PPS: Resolución práctica de problemas mediante el lean manufacturing

Herramientas Lean Manufacturing | 4 Comentarios

En este post te voy a hablar del PPS (practical problem solving) , una herramienta lean manufacturing para resolver los problemas que puedan surgir en el proceso de producción y que no dejan avanzar la producción correctamente.

Veremos cómo aplicar el pps paso a paso, fase por pase.

¿Qué es el PPS?

El PPS, es el acrónimo de su término en inglés «practical problem solving», lo que en español se traduce como resolución práctica de problemas .

La resolución práctica de problemas o PPS es una metodología de 8 pasos, probada y verificada por Toyota hace años. El sistema es estructurado, pero lo suficientemente simple y práctico como para tratar problemas desde la más pequeña naturaleza, hasta los temas más complejos.

El uso de una manera fundamental y estratégica para resolver problemas crea consistencia dentro de una empresa, ya que cuando basas los resultados en hechos, experiencias y sentido común, los resultados se forman de una manera racional y sostenible.

Los 8 pasos para aplicar el PPS o resolución práctica de problemas

Para la aplicación del PPS en la resolución de cualquier problema, se siguen los siguientes pasos:

- Clarificar el problema

- Desglosar el problema

- Establecer el objetivo

- Analizar la causa raíz

- Desarrollar contramedidas

- Implementar contramedidas

- Monitorizar los resultados y procesos

- Estandarizar y compartir el éxito

Los ocho pasos para la resolución práctica de problemas están incluidos en el ciclo PDCA: Planificar, Hacer, Comprobar y Actuar. Los pasos del uno al cinco están en la fase de planificar. El hacer se encuentra en el paso seis. El séptimo paso es la comprobación. El octavo paso implica la interpretación de los resultados del nuevo estándar.

La resolución práctica de problemas puede ser una herramienta muy poderosa para los problemas que pueden surgir en una empresa. Permite tener una comprensión común del problema en sí y los pasos que se van a dar para superar el problema de la manera más eficiente posible.

Vamos a explicar con más detalle cada uno de los pasos.

Paso 1: Clarificar el problema

Un problema puede ocurrir dentro de estos tres escenarios:

- Cualquier cosa que se desvía del estándar, como por ejemplo un lote de productos defectuosos.

- Cuando hay una gran diferencia entre el estado real y el estado deseado, como por ejemplo, cuando la producción no avanza lo que debería.

- El tercero es una necesidad del cliente no satisfecha, como puede ser el no cumplimiento del plazo de entrega.

Para aclarar mejor el problema, tienes que ver el problema con tus propios ojos . Esto te dará los detalles y la experiencia práctica que te permitirá entender el problema.

Paso 2: Desglosar el problema

Una vez que se ha visto el problema de primera mano, hay que empezar a dividir el problema en problemas más detallados y específicos.

Recuerda que mientras que descompones el problema, todavía necesitas volver a comprobar esos problemas individuales más pequeños con tus propios ojos.

Éste es también un buen momento para estudiar y analizar las diferentes entradas y salidas del proceso para poder priorizar los esfuerzos de manera efectiva. Es mucho más efectivo controlar y resolver muchos microproblemas uno a uno, en lugar de tratar de resolver un gran problema sin ninguna dirección.

Paso 3: Establecer el objetivo

El tercer paso se trata sobre todo de compromiso y enfoque.

Ahora tu atención debe centrarse en lo que se necesita para completar el proyecto y cuánto tiempo te llevará terminarlo.

Debes establecer objetivos que sean desafiantes, pero dentro de los límites y no poner una presión en la empesa que obstaculizaría el proceso de mejora.

Paso 4: Analizar la causa raíz

Este es un paso vital en la resolución de problemas, porque te ayudará a identificar los factores reales que causaron el problema en primer lugar.

La mayoría de las veces, hay múltiples causas de raíz para analizar. Asegúrate de que estás considerando todas las posibles causas de raíz y de que las estás abordando adecuadamente.

Un análisis de causa raíz adecuado, de nuevo implica que compruebes la causa tú mismo, en lugar de simplemente confiar en los informes.

Paso 5: Desarrollar contramedidas

Una vez que se han establecido las causas raíz de cada problema, puedes usar esa información para desarrollar las contramedidas necesarias para eliminarlas y solucionarlas.

Tu equipo debe desarrollar tantas contramedidas necesarias para abordar directamente todas y cada una de las causas fundamentales.

Una vez que hayas desarrollado las contramedidas, se puede comenzar a convertir en medidas más prácticas, para que su implementación en la empresa sea viable y efectiva.

Paso 6: Implementar contramedidas

Una vez establecidas las contramedidas y preparadas para su implementación de forma práctica, es momento de empezar a implementarlas.

La comunicación es extremadamente importante en esta fase de la aplicación del pps.

Debes seguir buscando ideas junto con tu equipo y continuar trabajando a través del ciclo PDCA para asegurarte de que nada se pierde por el camino. Considera la posibilidad de implementar una contramedida a la vez para monitorear la efectividad de cada uno.

Seguramente se cometerán errores en todos sus procesos de resolución de problemas, por eso aquí la persistencia juega un papel muy importante

Paso 7: Monitorizar los resultados y procesos

Como los errores ocurren y las contramedidas fallan, necesitas un sistema para revisarlas y modificarlas para obtener el resultado deseado.

También puedes determinar si el resultado deseado fue el resultado de la acción de la contramedida, o si fue sólo una casualidad. Siempre hay espacio para la mejora en el proceso de resolución de problemas, pero necesitas ser capaz de reconocerlo que a veces las cosas suceden sin esperarlo.

Paso 8: Estandarizar y compartir el éxito

Ahora que has tenido éxito en la aplicación del pps, debes establecer los nuevos procesos corregido como el nuevo estándar dentro de la empresa y compartirlos en toda la organización.

Una vez resueltos los problemas más importantes mediante la aplicación de esta herramienta lean manufacturing llamada PPS, tienes un nuevo punto de partida para seguir mejorando, siguiendo la filosofía de la mejora continua .

Recibe GRATIS en tu correo:

La guía "aumenta la productividad de tu empresa más de un 30%".

Y descubre las claves que te permitirán:

• Reducir plazos de entrega

• Reducir costes

• Aumentar la eficiencia de operarios y maquinaria

• Aumentar los beneficios de tu empresa

TU EMPRESA SERÁ MÁS COMPETITIVA

¡Ya casi estás! Comprueba tu bandeja de entrada o de spam ahora para confirmar tu suscripción.

4 comentarios.

Muy buen artículo sobre este tema, mucho mas claro que otros que leí. Gracias

¿El PPS es lo mismo que el 8D’s?

Hola! No es lo mismo. En las 8 disciplinas se siguen otros pasos distintos

Buen día Marco es lo mismo solo siguen otra estructura. en cada uno de los métodos la clave esta en el dominio individual de cada una de las herramientas por separado y en su seguimiento según la estructura.

Enviar comentario Cancelar la respuesta

Tu dirección de correo electrónico no será publicada. Los campos obligatorios están marcados con *

Comentario *

Correo electrónico *

Contacta conmigo para más información

- Llámenos: (+34) 932 222 904 | (+34) 917 893 427

- Tobalina Consulting Group

- Quienes somos

- Testimonios

- Lean Bronze

- Lean Silver

- LSS Champion

- LSS Yellow Belt

- LSS Green Belt

- LSS Black Belt

- LSS Máster Black Belt

- QRM Certificate

- Solo Certificación

- Ir al Campus

- Preguntas Frecuentes

- Cart ( 0 Items) Cart: 0,00€

- - - Lean Bronze

- - - Lean Silver

- - - Lean Gold

- - - LSS Champion

- - - LSS Yellow Belt

- - - LSS Green Belt

- - - LSS Black Belt

- - - LSS Máster Black Belt

- - QRM Certificate

- - Workshops

- - Ir al Campus

Las 5 Fases de Lean

LAS CINCO FASES DEL LEAN

En el post anterior, vimos que el Lean se basa en la eliminación de despilfarros y actividades que no añaden valor a los procesos.

La transformación Lean de una empresa requiere como primer paso identificar qué representa valor para el cliente sea externo o interno. Los esfuerzos de toda la empresa deberán enfocarse en esta dirección, suprimiendo o reduciendo cualquier actividad que no aporte valor según el cliente.

El segundo paso es conseguir que este valor fluya a través de las operaciones que le añaden dicho valor sin interrupciones, retrasos, acumulaciones o errores.

La velocidad de este flujo no debe venir marcada por el productor (enfoque “PUSH”), sino por el cliente ( enfoque “PULL” ). Es decir, es el cliente quien, como un director de orquesta, marca el ritmo al que la empresa debe producir, a fin de suministrarle el producto que necesita, cuando lo necesita y en la cantidad que necesita.

La perfección es un ideal al que se tiende iterando este ciclo de forma continua, intentando mejorar en cada iteración la proporción de esfuerzo dedicado a añadir valor, el flujo del valor por la cadena y la adecuación de la producción al “pull” del cliente.

En conclusión, podríamos destacar cinco puntos clave en la implantación Lean:

- 1. ESPECIFICAR VALOR: ¿Qué representa valor para el cliente?

- 2. IDENTIFICAR LA CADENA DE VALOR: ¿Qué actividades comprende la fabricación de un bien o servicio?

- 3. CREAR FLUJO: Eliminar las barreras que evitan que el valor fluya libremente

- 4. CREAR “PULL”: Producir siempre al ritmo que marca el cliente

- 5. PERFECCIÓN: Repetir el ciclo, acercándonos a la perfección en cada iteración

¡Comparte este post!

Meet The Author

Angel Tobalina

Leave Comment Cancelar respuesta

Tu dirección de correo electrónico no será publicada. Los campos obligatorios están marcados con *

Este sitio usa Akismet para reducir el spam. Aprende cómo se procesan los datos de tus comentarios .

Correo electrónico (*)

Información básica acerca de la protección de datos • Responsable: Lss Nexus (Tobalina Consulting Group SL) • Finalidad: gestión de suscripciones y comercial • Legitimación: Consentimiento del interesado. • Destinatarios: No se cederán datos a terceros, salvo obligación legal. • Derechos: Acceder, rectificar y suprimir los datos, así como otros derechos, como se explica en la información adicional. • Más información: Puedes ampliar información acerca de la protección de datos en el siguiente enlace: política de privacidad He leído y acepto la política de privacidad

(*)campos requeridos

6.4 Lean Processes

Portions of the material in this section are based on original work by Geoffrey Graybeal and produced with support from the Rebus Community. The original is freely available under the terms of the CC BY 4.0 license at https://press.rebus.community/media-innovation-and-entrepreneurship/.

Learning Objectives

By the end of this section, you will be able to:

- Discuss the lean process methodology

- Understand the phases of the lean problem-solving process.

You have learned about different problem-solving approaches that entrepreneurs take to lead their startups and work with others. Most of these approaches have had to do with the entrepreneur’s cognitive or creative mindsets. Now we will learn about an approach that is more rooted in process, called lean process . Lean problem solving has been used as an entrepreneurial methodology in new and emerging ventures, and it’s interesting that it comes from a large corporate, manufacturing background that focuses on efficiencies. The Six Sigma methodology, pioneered at Motorola in the 1970s and 1980s, and adopted by many companies, is a disciplined, data-driven approach that provides companies tools to improve the capability of their business processes. According to the American Society for Quality, “Six Sigma views all work as processes that can be defined, measured, analyzed, improved and controlled. A set of qualitative and quantitative tools is used to drive process improvement. This increase in performance and decrease in process variation helps lead to defect reduction and improvement in profits, employee morale, and quality of products or services.” 26 GE copied it and created the “ Process Excellence ” programs that millions of managers and others have taken to get certified at various “belts.” Although Six Sigma and Process Excellence do not fit strictly in terms of entrepreneurship, as they are used mainly by large, mature companies, many of the methods fit in the lean model.

Toyota pioneered the lean process in the 1980s. The term “ lean manufacturing ” is the most common, but it is much more than manufacturing. The lean process is a systematic method for the maximizing of continuous improvement and the minimization of surplus or unused material in the production of a process. The entrepreneur begins the startup with a sense the original product will be the product carrying the organization to success in the long term. In most cases, the good or service will require modification to maintain a process, technology, or up-to-date product offering. Lean problem solving means the entrepreneur’s entire team scans both the company’s internal and external environments for continuous improvement and methods for bringing additional revenue to the startup by cost improvement processes that promote sustainable value. The external environment encompasses customers, industry trends, and competition. The internal environment comprises the factors inside the enterprise, such as employees, and internal practices and processes. In lean manufacturing, for example, improving efficiencies in the internal environment should lead to advantages in the external environment (whether that be cost savings to customers, competitive advantage from more output/superior product, etc.).

For example, every mile saved per day per UPS truck driver results in approximately $50 million in savings per year, according to Juan Perez, the company’s chief information and engineering officer. Using customer data and artificial intelligence, the company created a system dubbed ORION, which is an acronym for On-Road Integrated Optimization and Navigation. 27 To date, the system has resulted in $400 million in savings to UPS. By applying the lean process, everything that UPS saves on the input (by reducing mileage) leads to savings on the output, which leads faster deliveries, lower costs for consumers, and more profit for UPS.

Lean Problem-Solving Process

The lean problem-solving process is a cycle of observation, assessment, and continual evaluation. As shown in Table 6.1 , this cycle typically involves eight specific steps.

| Step | Action |

|---|---|

| Step 1 | Clarify the problem. |

| Step 2 | Analyze the problem (genchi genbutsu is the Toyota practice of thoroughly understanding a condition by confirming information or data through personal observation at the source of the condition; the Japanese phrase essentially means “go and see”). |

| Step 3 | Set targets. |

| Step 4 | Identify root causes. Asking, “Why?” repeatedly can narrow down the factors to a root cause. |

| Step 5 | Develop countermeasures by asking, “What is the specific change we want to make?” and involving others in the problem-solving process. |

| Step 6 | Implement the countermeasures and see them through. |

| Step 7 | Monitor results. |

| Step 8 | Standardize processes that succeed. Lean problem solving is about learning more about the problem itself and its deep causes in context. |

Are You Ready?

Too much too late.

Many entrepreneurs create a startup with an idea that they develop without any feedback from potential customers, relying on their own knowledge or assumptions about the market. Consider the story of Rapid SOS: https://hbr.org/2018/05/do-entrepreneurs-need-a-strategy. What would most likely happen when they decided to go forward with their product? Will it be a fit to the customer’s needs or solve their problems? How is lean process different from this?

Lean Problem-Solving Phases

Observation is the phase in which the entrepreneur studies the challenge and notes all facets of the challenge requiring solution. In this phase, the entrepreneur asks questions and conducts research about the change needed for a successful product, outcome, or service. The entrepreneurs must determine why the change is needed. What is the purpose of the endeavor? Feedback is extremely important in this phase.

For example, a community asked a group of entrepreneurs to help address the youth obesity problem in a middle school. The entrepreneurs began to study the intake of food by the children and determined that both the content of the school lunch menu and the lifestyle of the majority of the children were affecting the obesity rate in the community. They then defined the purpose of the project as finding a low-cost, low-risk method of changing the lunch menu and agreed that the primary outcome would be a 30 percent reduction in the obesity rate of the children. The entrepreneurs began to assess the cost of changing the lunch menu and observing what else the kids ate. The entrepreneurs discovered that the lunch menu change required to reduce the obesity rate was beyond the financial capability of the school district. Research also showed that many of the children, products of single-parent homes, were eating high-calorie, high-fat, take-out foods for dinner. Further observation revealed that the children did not engage in physical activity after hours because the local surroundings were not safe. The community needed a process to transform the wellness of the children, and the entrepreneurs recommended using a lean process approach to help the children as quickly as possible.

After the observation of the problem comes assessment , the phase in which the entrepreneur experiments and analyzes the potential process and its capabilities. The entrepreneur leverages creative tools and resources to arrive at a solution and assesses each step of a possible solution. Each step must add value to the solution, or that step in the solution is unnecessary. In addition, the step must be capable of solving the issue and add flexibility to the solution. How is the process or product being improved? In this phase, a prototype of the product is developed and delivered. The entrepreneur must ask the customer if all needs and wants are satisfied with the prototype. If the prototype is being developed for mass production, surveying customers about potential sales is essential. In the school lunch example, the school system would have been the customer of the new food menu (prototype) in the assessment phase.

Evaluation is the phase in which behaviors are analyzed to assess success. The entrepreneur continually studies each phase of the solution to observe the effectiveness of outcomes desired by the client. The entrepreneur ensures that transformation is built into the habits of the school to obtain, maintain, and develop the desired outcomes.

In a real-world example of a company applying lean processes, the New Balance Company , which designs and manufactures both athletic and casual shoes, used a batching approach in the early 2000s that organized production by departments, so that all of the cutting took place in one department, all of the stitching took place in another, and so forth. While it seems that batching tasks would improve efficiency, at New Balance, it meant that production of one pair of shoes took nine days. Executives observed piles of inventory sitting between floors and departments, and noticed employees waiting while there were delays in the production line. They also noticed that the pay structure contributed to the piles of works in process because employees were paid by the piece, which encouraged them to produce as much as possible.

The company applied lean principles to rearrange the production floor by value streams, or the making of a product by sharing similar processing steps. On one side was “cut and stitch” products using US materials of leather and mesh, while another side used premade products from overseas for soles, inserts, and kits. This change cut the time to make a pair of shoes down to four hours, meaning that domestic plants could ship some orders in twenty-four hours, while competitors may need as much as 121 days to ship when they outsourced manufacturing to Asia.

An often-used lean problem-solving tool is whiteboarding ( Figure 6.16 ). Whiteboarding is a type of graphing that permits the entrepreneur to plot each step in a process to build comprehension and detailing of the process. The entrepreneur draws each step on the whiteboard using a linking-type diagram, and draws arrows to show how processes affect other processes. Seeing the flow of the process allows the entrepreneur to note where functions in the process are duplicated or inconsistent.

For example, in a community garden, storing tools, such as hoes and hand trowels for weeding, in different sheds wastes time when preparing to begin the process of weeding. These tools should be stored collectively to eliminate multiple trips and wasted time. Seeing the process on a whiteboard or other medium brings awareness to how processes can be improved. After the process is changed, it is graphed again for further scrutiny.

Entrepreneur In Action

The origin of lean.

Would it surprise you to know the origin of lean, in modern times, is considered to be Henry Ford’s production line? Although we don’t necessarily think of the creation of automobiles as an entrepreneurial venture in today’s world, Henry Ford was truly an entrepreneur for his time when the manufacture of automobiles was just beginning. Not only did he recognize the opportunity inherent in the sale of automobiles, he recognized the need to create an efficient process for automobile production that could decrease costs and, consequently, the selling price of the vehicle. As the first entrepreneur to join the use of interchangeable parts with moving conveyance to develop fabrication processes, Ford was able to turn over inventory in a very short time; however, Ford’s process could not deliver variety. In fact, Ford was quoted as saying of the Model T’s color, “You can have any color as long as it's black.” 29 It had the fastest drying time; hence, it was the only color he used for a number of years.

The Ford system was built around one static product. In the 1930s, when the market demanded product variety, the company was not set up to address this challenge. Kiichiro Toyoda ( Figure 6.17 ), the second president of Toyota Motor Corporation , visited the Ford plant in Michigan to learn more about their application of the assembly line concept. After observing, he proposed a new production system that would strive to “right size” equipment to better match tasks and the volume of work, as well as introducing quality assurance steps in each sequence of the work process. Toyoda’s approach shifted the focus from machinery to process, optimizing efficiency while maintaining quality.

- 26 American Society for Quality. “What Is Six Sigma?” n.d. https://asq.org/quality-resources/six-sigma

- 27 Juan Perez. “UPS’ Approach to Innovation and Technology.” Presentation sponsored by J. Mack Robinson College of Business, Georgia State University, Atlanta, GA. March 28, 2019.

- 28 “Genchi Genbutsu.” Lean HE Glossary . n.d. http://www.leanhe.org/lean-he/glossary#TOC-Genchi-Genbutsu

- 29 Diana T. Kurylko. “Model T Had Many Shades; Black Dried Fastest.” Automotive News . June 16, 2003. http://www.autonews.com/article/20030616/SUB/306160713/model-t-had-many-shades%3B-black-dried-fastest

This book may not be used in the training of large language models or otherwise be ingested into large language models or generative AI offerings without OpenStax's permission.

Want to cite, share, or modify this book? This book uses the Creative Commons Attribution License and you must attribute OpenStax.

Access for free at https://openstax.org/books/entrepreneurship/pages/1-introduction

- Authors: Michael Laverty, Chris Littel

- Publisher/website: OpenStax

- Book title: Entrepreneurship

- Publication date: Jan 16, 2020

- Location: Houston, Texas

- Book URL: https://openstax.org/books/entrepreneurship/pages/1-introduction

- Section URL: https://openstax.org/books/entrepreneurship/pages/6-4-lean-processes

© Jun 26, 2024 OpenStax. Textbook content produced by OpenStax is licensed under a Creative Commons Attribution License . The OpenStax name, OpenStax logo, OpenStax book covers, OpenStax CNX name, and OpenStax CNX logo are not subject to the Creative Commons license and may not be reproduced without the prior and express written consent of Rice University.

No videos yet!

Click on "Watch later" to put videos here

Problem Solving Explained

In any process improvement endeavor, the initial step involves identifying and bridging gaps between current and desired conditions.

This necessitates effective problem-solving, a continuous process integral to Lean management.

Two key principles guide Lean problem-solving: reliance on verifiable facts, not assumptions, and recognition that it’s an ongoing learning process.

The burden of proof is emphasized, ensuring objectivity.

Additionally, problem-solving is seen as a learning journey during plan implementation, addressing the problem’s cause and implementing countermeasures.

In essence, Lean Manufacturing recognizes problem-solving as vital, emphasizing objective data and continuous learning, enabling organizations to successfully close gaps and achieve continuous improvement.

Tuesday, May 15, 2012

- The Six-Step Problem-Solving Process

- Select the problem to be analyzed

- Clearly define the problem and establish aprecise problem statement

- Set a measurable goal for the problem solving effort

- Establish a process for coordinating with and gaining approval of leadership

- Identify the processes that impact the problem and select one

- List the steps in the process as it currently exists

- Map the Process

- Validate the map of the process

- Identify potential cause of the problem

- Collect and analyze data related to the problem

- Verify or revise the original problem statement

- Identify root causes of the problem

- Collect additional data if needed to verify root causes

- Establish criteria for selecting a solution

- Generate potential solutions that will address the root causes of the problem

- Select a solution

- Gain approval and supporter the chosen solution

- Plan the solution

- Implement the chosen solution on a trial or pilot basis

- If the Problem Solving Process is being used in conjunction with the Continuous Improvement Process, return to Step 6 of the Continuous Improvement Process

- If the Problem Solving Process is being used as a standalone, continue to Step 5

- Gather data on the solution

- Analyze the data on the solution

- Achive the desired results?

- If YES, go to Step 6.

- If NO, go back to Step 1.

- Identify systemic changes and training needs for full implementation

- Adopt the solution

- Plan ongoing monitoring of the solution

- Continue to look for incremental improvements to refine the solution

- Look for another improvement opportunity

4 comments:

Tim, This is a good guideline for any practitioner to follow. I wish I had this a few weeks ago. A client liked a training deck I prepared but didn't want to confuse anyone with terms like Deming Cycle and such. The final version of PDCA was a 6 step process improvement method that's very similar to yours. Thanks for sharing. Cheers, Chris

Thank you for you brief and easy to understand on each step problem solving above.

Wonderful. Well Explained. Thank you for sharing

I mapped this to PDCA and observed that the first 3 steps correspond to P, the next 3 to D, C and A respectively. This Show that indeed planning is the most important step in PDCA.

Search A Lean Journey

Twitter updates.

- Facebook Updates

- Advertising

Subscribe Now

Get new posts by email:

A Lean Journey LinkedIn Group

Recent comments, search this blog.

Top 10 Posts

- Celebrating my 500th Blog Post

- Visual Management Board

- What Do We Mean By True North?

- Guest Post: Reduce, Reuse, Recycle...

- Five Lean Games Every Company Can Benefit From

- 10 Characteristics of a Good Measure and 7 Pitfalls to Avoid

- DOWNTIME and the Eight Wastes

- The 8 Common Wastes in an Office That Cause Downtime

- Lean Leadership: Lessons from Abe Lincoln

Blog Archive

- ► September (5)

- ► August (13)

- ► July (14)

- ► June (12)

- ► May (14)

- ► April (13)

- ► March (13)

- ► February (12)

- ► January (14)

- ► December (11)

- ► November (13)

- ► October (12)

- ► September (13)

- ► July (8)

- ► June (13)

- ► April (12)

- ► February (13)

- ► January (13)

- ► December (12)

- ► October (13)

- ► August (14)

- ► July (13)

- ► May (13)

- ► August (10)

- ► March (14)

- ► December (10)

- ► April (9)

- ► December (13)

- ► October (14)

- ► September (12)

- ► May (12)

- ► January (12)

- ► October (15)

- ► December (14)

- ► November (12)

- ► January (15)

- ► August (17)

- ► July (19)

- ► June (16)

- ► May (19)

- ► April (18)

- ► March (17)

- ► February (16)

- ► January (18)

- ► December (19)

- ► November (18)

- ► October (20)

- ► September (18)

- ► August (22)

- ► July (23)

- ► June (21)

- Lean Roundup #36 – May, 2012

- Meet-up: Beyond Lean's Matt Wrye

- Meet-up: 6 Questions to Learn of Those in Our Comm...

- Memorial Day is a Time for Remembrance

- Lean Quote: Change Leaders Create Constancy of Pur...

- Celebrating A Lean Journey's Third Year With Some ...

- Quality Improvement in Government?

- Webinar: Checking Your Lean Progress

- Lean Quote: Ability, Motivation, Attitude

- Daily Lean Tips Edition #31

- Leveraging Quality to Achieve Your Business Goals

- Lean Quote: Continuous Improvement is About Findin...

- Management Improvement Blog Carnival #166

- Top 3 “Old School” Apps for Lean

- Creating A Quality Focused Culture

- Lean Quote: Opportunity is Dressed as Hard Work

- Kanban Flow - A Free, Fast, & Flexible Kanban Tool

- Demonstrating Commitment Is A Combination of Suppo...

- ► April (17)

- ► February (18)

- ► January (20)

- ► December (18)

- ► November (19)

- ► October (17)

- ► September (22)

- ► July (20)

- ► June (20)

- ► May (21)

- ► April (19)

- ► March (20)

- ► February (17)

- ► January (17)

- ► December (20)

- ► November (15)

- ► August (18)

- ► July (17)

- ► April (14)

- ► November (17)

- ► July (15)

- ► June (9)

- ► May (5)

- A Lean Journey (81)

- A Year Ago (8)

- ASQ's Influential Voices (40)

- Book Review (64)

- Change Management (53)

- Communication (13)

- Conference (10)

- Culture (38)

- Customer Focus (2)

- Daily Management (1)

- Development/Training (13)

- Empowerment (20)

- Engagement (39)

- Exercises/Games (8)

- Facilitation (2)

- Feedback (3)

- Guest Post (168)

- In the News (70)

- Innovation (2)

- kaizen (12)

- L.A.M.E. (5)

- Leadership (226)

- Lean and Green (12)

- Lean Basics (110)

- Lean Definition (25)

- Lean Fun (10)

- Lean in Practice (55)

- Lean Management (152)

- Lean Office (14)

- Lean Products (4)

- Lean Quote (738)

- Lean Resources (44)

- Lean Roundup (202)

- Lean Thinking (5)

- Lean Tips (238)

- Meet-up (35)

- Podcast (5)

- Problem Solving (21)

- Product Review (2)

- Project Management (6)

- Quality (50)

- Quality Magazine (3)

- Respect For People (57)

- Sharing Best Practices (129)

- Soft Skills (3)

- Strategy (6)

- Supply Chain (2)

- Talking Lean (1)

- Teamwork (42)

- Visual Factory (31)

- Webinar (23)

Lean Blogs I Like

- 2 Lean Principles

- 5S Supply Blog

- Avoiding The Corporate Death Spiral

- Be More Careful!

- Curious Cat

- Daily Kaizen

- Evolving Excellence

- Gemba Panta Rei

- Gemba Tales

- Got Boondoggle?

- Gotta Go Lean Blog

- Improve With Me

- Jamie Flinchbaugh

- Kaizen Notebook

- Lean Builder

- Lean Communications

- Lean For Everyone

- Lean Healthcare Exchange

- Lean Homebuilding

- Lean Insider

- Lean Is Good

- Lean Leadership

- Lean Pathways

- Lean Printing

- Lean Reflections

- Lean Simulations

- Lean Six Sigma Academy

- LeanCor Blog

- Learn Lean Manufacturing

- Learning About Lean

- Old Lean Dude Blog

- The A3 Post

- The Lean Edge

- The Lean Library

- The Lean Logistics Blog

- The Lean Thinker

- The Lean Way Consulting

- TimeBack Blog

- To The Gemba

- Training Within Industry

- Visual Management Blog

Other Sites I like

- AME's Target Magazine

- AnythingLean.com

- Art of Lean

- Bosch Rexroth Lean Production

- CIRAS - Theory of Constraints

- Chasing The Rabbit

- Corporate Event Management

- Creative Safety Supply

- Creative Safety Supply 5S Resource Page

- Fuss & O'Neill SPL

- Gemba Academy

- Grassroots Innovation

- IndustryWeek

- Lean Enterprise Institute

- Leanovations

- Learn More McGraw-Hill

- MEP University

- Manufacturers BlogNotions

- Manufacturing Business Technology

- Manufacturing Pulse

- Modern Machine Shop

- Running A Hospital

- Superfactory

- The 5S Store

- Unclutterer

- Visual Workplace

- Xtreme Lean Consulting

- catalyst for change

- freeleansite.com

wibiya widget

A lean journey blog - copyright © 2009-2024 tim mcmahon - all rights reserved.

- Lean Philosophy

Effective Lean Problem Solving

Solving problems in a business setting is an important part of the Lean methodology. Using Lean strategies, a company can better identify what problems exist, pinpoint the root causes, and come up with the right solutions to get the best results. Learning about how to effectively use Lean problem-solving techniques can help any business to improve and become more efficient.

Lean Problem-Solving Process

When working to make improvements in any business setting, it is important to start by identifying problems or potential problems. Solving existing issues is a great way to eliminate waste and improve efficiency very quickly. For many businesses, this is the ideal with to create a competitive edge that will help you to succeed.

When using the lean problem-solving techniques , you will go through a series of steps to get the results that are needed. The steps in the Lean problem-solving process are as follows:

- Identify the Problem – The first thing to do is identify what the actual problem is. This should be as specific as possible and include as many details and other information as is available.

- Break it Down – Breaking the problem down into different steps or parts is critical. This will make it possible to develop the right solutions for each aspect of the problem and help get things running as they should.

- Establish Targets – It is difficult to solve a problem if you don’t know what a working system should look like. Establishing target goals for the system you are working on will help guide you through the rest of the process.

- Look for the Root Cause – No problem can be truly solved without knowing what the root cause is. Keep asking questions about the issue at hand until you discover what is truly causing the issues. This can often be done using the ‘Five Whys’ technique , where you keep asking why something is happening until you reach the root cause.

- Propose Countermeasures – Next, come up with ways that you can address the root cause. This could be one or more different actions that are designed specifically to deal with this issue.

- Implement Countermeasures – Take the countermeasures that are proposed in the previous step and begin testing them. Ideally this can be done in a small test segment, but if needed it can be done in a full production environment. If a solution seems to work in a small system, expand it out to make sure the results scale up as expected.

- Test the Results – Analyze the results by comparing the situation where the problem was found against your target results. If you are able to accomplish the goals identified as your target results, the problem-solving countermeasures are successful. If not, move back to proposing additional countermeasures to get the results you need.

- Standardize – Once you have found a proven way to address the problem at hand, it is time to roll it out to the entire environment. Establishing new processes and procedures that will be followed by everyone in the facility is the last step in the problem-solving process.

Include All Impacted Parties

When going through the Lean problem-solving process it is important to consult with all the parties that are impacted by the problem at hand. It is quite rare that one person will be able to find the best possible solution to a problem, especially if they aren’t the ones who are directly impacted by the issue. Part of the Lean methodology is to work with various teams to come up with the best way of doing things. If you are facing a problem that needs a solution, you will want to include people from various groups such as:

- Front Line Employees – These are typically the people who will deal with the problem on a regular basis. Nobody will have greater insights into the root cause, and potential solutions, than these employees. Having one or more people from this level helping to solve a problem is critical.

- Supervisor – A supervisor or department manager will be able to provide additional insights into how the problem is impacting the business. They will also be the ones to help coordinate the implementation of any potential solutions so they should be involved.

- Appropriate Management – If a problem, or the expected solutions, will require upper level management approval, someone from that team should be included in the process. It is easier to have someone from the leadership partnering with you from the beginning than to try to bring them up to speed for approval down the road.

- Customers – When appropriate, having a customer available to discuss the problem can be very helpful. Customers are sometimes the ones who have the most information about the symptoms of the problem, which can make them very helpful.

Solving problems using Lean methodologies is a great way to help improve efficiency and eliminate waste in any workplace. Having an established process in place will allow you to quickly identify and solve a wide-range of problems in any environment.

Additional Resources

- 8D for Problem Solving – creativesafetysupply.com

- Training to Use 8D Problem-Solving Tactics – blog.creativesafetysupply.com

- Design Thinking: Empathy and Iteration for Innovation and Problem-Solving – creativesafetypublishing.com

- The Great Root Cause Problem Solving Debate – realsafety.org

- “No Problem” is a Problem – jakegoeslean.com

- Lean Six Sigma in small companies, still effective? – lean-news.com

- Lean Manufacturing Implementation – The First 5 Steps – iecieeechallenge.org

- The Lean Method: Go To Gemba and Improve Your Quality Control – blog.5stoday.com

- Applying Hoshin Kanri – 5snews.com

Related posts:

- Total Quality Management And Kaizen Principles In Lean Management

- Why Lean Transformation Fails

- 7 Reasons to Eliminate Waste and Go Lean

- Go Lean – Visual Factory

- Lean Layout Fundamentals

- Why Single Minute Exchange of Die (SMED)?

- Why You Should Use Takt Time Production & How To Do It

- Why Six Sigma Root Cause Analysis is a Great Tool

- Seven Forms of Waste – Lean Six Sigma

The Art of Effective Problem Solving: A Step-by-Step Guide

Whether we realise it or not, problem solving skills are an important part of our daily lives. From resolving a minor annoyance at home to tackling complex business challenges at work, our ability to solve problems has a significant impact on our success and happiness. However, not everyone is naturally gifted at problem-solving, and even those who are can always improve their skills. In this blog post, we will go over the art of effective problem-solving step by step.

Problem Solving Methodologies

Methodology of 8D (Eight Discipline) Problem Solving:

A3 Problem Solving Method:

The A3 problem solving technique is a visual, team-based problem-solving approach that is frequently used in Lean Six Sigma projects. The A3 report is a one-page document that clearly and concisely outlines the problem, root cause analysis, and proposed solution.

Subsequently, in the Lean Six Sigma framework, the 8D and A3 problem solving methodologies are two popular approaches to problem solving. Both methodologies provide a structured, team-based problem-solving approach that guides individuals through a comprehensive and systematic process of identifying, analysing, and resolving problems in an effective and efficient manner.

Step 1 – Define the Problem

By repeatedly asking “ why ,” you’ll eventually get to the bottom of the problem. This is an important step in the problem-solving process because it ensures that you’re dealing with the root cause rather than just the symptoms.

Step 2 – Gather Information and Brainstorm Ideas

Gathering information and brainstorming ideas is the next step in effective problem solving. This entails researching the problem and relevant information, collaborating with others, and coming up with a variety of potential solutions. This increases your chances of finding the best solution to the problem.

Next, work with others to gather a variety of perspectives. Brainstorming with others can be an excellent way to come up with new and creative ideas. Encourage everyone to share their thoughts and ideas when working in a group, and make an effort to actively listen to what others have to say. Be open to new and unconventional ideas and resist the urge to dismiss them too quickly.

Step 3 – Evaluate Options and Choose the Best Solution

Once you’ve compiled a list of potential solutions, it’s time to assess them and select the best one. This is the third step in effective problem solving, and it entails weighing the advantages and disadvantages of each solution, considering their feasibility and practicability, and selecting the solution that is most likely to solve the problem effectively.

You’ll be able to tell which solutions are likely to succeed and which aren’t by assessing their feasibility and practicability.

Step 4 – Implement and Monitor the Solution

When you’ve decided on the best solution, it’s time to put it into action. The fourth and final step in effective problem solving is to put the solution into action, monitor its progress, and make any necessary adjustments.

Finally, make any necessary modifications to the solution. This could entail changing the solution, altering the plan of action, or delegating different tasks. Be willing to make changes if they will improve the solution or help it solve the problem more effectively.

You can increase your chances of success in problem solving by following these steps and considering factors such as the pros and cons of each solution, their feasibility and practicability, and making any necessary adjustments. Furthermore, keep in mind that problem solving is an iterative process, and there may be times when you need to go back to the beginning and restart. Maintain your adaptability and try new solutions until you find the one that works best for you.

Was this helpful?

Daniel croft, 14 principles of the toyota production system: a comprehensive guide, understanding the cost of good quality: investing in quality pays off, understanding process performance: pp and ppk.

Understand Process Performance (Pp) and Process Performance Index (Ppk) to assess and improve manufacturing processes.…

LIFO or FIFO for Stock Management?

Choosing between LIFO and FIFO for stock management depends on factors like product nature, market…

Are There Any Official Standards for Six Sigma?

Are there any official standards for Six Sigma? While Six Sigma is a well-defined methodology…

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

Metodología Lean: ¿qué es y cómo aplicarla en tu empresa?

- Gestión Empresarial

¿Necesitas que los procesos de tu empresa sean más rápidos y eficaces? ¿Quieres diferenciarte de tus competidores y aumentar tu productividad?. La solución está en la metodología Lean. A continuación te contamos en qué consiste esta metodología y cómo aplicarla para mejorar la gestión de tu negocio.

Es fácil soñar con el éxito de una empresa, pero materializar una idea requiere mucho tiempo, dinero y esfuerzo. Sin embargo, ¿qué pensarías si te dijéramos que con la metodología Lean puedes reducir el tiempo, el esfuerzo y la inversión ? Comencemos por saber qué es.

¿Qué es la metodología Lean y cuál es su origen?

La metodología Lean es una forma innovadora de gestionar los procesos de una empresa. Su objetivo es eliminar actividades que no aportan valor , para así poder obtener un producto o servicio de mayor calidad y que mejore la experiencia de los clientes.

Resumiendo, se trata de optimizar los procesos empresariales (productivos y de gestión), con el fin de utilizar menos recursos en los mismos.

Esta filosofía de gestión nació durante los años 80 en Japón bajo el nombre de Lean Manufacturing. Su objetivo era lograr que el proceso de fabricación de vehículos fuese más eficiente.

Tal fue su éxito que se volvió esencial para marcas tan importantes como Toyota, que incluso diseñó un sistema propio, el Sistema de Producción de Toyota (TPS) con estos claros objetivos:

- Identificar sobrecargas en los procesos de producción.

- Eliminar desperdicios (pueden ser de materiales o de tiempo, por ejemplo).

Con la aplicación del TPS, la empresa fabricante de automóviles consiguió optimizar los procesos, reducir los costes, establecer relaciones más fluidas con su entorno y mejorar notablemente su productividad . En definitiva, fue un éxito rotundo.

Con el paso de los años, la metodología Lean se popularizó gracias al libro de Eric Ries titulado “Lean Startup” , donde proponía la aplicación de la filosofía Lean al emprendimiento y a los negocios.

Objetivos de la metodología Lean

La metodología Lean se basa en una serie de objetivos básicos que permiten alcanzar la eficacia:

- Excluir actividades que no agregan valor al producto o servicio.

- Mejorar de forma continua para mantener la calidad del producto o servicio.

- Detectar problemas en origen y solucionarlos.

- Cambiar el enfoque de la empresa para aportar soluciones a los clientes, y no solo venderles productos o servicios.

Por lo tanto, la metodología Lean requiere un cambio estratégico , es decir, una nueva forma de enfocar el negocio para agilizar todos los procesos.

En un entorno de negocios cada vez más competitivo y complejo, los ejecutivos empresariales requieren métodos innovadore s. Se ha comprobado que, manteniendo la administración de procesos industriales en su antiguo status quo, se pierde terreno en el mercado.

En la actualidad, gracias a las tecnologías de la comunicación, implantar un sistema de gestión que provoque un cambio en toda la cultura empresarial se torna más sencillo. Cuanto mejor es la información, mayor es la eficacia que se consigue.

Pasos para aplicar el Lean management a los procesos de tu negocio

La teoría es sencilla, pero la clave está en aplicar correctamente la metodología Lean a tu negocio en el día a día. Los pasos que puedes seguir son los siguientes:

1. Analiza los procesos de tu empresa

Lo primero que vas a tener que hacer es analizar qué procesos se realizan en cada departamento de tu empresa para ver qué pasos le siguen y qué se puede mejorar en cada uno de ellos. Por ejemplo, cuando llega una factura de un proveedor, ¿qué pasos se siguen para procesarla y pagarla?

El análisis de los procesos empresariales se puede dividir en:

- Estratégico: consiste en identificar los recursos necesarios a largo plazo para cumplir con los objetivos de competitividad requeridos.

- Táctico: responde a un proceso metodológico que persigue comparar las distintas alternativas hasta seleccionar la más adecuada. El horizonte de previsión en este caso es a medio y corto plazo.

- Operativo: se basa en la utilización eficiente de los recursos. Requiere un estudio detallado de todas las operaciones que se llevan a cabo en el día a día (en términos de semanas, días y horas empleadas).

2. Elabora la planificación

Cualquier proyecto necesita una definición inicial , es decir, un diagnóstico. Lo mismo ocurre con la implantación de la metodología Lean, y eso es exactamente lo que hemos hecho en el primer paso.

A continuación, una vez que sepas cuáles son los procesos que se pueden mejorar en tu empresa, es el momento de establecer tres cosas:

#1 Los objetivos que quieres alcanzar: deben ser concretos (por ejemplo, aumentar la productividad un 10% en 3 meses), ambiciosos (pero alcanzables) y medibles (para poder cotejar el resultado con el objetivo inicial).

#2 Los recursos que vas a necesitar: se requiere una definición completa de los recursos materiales y personales. ¿Cuántas personas se van a implicar en la aplicación de la metodología?, ¿qué tecnología necesitas? El ERP o la RPA (automatización robótica de procesos) pueden ser grandes aliados para la implantación.

#3 Los plazos que se deben cumplir: para lograr el objetivo final tendrás que establecer metas. Los procesos operativos deben estar previstos para el corto plazo, mientras que la planificación estratégica deberá basarse en un horizonte temporal más dilatado.

3. Involucra a tu equipo, clientes y proveedores

¿Has preguntado a los distintos miembros de tu equipo qué se podría hacer para mejorar sus procesos? ¿Y a tus clientes y proveedores? Sus respuestas te darán información muy valiosa.

Por ejemplo, ¿es posible recibir el material sobre pedido para ahorrar costes de almacenaje ? En este caso se trata de una mejora en el proceso que requiere la colaboración de nuestros proveedores. A través de un sistema de comunicación eficaz se podrán acortar los tiempos de espera para la recepción del material y podremos llegar al objetivo de stock cero.

Otro ejemplo sería contar con información de los clientes, a través de una escucha activa, para ofrecer un producto adaptado a sus necesidades (como se ha dicho anteriormente, mejorar los sistemas de información es la base de implantación del Lean management).

Sea como fuere, es necesario estar conectado con todos los agentes que tienen alguna participación en el desarrollo del negocio.

4. Comienza por lo sencillo

Antes de aplicar la metodología Lean a procesos complejos, comienza por uno que sea sencillo y ve progresando poco a poco. Sin prisa pero sin pausa.

Para evitar estrés en su implantación, la evolución de los procesos y la gestión operativa podrán pasar por diversas fases:

- Fase incipiente: comienzan las primeras pruebas sin que exista un procedimiento estándar. El seguimiento de los procesos es clave para obtener datos.

- Fase de evolución: los procesos comienzan a estandarizarse, así como las normas y responsabilidades asignadas a cada persona. La empresa va definiendo un cuadro de mando para monitorizar las variables a optimizar. Comienza a establecerse una mayor conexión entre todos los agentes internos y externos que intervienen en los procesos.

- Fase de madurez: se obtiene experiencia en la gestión de procesos. Se tiene formación técnica adecuada y se cuentan con las herramientas digitales adecuadas que permitan el desarrollo de la metodología Lean.

- Fase de integración : la empresa está totalmente gestionada dentro de la metodología Lean. Todos sus sistemas permiten relacionarse y compartir información con sus “partners” (tanto internos como externos).

5. Haz seguimiento

De nada sirve implantar una mejora en los procesos y no controlar lo que ocurre después. La monitorización y el seguimiento deben ser continuos para detectar problemas y solucionarlos con rapidez.

En este punto, la empresa también debe contar con herramientas y soluciones que le permitan configurar y mejorar el cuadro de mando del control de procesos.

Básicamente, el seguimiento y control de procesos debe abarcar los siguientes puntos:

- Indicadores de gestión: con los correspondientes objetivos que se quieren lograr (por ejemplo, ratios de productividad, roturas y mermas, obsolescencia de productos, quejas, devoluciones, plazos, etc.).

- Costes: sistema de medición de contabilidad interna (contabilidad de gestión).

- Indicadores de resultados: índices de crecimiento en ventas, clientes, participación en el mercado, etc.

Metodología Lean Startup: analiza de forma sencilla la viabilidad de tu proyecto

La metodología Lean no solo se aplica a procesos de empresas ya en funcionamiento, sino que puede utilizarse también para la validación de una idea de negocio de una startup .

Tradicionalmente, las empresas se creaban siguiendo un esquema básico:

- Elaborar un plan de negocio.

- Solicitar financiación.

- Lanzar el producto o servicio al mercado.

La metodología Lean Startup revoluciona radicalmente el enfoque para lograr que se creen empresas viables con una inversión mínima .

Imagina que con tu nuevo proyecto emprendedor quieres vender un software innovador. La idea es crear un producto mínimo viable (una versión muy sencilla y operativa del software) que se pueda lanzar cuando antes al mercado para testear con clientes reales, si funciona, si les interesa y si estarían dispuestos a pagar por ello (y cuánto).

Esa validación de hipótesi s te permitirá elegir entre varias alternativas:

- Continuar con tu idea inicial y desarrollarla.

- Pivotar y descartar totalmente la idea inicial para crear otra.

- Introducir cambios en la idea inicial para adaptarla a las necesidades reales de los clientes.

De esta forma, aprenderás del mercado y ese aprendizaje es el que va a definir la idea de negocio , todo ello con recursos mínimos.

Y tú, ¿ya has aplicado la metodología Lean a tu negocio? ¡Cuéntanos tu experiencia!

- Últimas entradas

- Metodología Lean: ¿qué es y cómo aplicarla en tu empresa? - 23 de julio de 2019

Manuel Humanes

Estoy interesado en obtener informacion al respecto de este tema.

I’m truly enjoying the design and layout of your blog. It’s a very easy on the eyes which makes it much more enjoyable for me to come here and visit more often. Did you hire out a designer to create your theme? Great work!

Excelente Wrap-up! Me gustó aprender sobre la metodología Lean y cómo aplicarla en la empresa para eliminar bumps y mejorar la eficiencia. ¿Podrías compartir algún ejemplo práctico de donde has aplicado Lean en tus proyectos?

Dejar una respuesta Cancelar la respuesta

Tu dirección de correo electrónico no será publicada. Los campos obligatorios están marcados con *

Correo electrónico *

Guarda mi nombre, correo electrónico y web en este navegador para la próxima vez que comente.

LEI's Learning Portal

Intro to problem solving.

Problem solving is critical to every position in every industry. In this course, you will learn to grasp the situation at the gemba (where the work is done) and use all your senses to understand what is truly happening.

All too often, people create countermeasures to perceived problems without digging deeper, asking the right questions, and thinking more.

Throughout the entirety of the course, we use a case example to illustrate the problem-solving approach as you are learning. In addition, you will deepen your understanding by applying this new way of thinking to a problem of your choice.

This course breaks down lean problem-solving concepts and techniques into simple, easily understood pieces.

How do you solve problems?

Learning objectives.

This course works for people new to the concepts of lean and continuous improvement, for individuals looking to improve their lean understanding and skills, and for organizations wanting to level set the lean knowledge of their workforce to speed progress.

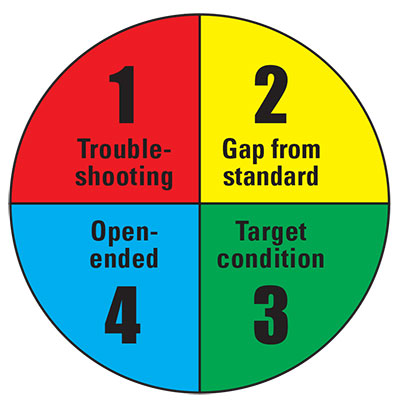

Build a foundational understanding of problem types and problem solvingIdentify the four types of problems

Resolve business challenges by using scientific method, PDCA-based problem solving

Apply A3 thinking to solve problems

Clearly define problems, beginning with grasping the situation at gemba

Learn to break down vague problems to specific problems that can be solved to root cause

Time Estimates Per Unit*

*Actual times may vary.

| Unit 1: Problem Solving | 45 minutes |

| Unit 2: What is an A3? | 2 hours |

| Unit 3: Creating Your A3 | 6.5 hours |

| Work-based Activities | 10+ hours |

Course Units

Expand to view lessons

Course Introduction

0.1 Welcome!

0.2 Platform Tour (optional)

0.3 Copyright Acknowledgment

0.4 Curriculum Concept Map (Visual Syllabus)

0.5 Supplemental Textbook

Unit 1: Lean Problem Solving

1.1.1 | Welcome to Introduction to Problem Solving!

1.1.2 | Lean Transformation Framework

1.1.3 | How We View Problems

1.1.4 | Lead with a Questioning Mindset

1.2.1 | What's a Problem

1.2.2 | Problems Problems Problems

1.2.3 | Four Types of Problems

1.2.4 | Four Types of Problem Solving

1.2.5 | Make the Problem Clear

1.2.6 | Problem Breakdown Analysis

1.2.7 | Unit 1 Personal Reflection

Unit 2: What is an A3?

2.1.0 Helpful information for working on Your A3

2.1.1 | Introduction to A3

2.1.2 | A3 Basics

2.1.3 | Simple A3 Example

2.1.4 | A3 as Good Storytelling

2.1.5 | It's Not a Template

2.1.6 | 5-Step A3 Example

2.1.7 | Your A3: Title and Owner

2.1.8 | Introduction and Chapter 1 (optional)

2.2.1 | Develop Problem Solvers

2.2.2 | Developing Problem Solvers at Herman Miller

2.2.3 | The A3 Process

2.3.1 | Basic Thinking, Mindset, Assumptions

2.3.2 | Porter’s First A3: Rush to a Solution

2.3.3 | Rethinking Thinking by Trevor Maber

2.3.4 | What do I need to know

2.3.5 | Chapter 2: Grasp the Situation—Part 1 (optional)

2.3.6 | Unit 2 Personal Reflection

Unit 3: Your A3

3.1.1 | Grasp the Situation at the Gemba

3.1.2 | Gemba Is More than a Place from Managing to Learn (optional)

3.1.3 | Go See, Ask Why, Show Respect

3.1.4 | Chapter 2: Grasp the Situation—Part 2 (optional)

3.1.5 | Porter’s First Revised A3

3.1.6 | Problem-solving Funnel (Part 1)

3.1.7 | Your A3: Background & Current Condition

3.2.1 | Analysis (part 1)

3.2.2 | Problem-solving Funnel (Part 2)

3.2.3 | Chapter 3: Goals and Analysis—Part 1 (optional)

3.2.4 | Your A3: Background & Current Condition - update

3.2.5 | Analysis (part 2)

3.2.6 | The Five Whys

3.2.8 | The Five Whys Animation

3.2.9 | Problem-solving Funnel (Part 3)

3.2.10 | Your A3: Goal, Target and Analysis

3.3.1 | Choose Countermeasures

3.3.2 | Countermeasures vs. Solutions (optional)

3.3.3 | PICKing Countermeasures

3.3.4 | Your A3: Countermeasures

3.4.1 | Create a Plan

3.4.2 | Nemawashi from Managing to Learn (optional)

3.4.3 | Consensus/Agreement from Managing to Learn (optional)

3.4.4 | From Position Based Authority to Pull-Based Authority (optional)

3.4.5 | Chapter 5: Plan and Followup—Part 1 (optional)

3.4.6 | PDCA from Managing to Learn (optional)

3.4.7 | PDCA Improvement

3.4.8 | Your A3: Plan

3.5.1 | Followup

3.5.2 | Chapter 5: Plan and Followup—Part 2 (optional)

3.5.3 | Detailed A3 Template

3.5.4 | Your A3: Followup

3.5.5 | Conclusion and Getting Started (optional)

3.5.6 | Unit 3 Personal Reflection

3.5.7 | Course Summary

Final Course Survey and Certificate of Completion

Final Course Survey

Certificate of Completion

Continue Your Lean Learning

Extra Resources

More books from the Lean Enterprise Institute

A3 Thinking Questions

More learning experiences from the Lean Enterprise Institute

More on the 'Ladder of Inference'

More on 'Leading with a Questioning Mindset'

About this course

- 0.5 hours of video content

Senior Instructor John Shook

Shook co-authored Learning to See, the book that introduced the world to value-stream mapping. He also co-authored Kaizen Express, a bi-lingual manual of the essential concepts and tools of the Toyota Production System. With Managing to Learn, Shook revealed the deeper workings of the A3 management process that is at the heart of Toyota’s management and leadership.

Worth every minute spent!

Christy leite.

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handlin...

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handling a problem. Problem definition is where most teams fall short. This training covers that well with excellent application examples. Definitely worth taking!

Wish i learned this at the beginning of my career

Jonathan fairweather.

would have saved alot of headake on alot of problem solving arguements ect and got to the root problem

Outstanding

William butdorf.

Very organized and professionally delivered.

It's Not Just a Piece of Paper

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should ...

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should do. Then apply the A3 methodology... I bet you find it isn't one simple problem and you might just discover how complex the problem is, what else is affected that you never realized, or who else might be aware or impacted by it. It's just thinking outside the box and being open to solving the problem. I think to many people don't want to expose a problem because they don't know how to fix it or that it's a failure to have problem at all

Additional Courses

Learning to See Using Value Stream Mapping - with Live Coaching

This workshop shows you how to make and apply this fundamental and critical tool based on the Lean Enterprise Institute's groundbreaking value-stream mapping workbook, Learning to See, which has introduced the mapping tool to thousands of people.

Intro to Lean Thinking & Practice

This online course serves as an introduction to the key concepts, philosophies, and tools associated with lean thinking and practice.

Lean Fundamentals Bundle

Buy all three fundamentals courses at reduced cost. Purchase for yourself or your entire enterprise.

Stay connected on all things lean thinking and practice.

Add your email to LEI's mailing list to get the latest updates.

Please enter a valid email address

Please check this box if you wish to proceed

Oops, something went wrong. Please try again with a different email address.

The Lean Post / Articles / What’s your problem

Problem Solving

What’s your problem

By John Shook

October 31, 2018

You learn through solving problems, failing, reflecting on failure, and adjusting course.

That quote sounds like something from Deming or Toyota. But, no, that’s from that erstwhile problem solver née inventor Steve Jobs.

There may be nothing more fundamental to lean thinking and practice than problem solving . For that matter, there may be nothing more fundamental to being human than problem solving. We breathe, we eat, we create civilizations – we deal with (solve, tackle) problems every step of the way. The lean transformation framework that we at LEI and LGN (Lean Global Network) have been using to frame the challenges of changing ourselves and our organizations in desired directions begins by asking the same question that Toyota begins with: what problem are we trying to solve?

But, to label an activity “problem solving” neither solves any problems nor explains what problem solving even means. It may in fact create some. What is problem solving and how can we do it more effectively? The answer to how we can do it better is “it depends.” But, depends on what?

That’s where Art Smalley’s new book Four Types of Problems comes in with a powerful contribution. Born of Toyota’s problem solving approaches and philosophies, Art’s framework gives us a practical yet profound way to move forward. Let’s consider how it is helpful and ponder how you might use it.

Not every problem looks like this familiar lean classic from Taiichi Ohno in which the problem of a machine breakdown can be tackled via a straightforward root cause analysis:

Sometimes problems are coming at you way too fast to pull out an A3 sized sheet of paper or sit down for a thorough five why causal analysis. Think about a sudden accident and a trip to the ER. Or when your house is on fire. Or when a serious work condition requires attention. Sometimes you need to respond NOW:

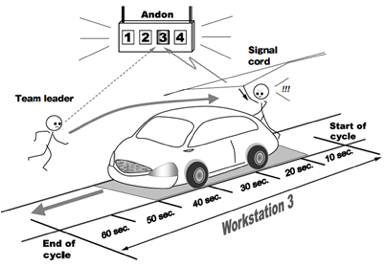

Effective Type One problem solving is much more than merely applying “bandaids”. Toyota’s Jidoka concept informs countless examples of highly structured and effective processes that enable extraordinary levels of operational stability, providing a robust foundation for Type Two root cause analysis when called for.

This illustration explains (to view, click here and come back in seven minutes!) Toyota’s famous “stop-the-line” andon system (technically, the “ fixed-position stop system ”), which embodies a meticulously designed process to enable effective Type One problem solving. To enable flow yet contain any problem or defect, the process engages each worker in identifying and responding to each problem as it occurs; yet despite hundred and even thousands of andon calls each day – with each problem responded to one by one – overall flow is interrupted only a few minutes per shift! Powerful, indeed.

Effectively tackling these types of problems may nor may not require a casual analysis later. If you don’t have these skills at responding to things gone wrong, good luck with your kaizen . As Jim Lancaster reminds us in his book The Work of Management :

“If Lean improvements are not impacting your income statement and you have little time for improvement work, maybe you don’t have an improvement problem, maybe you have a deterioration problem.”

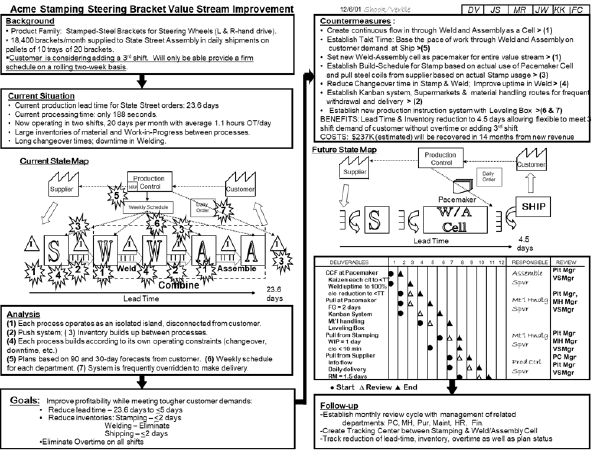

And, not only that, you don’t really want to sit and wait for problems to come at you. You’d like to move from reactive to proactive mode, develop a target condition and take action to learn your way to get there. This is what Acme Stamping did in the classic example from Learning To See ; After a quick mapping exercise revealed the fact that material was moving at a snail’s pace that required about one month to slog through Acme’s operations, yet the actual value creating work time was only about three minutes (ouch), Acme decided to blow up its production process, beginning with a radical transformation of the flows of material and information which necessitated changes in…everything. Spending essentially no money (creativity before capital!), Acme figured out how to reduce lead time from a month to less than a week:

As for Type Four problem solving, think of deciding in 1960 to put a man on the moon by the end of the decade when the path to achieve this loftiest of lofty ambitions was fraught with uncertainty, known and unknown unknowns, and tremendous risk. JFK indeed carried an expansive view of problem solving; consider these words he delivered at American University in 1963 “No problem of human destiny is beyond human beings.”

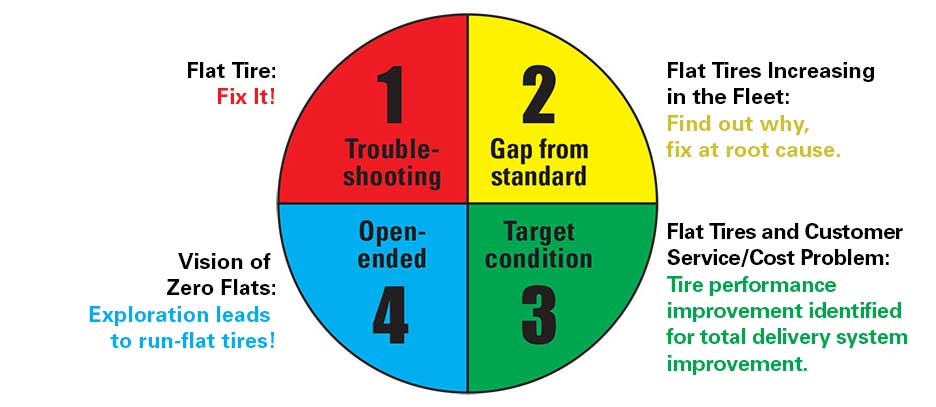

in these four approaches enables an organization to attain stability, sustain gains, and advance steadily towards its goals and visions. The four types in summary:

- Troubleshooting : a reactive process of rapidly (and sometimes temporarily) fixing problems by quickly returning conditions to immediately known standards or normal conditions.

- Gap-from-standard problem solving : solving problems at root cause relative to existing standards or conditions.

- Target-state problem solving : removing obstacles toward achieving a well-defined vision or new and better standards or conditions (i.e., kaizen or continuous improvement ).

- Open-ended problem solving & Innovation : open-ended pursuit of a (perhaps) vision or ideal conditions (new products, processes, services, or systems).

Graphically, you can think of it this way:

In other words, problematic situations can be viewed through different lenses and viewing angles. For example:

No one size fits all in building skills, in coaching others, or in problem solving. There are already way too many hammers running around looking for nails to beat down. The most important contribution of Art’s Four Types categorization is that it provides a self-reflection framework for managers and executives to assess and understand the state of their organization’s problem-solving capability. Does your team (do YOU?) have capability in all four types? Probably not. Surely no one is as strong as they’d like to be across the board. Your team may be very strong in the skills required to perform well in one or two of the types of problem situations and quite weak in the other two. Solid skills across the board will enable you and your team to flourish no matter the kinds of problems that present themselves to you.

With Four Types of Problems , Art Smalley is helping LEI and you in the lean community or anyone working within any team context to address the problems most critical to the long-term health of their organizations—the challenge of how to support the development of better problem-solving organizations and individuals. We know that Four Types of Problems does NOT represent the final word on this important topic. Rather it is the latest step forward in the evolution in a long history of humans trying to solve problems and make things better. As such, our hope is that Four Types will kick off a new round of exploration. And so this particular problem-solving process, for LEI, includes a feedback loop from end users for us to learn what works, what does not work, and how certain tools actually get applied. We look forward to learning how you actually use this book, and with that information we can understand if we have solved our problem.

Related book

Four Types of Problems

by Art Smalley

Written by:

About John Shook

John Shook learned about lean management while working for Toyota for 11 years in Japan and the U.S., helping it transfer production, engineering, and management systems from Japan to NUMMI and other operations around the world. While at Toyota’s headquarters, he became the company’s first American kacho (manager) in Japan.…

Leave a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Revolutionizing Logistics: DHL eCommerce’s Journey Applying Lean Thinking to Automation

Podcast by Matthew Savas

Transforming Corporate Culture: Bestbath’s Approach to Scaling Problem-Solving Capability

Teaching Lean Thinking to Kids: A Conversation with Alan Goodman

Podcast by Alan Goodman and Matthew Savas

Related books

A3 Getting Started Guide

by Lean Enterprise Institute

The Power of Process – A Story of Innovative Lean Process Development

by Eric Ethington and Matt Zayko

Related events

September 26, 2024 | Redmond, WA or Morgantown, PA

Building a Lean Operating and Management System

October 02, 2024 | In-Person (Oakland University in Rochester, MI) OR Coach-Led Online

Managing to Learn

Explore topics.

Subscribe to get the very best of lean thinking delivered right to your inbox

Privacy overview.

IMAGES

VIDEO

COMMENTS

The Four Types of Problems. Type 1: Troubleshooting: reactive problem-solving that hinges upon rapidly returning abnormal conditions to known standards. It provides some immediate relief but does not address the root cause. Type 2: Gap from Standard: structured problem-solving that focuses on defining the problem, setting goals, analyzing the ...

Los 8 pasos para aplicar el PPS o resolución práctica de problemas. Para la aplicación del PPS en la resolución de cualquier problema, se siguen los siguientes pasos: Clarificar el problema. Desglosar el problema. Establecer el objetivo. Analizar la causa raíz. Desarrollar contramedidas.

DMAIC is the problem-solving approach that drives Lean Six Sigma. It's a five-phase method—Define, Measure, Analyze, Improve and Control—for improving existing process problems with unknown causes. DMAIC is based on the Scientific Method and it's pronounced "duh-may-ik.". Originally published on August 24th, 2017, this article was ...

LAS CINCO FASES DEL LEAN. En el post anterior, vimos que el Lean se basa en la eliminación de despilfarros y actividades que no añaden valor a los procesos.. La transformación Lean de una empresa requiere como primer paso identificar qué representa valor para el cliente sea externo o interno. Los esfuerzos de toda la empresa deberán enfocarse en esta dirección, suprimiendo o reduciendo ...

¿Conocías esta metodología para resolver cualquier problema en la organización?Síguenos y da like para más contenido que te ayude a incrementar la productivi...

Select the issue. Search for data to describe the situation. Analyze the facts to obtain root cause (s) of the performance gap. Select a solution. Conduct a pilot test. Evaluate performance. Standardize the gains, reflect, and repeat the process. Let's cover each of these steps in a little more detail. 1.

The process of problem-solving is a methodical approach that involves several distinct stages. Each stage plays a crucial role in navigating from the initial recognition of a problem to its final resolution. Let's explore each of these stages in detail. Step 1: Identifying the Problem. This is the foundational step in the problem-solving process.

The lean problem-solving process is a cycle of observation, assessment, and continual evaluation. As shown in Table 6.1, this cycle typically involves eight specific steps. Steps in the Toyota Lean Problem-Solving Process. Step Action; Step 1: Clarify the problem. Step 2:

Problem-solving is an important component of any business or organization. It entails identifying, analyzing, and resolving problems in order to improve processes, drive results, and foster a culture of continuous improvement. A3 Problem solving is one of the most effective problem-solving methodologies. A3 Problem solving is a structured and systematic approach to problem-solving that ...

This necessitates effective problem-solving, a continuous process integral to Lean management. Two key principles guide Lean problem-solving: reliance on verifiable facts, not assumptions, and recognition that it's an ongoing learning process. The burden of proof is emphasized, ensuring objectivity. Additionally, problem-solving is seen as a ...

Step 1: Identify The Problem. Select the problem to be analyzed. Clearly define the problem and establish aprecise problem statement. Set a measurable goal for the problem solving effort. Establish a process for coordinating with and gaining approval of leadership. Step 2: Analyze The Problem.

The steps in the Lean problem-solving process are as follows: Identify the Problem - The first thing to do is identify what the actual problem is. This should be as specific as possible and include as many details and other information as is available. Break it Down - Breaking the problem down into different steps or parts is critical.