response to Reviewer: Noted. We provided a brief overview of all the incidental food adulterants to keep the manuscript concise and focused.

Response to Reviewer: Agreed and noted. This time, we tried to contextualize the manuscript with current historical period.

Reviewer 2 Report

This review is generally interesting for scientists working in the field (e.g. Food Scientists, Food Engineers, Analytical Chemists) and it can be published after some revision. In particular, a better grouping of the information can be provided.

In order to improve the quality of this review article, I have the following suggestions:

Some further kind of fraud should also be mentioned, such as:

§ Adulteration of fresh cow milk with reconstituted milk powder (e.g. in paragraph 4.1.3.) ( https://doi.org/10.1016/j.talanta.2019.120223 ).

§ Mislabelling of honey in respect of its botanical origin (pine, thyme, orange blossom, chestnut, heather etc) and of course the most expensive honey, “Manuka” honey ( https://doi.org/10.1016/j.vibspec.2022.103439 , https://doi.org/10.1007/s13197-021-05181-7 ).

§ Mislabelling of various products in respect to their geographical origin. This case applies for famous product due to its geographical origin (e.g. foodstuffs with Protected Designation of Origin, such as “Fava Santorinis” ( http://dx.doi.org/10.1016/j.foodchem.2016.06.088 ) and lentils “Eglouvis” (http://dx.doi.org/10.1017/S1479262118000096).

Olive oil is a product of high concern and I think some more information can be added (e.g. https://doi.org/10.1016/j.talanta.2020.120920 , https://doi.org/10.1016/j.aca.2018.02.042 ).

Figure 1 and Page 5: “Dilution and overdilution” and “enhancement of food weight” have been written under the group of methods to improve physical and sensory properties. However, both dilution and increase of food weight are (similar) methods for adulteration and not to improve physical and sensory properties. They consist an individual category.

Figure 1, “Organic and Synthetic adulterants”: My recommendation is to provide general groups of adulterants (e.g. artificial sweetening agents, artificial coloring agents) without specifying the foodstuffs that are applied (e.g. milk, wine, etc).

I think a paragraph about the strategy of chemical analysis for the detection/ quantification of adulteration will be helpful for the reader. In brief, chemical analysis can be emphasized to specific analytes implying adulteration (e.g. melamine, antibiotics) or to provide a fingerprinting of the targeted original foodstuff (multivariate description of its chemical composition). In the latter case, we need to study a wide number of original (reference) samples and then to analyse the unknown samples. Comparison of the chemical description between the reference samples and unknown ones can be performed by means of chemometric techniques (e.g. class modelling, https://doi.org/10.1016/j.aca.2017.05.013 ). Some relevant reviews can be added, such as https://doi.org/10.1002/jsfa.8364

Conclusions: It should be extensively re-written. Do not duplicate text of the Abstract (e.g. “this article provides a picture of current food adulteration..”). The section of conclusions is not like an abstract. Focus on conclusions, on the scope, on limitations and future perspectives.

Minor remarks:

Lines 79-83: I suggested authors use more recent information and update these data, as they reported in ref. 16 and 17, published in 2013 and 2014, respectively.

Lines 117-118: Some examples can be added.

Line 129: I suggest authors to remove the words “honey contamination from” because the use/ consumption of genetically modified plants is a more general problem.

Line 169: (i) Replace “coper” with “copper” and (ii) copper sulfate can not be considered as a growth hormone.

Lines 551-554: A better grouping of drugs is required. For example, aspirin, mefenamic acid and phenacetin are non-steroidal anti-inflammatory drugs.

Line 580 (and Table 1): Replace “heavy metal elements” with “heavy metals”.

Line 585: I have some reservations if Zn is a really toxic element.

Line 586: “Heavy metal and lead..”: Lead is also a heavy metal, isn’t it?

Lines 651-652: “..penicillin, …, β -lactams, …”: Penicillin is also a β -lactam antibiotic, why did authors distinguish penicillin from β -lactams?

“Trace and heavy elements” (e.g. Table 9): I suggest to replace it my “heavy metals and organometallic species”.

Adulteration of fresh cow milk with reconstituted milk powder (e.g. in paragraph 4.1.3.) (https://doi.org/10.1016/j.talanta.2019.120223).

Response to Reviewer: Agreed and Noted. Supporting information has been added on page 14.

Mislabelling of honey in respect of its botanical origin (pine, thyme, orange blossom, chestnut, heather etc) and of course the most expensive honey, “Manuka” honey (https://doi.org/10.1016/j.vibspec.2022.103439, https://doi.org/10.1007/s13197-021-05181-7).

Response to Reviewer: Agreed and Noted. We have added information on page 25.

Mislabelling of various products in respect to their geographical origin. This case applies for famous product due to its geographical origin (e.g. foodstuffs with Protected Designation of Origin, such as “Fava Santorinis” (http://dx.doi.org/10.1016/j.foodchem.2016.06.088) and lentils “Eglouvis” (http://dx.doi.org/10.1017/S1479262118000096).

Olive oil is a product of high concern and I think some more information can be added (e.g. https://doi.org/10.1016/j.talanta.2020.120920, https://doi.org/10.1016/j.aca.2018.02.042).

Response to Reviewer: Agreed and noted. We have included a separate section “Food dilution” and addressed both dilution and enhancement of food weight in that section on page 17.

Response to Reviewer: This comment is not clear to the authors. The comment may not be relevant for this section of the manuscript. Further clarification of the comment would be highly helpful.

I think a paragraph about the strategy of chemical analysis for the detection/ quantification of adulteration will be helpful for the reader. In brief, chemical analysis can be emphasized to specific analytes implying adulteration (e.g. melamine, antibiotics) or to provide a fingerprinting of the targeted original foodstuff (multivariate description of its chemical composition). In the latter case, we need to study a wide number of original (reference) samples and then to analyse the unknown samples. Comparison of the chemical description between the reference samples and unknown ones can be performed by means of chemometric techniques (e.g. class modelling, https://doi.org/10.1016/j.aca.2017.05.013). Some relevant reviews can be added, such as https://doi.org/10.1002/jsfa.8364

Response to Reviewer: Noted. Detection and quantification of food adulteration are not within the scope of the manuscript. To keep the manuscript brief and focused, we haven’t included detection chemical analysis for the detection/quantificaito techniques in this manuscript.

Conclusions: It should be extensively re-written. Do not duplicate text of the Abstract (e.g. “this article provides a picture of current food adulteration..”). The section of conclusions is not like an abstract. Focus on conclusions, on the scope, on limitations and future perspectives.

Response to Reviewer: Agreed and noted. We have rewritten the conclusion focusing on the scope, limitations and future prospects.

Response to Reviewer: Agreed and noted. We have added recent information and data on page 2 and 3.

Response to Reviewer: Agreed and noted. We removed “honey contamination from genetically modified plants” from the manuscript.

Response to Reviewer: Agreed and noted. Replaced “coper” with “copper”. Removed copper sulfate on page 9.

Response to Reviewer: Agreed and noted. We have made a better grouping of drugs on page 22 and 23.

Response to Reviewer: Agreed and noted. We have replaced “heavy metals elements” with “heavy metals” on page 25 and 26.

Response to Reviewer: Agreed. Zn has been removed on page 25 and 26 .

Response to Reviewer: Agreed. Lead has been removed on page 25 and 26.

Lines 651-652: “..penicillin, …, β-lactams, …”: Penicillin is also a β-lactam antibiotic, why did authors distinguish penicillin from β-lactams?

Response to Reviewer: Agreed. We have removed β-lactam on page 28.

Response to Reviewer: Agreed. We have made correction on page 25 and 26.

Reviewer 3 Report

This review paper is a mixture of various issues and topics – food fraud, food defense, food security, food safety and food quality. In parallel, references for defining some of these issues are from authors and journals not recognized as leading ones in these field (and wrong). Finally, incidental food adulteration associated with contaminants that cause food safety are not considered as food fraud, but as food safety outbreaks.

Authors need to know that there are scientific and international recognized definitions of food fraud (types, impacts etc.) which have not been analyzed by the authors. Authors need to revise the paper, clearly define food adulteration (in line with latest papers and recommendation from World Health Organization, US FDA, European Food Safety Authority, etc) and rewrite the entire review (omitting some parts that are totally irrelevant).

Reviewer#3:

Response to Reviewer: Noted and Thanks. We have revised the article, re-written different sections, removed old and insignificant references, added recent and more relevant references, and changed the title of the article.

To define food adulteration, the World Health Organization (WHO) mainly focuses on deliberate adulteration. WHO refers unintentional adulteration of food as food safety incidents. [Ref: https://www.who.int/news-room/fact-sheets/detail/food-safety]

In broad sense, food adulteration is referred to a process in which the quality of food is lowered. According to the US Food and Drug Administration (FDA), “Food can be declared adulterated if: i) a substance is added which is injurious to health, ii) cheaper or inferior quality item added to food, iii) any valuable constituent is extracted from main food article, iv) quality of food is below the standards, v) any substance has been added to increase bulk or weight

- vi) to make it appear more valuable”.

Many authors mention three types of food adulteration: I. Intentional adulteration, II. Metallic contamination, III. Incidental adulteration. In this manuscript, both Metallic contamination (II) and Incidental adulteration (III) are considered under the same category (Unintentional adulteration), since each adulteration involves food quality degradation by unintentional or accidental means.

Ref. 1. Food adulteration: sources, health risks and detection methods, by Sangita Bansal, Apoorva Singh, Manisha Mangal, Anupam K Mangal and Sanjiv Kumar,

DOI: 10.1080/10408398.2014.967834

Ref. 2. An overview of food adulteration: Concept, sources, impact, challenges and detection, by Ankita Choudhary, Neeraj Gupta, Fozia Hameed and Skarma Choton, DOI: 10.22271/chemi.2020.v8.i1am.8655

Ref. 3. Chapter 1 - Food Safety and Quality, by Shyam Narayan Jha, DOI: 10.1016/B978-0-12-420084 5.00001-9

The goal of our study is to aggregate all types of food adulteration in a single frame. Addressing the argument between food adulteration and food safety, we modified the title of our manuscript as, “Mechanisms and Health Aspects of Food Adulteration and Food Safety: A Comprehensive Review”.

“Origin fraud and mislabelling” is a form of food fraud, hence, we addressed it as food fraud.

The authors addressed all the observations improving considerably the manuscript. I believe the work is ready for publication. As a final remark, I only suggest to include in the introduction the databases where you searched for the mentioned keywords.

Reviewer 1:

-The authors addressed all the observations improving considerably the manuscript. I believe the work is ready for publication. As a final remark, I only suggest to include in the introduction the databases where you searched for the mentioned keywords.

Response to Reviewer: Agreed. We have addressed the database in pages 2 and 3.

Momtaz, M.; Bubli, S.Y.; Khan, M.S. Mechanisms and Health Aspects of Food Adulteration: A Comprehensive Review. Foods 2023 , 12 , 199. https://doi.org/10.3390/foods12010199

Momtaz M, Bubli SY, Khan MS. Mechanisms and Health Aspects of Food Adulteration: A Comprehensive Review. Foods . 2023; 12(1):199. https://doi.org/10.3390/foods12010199

Momtaz, Mysha, Saniya Yesmin Bubli, and Mohidus Samad Khan. 2023. "Mechanisms and Health Aspects of Food Adulteration: A Comprehensive Review" Foods 12, no. 1: 199. https://doi.org/10.3390/foods12010199

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

IEEE Account

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

- DOI: 10.22271/chemi.2020.v8.i1am.8655

- Corpus ID: 214332853

An overview of food adulteration: Concept, sources, impact, challenges and detection

- A. Choudhary , N. Gupta , +1 author Skarma Choton

- Published 2020

- Agricultural and Food Sciences, Environmental Science

- International Journal of Chemical Studies

Tables from this paper

56 Citations

Selected food items adulteration, their impacts on public health, and detection methods: a review.

- Highly Influenced

Mechanisms and Health Aspects of Food Adulteration: A Comprehensive Review

Food adulteration, an overview of food adulterants and their health impacts, consumers’ knowledge of food adulteration and commonly used methods of detection, food adulteration and its various facets, a study on consumer awareness on food adulteration, quality and methods of adulteration of meat and fish products on the polish market in 2010-2020., adulteration of sugar: a growing global menace, prospects of nanotechnology advances in food adulterant detection, spoilage detection, packaging and preservation applications, 64 references, food adulteration and contamination in india: occurrence, implication and safety measures.

- Highly Influential

Analysis of Food quality and Food Adulterants from Different Departmental & Local Grocery Stores by Qualitative Analysis for Food Safety

Adulteration and microbiological quality of milk (a review), street-vended foods improvement: contamination mechanisms and application of food safety objective strategy : critical review, estimation of quality of raw milk (open & branded) by milk adulteration testing kit., evaluation of edible oils for argemone mexicana seed oil adulteration., milk adulteration in hyderabad, india – a comparative study on the levels of different adulterants present in milk., food safety research in india: a review., plant extracts for the control of bacterial growth: efficacy, stability and safety issues for food application., a study on chemical composition and detection of chemical adulteration in tetra pack milk samples commercially available in multan., related papers.

Showing 1 through 3 of 0 Related Papers

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Sensors (Basel)

Qualitative and Quantitative Detection of Food Adulteration Using a Smart E-Nose

Associated data.

https://data.mendeley.com/datasets/5yhggs7zy7/1 (accessed on 1 July 2022).

Food adulteration is the most serious problem found in the food industry as it harms people’s healths and undermines their beliefs. The present study is focused on designing and developing a smart electronic nose (SE-Nose) for the qualitative and quantitative fast-track detection of food adulteration. The SE-Nose methodology is comprised of a dataset, sample slicing window protocol, normalization, pattern recognition, and output blocks. The dataset pork adulteration in beef is used to validate the SE-Nose methodology. The sample slicing window protocol extracts the early part of the signal. The sample slicing window protocol and pattern recognition models (classification and regression models) together achieved the high-performance and fast-track detection of pork adulteration in beef. With classification models, the qualitative analysis of adulteration is measured, and with regression models, the quantitative analysis of adulteration is measured. An accuracy of 99.996% and an RMSE of 0.02864 were achieved with the SVM classification and regression model. The recognition time in detecting pork adulteration in beef with SVM models is 40 s. With the proposed SE-Nose methodology, the recognition time is reduced by one-third. To validate the classification and regression models, a 10-fold cross-validation method was used.

1. Introduction

Growing demand for nutritious, high-quality, and safe food has made the food industry and consumers pay more attention. Food adulteration is the biggest problem in the food supply chain and is prevalent at various levels. Food adulteration, committed wittingly or unwittingly, is a major problem and can have severe consequences for people with food intolerances, lifestyles, and religious practices. The most common reasons for food adulteration entail substituting high-value food products with low-value food products for financial profits [ 1 , 2 ]. Beef is one of the most widely consumed of all meats because it is low in fat, high in protein, vitamins, amino acids, and other essential nutrients required for human beings [ 3 ]. According to the United States Department of Agriculture’s (USDA) world market and trade reports, the United States is anticipated to be the world’s top producer and exporter of beef in 2022 [ 4 ]. Because of its high consumption and economic benefits, beef is the prime target for adulteration and is most frequently adulterated with pork due to its lower economic value. Consumers object to such adulterations for allergic, cultural, monetary, religious, and consumer rights reasons [ 5 , 6 ]. In an investigation conducted in China on 1553 media reports, of the total instances of adulteration, animal-based food makes up 37.78% [ 7 ]. Halal-certified meat pies served to prisoners in UK jail in 2013 were found to contain pork DNA in them [ 8 ]. With the horse meat scandal incident in 2013, the demand for beef authentication has increased significantly [ 9 ]. With these types of incidents, there is a rise in the need for an accurate and reliable method of detecting beef adulteration.

To detect beef adulteration, various techniques are employed such as molecular biology-based methods [ 10 , 11 , 12 , 13 , 14 , 15 , 16 ], spectroscopy methods [ 3 , 6 , 17 , 18 , 19 , 20 , 21 ], chromatographic methods [ 22 , 23 , 24 ], and enzyme-linked immunological methods [ 25 , 26 , 27 ]. However, the equipment to implement such techniques is expensive, poor in real time, time consuming, destructive, laborious, and requires technical supervision. Additionally, the equipment requires highly skilled individuals to conduct the experiment and analyze the results. This demands the development of an instrument that is simple, accurate, economical, portable, quick, highly sensitive, and requires fewer samples for measurement.

An electronic nose (E-nose) is a device that mimics a human’s sense of smell. It is simple, sensitive, reliable, low-priced, non-destructive, and highly correlated with the detection of various odor signatures. An E-nose is built up of an array of sensors, signal processing units, and a pattern recognition system to measure the testing sample. The sensors that are used for the design of a sensor array are metal-oxide semiconductor (MOS) gas sensors [ 28 ], metal-oxide semiconductor field effect transistors (MOSFET) gas sensors [ 29 ], acoustic wave gas sensors [ 30 ], quartz crystal micro balance sensors [ 31 ], infrared sensors [ 32 ], colorimetric sensors [ 33 ], fluorescence sensors [ 34 ], conducting polymer gas sensors [ 35 ], and fiber optic gas sensors [ 36 ], among others. Data from the sensor array are received by the signal processing unit and pre-processes the data as per the requirement. A pattern recognition system performs the classification or regression of the processed data to measure the sample. The development at all stages of E-nose design made it a good alternative to traditional methods. E-nose is employed in different food industries such as the meat industry [ 37 , 38 ], oil industry [ 39 ], alcohol industry [ 40 ], tea industry, [ 41 ] etc. Furthermore, the E-nose is used in various food industry applications such as adulteration detection [ 42 ], origin identification [ 43 ], authentication [ 44 , 45 ], grading [ 46 , 47 ], freshness assessment [ 40 ], and shelf-life determination [ 48 ]. In this study, we develop a smart E-Nose (SE-Nose) for the qualitative and quantitative analysis of pork adulteration in beef. The smartness of the E-Nose is achieved by introducing a sample slicing window protocol (SSWP) for fast-track detection, designing a less complex system, qualitative analysis of adulteration using artificial intelligence-based classification models, and the quantitative analysis of adulteration using regression models, and achieving higher accuracies. In other parts of this section, an extensive literature analysis of evaluating the E-nose to identify beef adulterated with pork is described.