- DOI: 10.1504/IJOR.2018.089734

- Corpus ID: 55030237

A review and reflection on inventory management of perishable products in a single-echelon model

- L. Duong , Lincoln C. Wood , W. Wang

- Published 10 February 2018

- Business, Engineering

- International Journal of Operational Research

Tables from this paper

18 Citations

Discrete event simulation in inventory management, integrating time-temperature dependent deterioration in the economic order quantity model for perishable products in multi-echelon supply chains, effects of consumer demand, product lifetime, and substitution ratio on perishable inventory management, an inventory model for a perishable and recoverable product, two-period pricing and ordering decisions of perishable products with a learning period for demand disruption, a multi-attribute utility theory approach to ordering policy for perishable items, a detailed analysis of use of ai in inventory management for technically better management, a perishable eoq model subject to distinct demands for conforming and non-conforming items, a survey of recent progress in the asymptotic analysis of inventory systems, a methodology to surface aspects of organizational culture to facilitate lean implementation within smes.

- Highly Influenced

54 References

Design of a continuous review stock policy, review of inventory systems with deterioration since 2001, a replenishment policy for perishable products with non-linear holding cost under stochastic supply lead time, integrating deterioration and lifetime constraints in production and supply chain planning: a survey.

- Highly Influential

Production , Manufacturing and Logistics Lost-sales inventory systems with a service level criterion

An approximation to the continuous review inventory model with perishable items and lead times, stock positioning and performance estimation for distribution systems with service constraints, lost-sales inventory theory: a review, stochastic analysis of a continuous review perishable inventory system with positive lead time and poisson demand, comparison between continuous review inventory control systems for perishables with deterministic lifetime and lead time, related papers.

Showing 1 through 3 of 0 Related Papers

- Environment

- Information Science

- Social Issues

- Argumentative

- Cause and Effect

- Classification

- Compare and Contrast

- Descriptive

- Exemplification

- Informative

- Controversial

- Exploratory

- What Is an Essay

- Length of an Essay

- Generate Ideas

- Types of Essays

- Structuring an Essay

- Outline For Essay

- Essay Introduction

- Thesis Statement

- Body of an Essay

- Writing a Conclusion

- Essay Writing Tips

- Drafting an Essay

- Revision Process

- Fix a Broken Essay

- Format of an Essay

- Essay Examples

- Essay Checklist

- Essay Writing Service

- Pay for Research Paper

- Write My Research Paper

- Write My Essay

- Custom Essay Writing Service

- Admission Essay Writing Service

- Pay for Essay

- Academic Ghostwriting

- Write My Book Report

- Case Study Writing Service

- Dissertation Writing Service

- Coursework Writing Service

- Lab Report Writing Service

- Do My Assignment

- Buy College Papers

- Capstone Project Writing Service

- Buy Research Paper

- Custom Essays for Sale

Can’t find a perfect paper?

- Free Essay Samples

- Corporations

The Importance of Inventory Management

Updated 04 September 2023

Subject Corporations

Downloads 49

Category Business

Topic Company

Materials Management

According to De Giovanni, Karray and Martín-Herrán (2019), Materials management refers to the supply of goods at the appropriate quantity and time (p.470). It is important to note that through inventory management, organizations are in a position to minimize operational costs while at the same time meeting customer needs. However, most companies have faced challenges when it comes to materials management.

The primary reason is that there is a close relationship between the inventory maintained by an organization and the income generated by the goods. Moreover, some companies have a huge amount of their invested capital tied up in inventory. For this reason, maintaining a large amount of inventory may lead to obsolescence, price increases, and deterioration of materials. On the other hand, unlike large organizations that have the ability to hold large quantities of inventory, small companies find it costlier.

The Importance of Optimal Stock

According to Gu, Zhang, and Li (2015), there is a need to maintain optimal stock owing to the risks that come with uncertainty (p.107). In particular, uncertainty arises owing to the fact that organizations do not have future information regarding the goods they hold. It is important to note that inventory assists in ensuring the smooth running of the company operations. Therefore, freeing the assets tied up in stocks to come in handy in ensuring the company operations run efficiently. On the other hand, the inventory management models adopted by different companies vary depending on the amount of information available. Optimal materials management minimizes the costs and saves storage space. For this reason, inventory management has a significant impact on the supply chain management of a company.

Forms of Inventory Management

According to Feng, McVay, and Skaife (2014), inventory takes the form of raw materials, finished goods, and work-in-progress (WIP) (p.532). It is important to note that raw materials entail the items supplied to a warehouse without undergoing any conversion process. WIP refers to the form of inventory where it has passed the raw materials stage but is not ready for delivery or sale to the potential buyers. Therefore, there is the need to include the working capital when it comes to the buffer stock, overall production cycle, and the production process. For this reason, there should be minimal quantities of finished goods and raw materials present at the production area whereas the WIP needs to be evaluated closely to determine the duration they take before the goods are ready for sale. The responsibility of conducting this task is solely on the quality control department personnel. Lastly, finished goods are the inventories that are held in the warehouse and are yet to be sold to customers.

Supplier Selection

According to Steinker, Pesch and Hoberg (2016), inventory is one of the current assets and therefore involves the functional areas of the organization such as purchasing, finance, production, and marketing (p.5197). It is important to note that the levels of inventory as determined by the various functional areas of the organization vary. Besides, selecting the appropriate supplier significantly contributes to the success of the company. The primary reason is that there is stiff competition in the market and therefore creating the need for high quality and less costly goods. The factors considered during supplier selection include price, risk, service, and quality.

Concerning the price, the supplier needs to provide the lowest unit price and further provide relatively lower delivery costs and offer bulk discounts. Service depends on whether the goods are fast-moving and thereby the supplier should ensure there are no stock-outs. For this reason, the reliability of the supplier comes in handy during selection. Regarding risk, optimal efficiency in the company operations is subject to supply disruptions. For this reason, companies need to consider the likelihood of the supplier closing down to avoid any potential risks. Lastly, there is the need for quality during supplier selection as it determines the price adopted by the company and reliability of its operations. Hence, poor quality inventory will translate to a reduction in revenues owing to the negative impact on the reputation.

Frequency Needs

According to Tiwari, Daryanto and Wee (2018), the increase in the replenishment frequency paves the way for a significant reduction in the inventory held by an organization (p.287). Moreover, by increasing the replenishment frequency, the company will be in a position to price its goods at the prevailing market amount. However, there are drawbacks associated with increasing the replenishment frequency as there are additional costs associated with placing orders. For this reason, managers of a company need to evaluate the benefits and costs that stem from increasing the replenishment frequency. The costs that go up when the replenishment frequency increases include receipt costs, shipping costs, and ordering costs. On the other hand, capital costs and holding costs decline significantly when the replenishment frequency increases.

Application of Inventory Management to Retail, Leisure, and Manufacturing

According to Steinker, Pesch and Hoberg (2016), the optimal levels of inventory maintained by an organization varies from one firm to another (p.5200). In the case of a retail firm, the primary reason for having high quantities of inventory stem from the fact that the organization does not want interruptions in its operations. Besides, the time gap that exists between the period of ordering and delivery will not enable the completion of a sales opportunity. Similarly, the retail firm may receive bulk discounts from the supplier and thereby leading to large quantities in inventory in a move to optimize profits. On the other hand, the manufacturing companies face a different scenario whereby they not only hold finished good but also work-in-progress and raw materials. The levels of inventory for raw materials maintained by manufacturing firms assist in ensuring the production schedule remains uninterrupted.

Part 2: Field Research Findings

The field research conducted entailed examining the materials management practices exemplified in automobile companies.

Primary Materials Sourcing Method

The primary materials sourcing method used by the automobile companies was a just-in-time inventory system. It is important to note that the just-in-time inventory system assists in ensuring the raw materials from the suppliers get to the purchaser through a direct channel and thereby ensuring the production schedules run smoothly. Moreover, the use of the just-in-time inventory system in the automobile industry production assists in bringing about efficiency as there is a decline in wastes (Shin, Wood and Jun 2016, p.30). On the other hand, there is the need to forecast demand when using the just-in-time inventory management system. The case is different when it comes to the just-in-case inventory supply system as the purchasers have large amounts of goods in inventory that can sustain the market demand.

Consistency of Supply

In the just-in-time supply system, the forwarding of inventory to the various stock points facilitates the delivery to the work centers. Therefore, there are other procedures involved that include verification and validation in a bid to ensure that the supply is consistent with regarding the quality standards and the quantity. In particular, the quality production ensures that the finished goods meet the needs of the customers. However, for the consistency in the supply to be realizable, there is the need for a supply chain that is effective when it comes to the elimination of all non-value-added costs (Tiwari, Daryanto and Wee 2018, p.286). Moreover, the consistency of supply in the just-in-time inventory management system plays a significant role in ensuring the quality of the finished products has the required quality. On the other hand, there are other consistency factors that include manufacturing workmanship and design quality.

Presence or Absence of Stock-outs

The automobile companies use the just-in-time supply management in a bid to minimize the quantities of excess inventory. For this reason, there are instances when the inventory levels lead to stock-outs. In particular, the stock-outs occur during the seasons when the selling of automobiles is at peak (Duong and Wood 2018, p.5341). It is important to note that the just-in-time supply system aims at striking a balance between lowering the holding costs while at the same time meeting the customer demands. On the other hand, stock-outs arise whenever there are late deliveries in the just-in-time supply system. Therefore, late deliveries contribute to delays in the shipments to customers, which is equivalent to stock-outs. Apart from interrupting the operations of the automobile companies, late deliveries tarnish the reputation of the companies. In a move to ensure there are little to no stock-outs, there is the need for a close collaboration between the automobile retailers and suppliers. Hence, there is a possibility of experiencing stock-outs when using the just-in-time supply system, but adopting a high level of synchronization will help to eliminate them.

Stocks of Obsolete Items

Obsolete inventory contributes to increased operating costs. In particular, the obsolete items in inventories of automobile companies arise as a result of the poor design and product quality. Moreover, the poor quality makes the items in inventory fail the quality standard test. The just-in-time supply system may result in stocks of obsolete items if the deliveries made include incomplete goods (Shin, Wood and Jun 2016, p.30). It is important to note that inaccurate forecasting of demand significantly contributes to obsolete items in the inventory. However, the automobile companies have over the years played close attention to the trends and thereby base their decision-making when it comes to just-in-time supply on proven history records. Similarly, the automobile companies manage to avoid obsolete inventory by understanding the needs of the customers.

Part 3: Assessing the Focus Operations

The focus operations of automobile companies benefit from the efficiency, economy, and effectiveness of the just-in-time inventory management.

The just-in-time inventory management is successful if there is efficiency. In particular, the inventory of automobile companies is delivered to the warehouse the period it is needed. Besides, holding excess stock means that there are costs that arise when handling and moving the inventory. Therefore, the arrival of automobile parts when they are required improves the supply operations of companies that operate in this industry (Armenzoni et al. 2015, p.236). Despite the fact that there could be inadequacies in the inventory, the identification of the quantity gap can be filled within a short duration. On the other hand, efficiency in the operations of automobile companies is brought about by the automatic purchasing method which streamlines sourcing of orders and further planning the delivery of the automobile parts.

Effectiveness

The just-in-time inventory management method decreases the wastes that manufacturers incur and therefore showing that the effectiveness of the systems ensures there are no extra costs. It is important to note that the automobile manufactures deliver to warehouses only the needed items, in the appropriate quantity, and at the appropriate time. Moreover, there is a reduction in the overhead expenses which ensures that the overall operation costs remain minimal. Running a warehouse with excess stocks may be expensive for companies owing to the high carrying costs. However, the automobile companies that have adopted the just-in-time inventory management have managed to reduce the number of warehouses they operate, which shows that the just-in-time inventory management system is effective.

The operations of the automobile companies run smoothly owing to the economy brought about by the just-in-time inventory management system. In particular, the global economy is made up of virtual enterprises that are interconnected and thereby placing orders continues to be seamlessly easy. It is important to note that the automobile companies manage to increase their return on investment by lowering the inventories they have in the warehouses (Tiwari, Daryanto and Wee 2018, p.287). On the other hand, the economic benefit that stems from the use of the just-in-time system by the automobile companies also advantages the customers. They get quality products at a fair price since the manufacturers minimize the costs associated with wastes. Despite the expenses that come with implementing the just-in-time inventory system, the benefits outweigh the costs and thereby meeting the performance objectives of the company.

Armenzoni, M., Montanari, R., Vignali, G., Bottani, E., Ferretti, G., Solari, F. and Rinaldi, M., 2015. An integrated approach for demand forecasting and inventory management optimization of spare parts. International Journal of Simulation and Process Modelling, 10(3), pp.233-240.

De Giovanni, P., Karray, S. and Martín-Herrán, G., 2019. Vendor Management Inventory with consignment contracts and the benefits of cooperative advertising. European Journal of Operational Research, 272(2), pp.465-480.

Duong, L.N.K. and Wood, L.C., 2018. Discrete Event Simulation in Inventory Management. In Encyclopedia of Information Science and Technology, Fourth Edition (pp. 5335-5344). IGI Global.

Feng, M., Li, C., McVay, S.E. and Skaife, H., 2014. Does ineffective internal control over financial reporting affect a firm's operations? Evidence from firms' inventory management. The Accounting Review, 90(2), pp.529-557.

Gu, J., Zhang, G. and Li, K.W., 2015. Efficient aircraft spare parts inventory management under demand uncertainty. Journal of air transport management, 42, pp.101-109.

Shin, H., Wood, C.C. and Jun, M., 2016. Does Effective Inventory Management Improve Profitability?: Empirical Evidence from US Manufacturing Industries. International Journal of Information Systems and Supply Chain Management (IJISSCM), 9(3), pp.26-45.

Steinker, S., Pesch, M. and Hoberg, K., 2016. Inventory management under financial distress: an empirical analysis. International Journal of Production Research, 54(17), pp.5182-5207.

Tiwari, S., Daryanto, Y. and Wee, H.M., 2018. Sustainable inventory management with deteriorating and imperfect quality items considering carbon emission. Journal of Cleaner Production, 192, pp.281-292.

Deadline is approaching?

Wait no more. Let us write you an essay from scratch

Related Essays

Related topics.

Find Out the Cost of Your Paper

Type your email

By clicking “Submit”, you agree to our Terms of Use and Privacy policy. Sometimes you will receive account related emails.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

A review and reflection on inventory management of perishable products in a single-echelon model

2018, International Journal of Operational Research

Related Papers

Linh N K Duong

This paper reviews research on single-echelon inventory management of perishable products using the continuous review model. A steady progression of research in this area has included of a range of parameters and is reaching a saturation point where models appear effective and cover a range of realistic situations for single-echelon management. However, research has rested on the assumption that a total cost or profit metric should be used when answering the replenishment questions of when and how much to order. This total cost/profit metric is less appropriate when considering a holistic or systemic modelling of the company where the balance in measurements between departments and the continuous improvement are priority. From this perspective, we outline concerns with existing approaches using a total cost/profit metric when applied to a company. Instead of using approximation methods to optimise total costs/profits in a single department, we assert that managers should focus on multi-metric performance measures to improve system-wide results. In this paper, we present a method to compare the single-echelon replenishment model using multi-metric performance measures and those with the traditional total cost/profit metric.

Perishable products represent a vital area in the retail industry and our daily lives. However, when considered with product substitution (which provides more choices) the short lifetime of perishable products creates significant challenges for the inventory management (e.g., one-third of food products are wasted). The main question is: what is the suitable 'inventory policy' when we have products that are both perishable and substitutable? Appropriate performance metrics are proposed to evaluate the whole system and provide a robust solution while also being easy for professionals to understand and adopt. Therefore, this paper proposes to use multi-metric approach, including Order Rate Variance Ratio, Average Inventory, and Fill Rate. The paper extends inventory theory to consider inventory management of products where they possess multi-period lifetime, positive lead time, required customer service level, and each item is treated separately. Under these circumstances, as the first research adopting these easily captured and analysed performance metrics, the proposed model will enable management of realistic scenarios by incorporating multiple inventory characteristics that support cross-functional continuous improvement.

Giuseppe Vignali

IIE Transactions

Zhaotong Lian

Rigzin Lhamo

Traditional methods for managing the inventory are not 100% applicable in the case of perishable products as they have shorter product life. As a result, perishable need extra attention, otherwise high outdating and lost sales cost, which would contribute hugely for the firms to suffer a huge loss will incur. In this paper, we studied the replenishment policies in each scenario to manage the inventory of perishable products keeping into consideration the age of perishable inventories. We also compared the outcomes of the replenishment policies with and without Backroom and found out how and in what situations one policy could outperform the others in each scenario. The results will show that in an environment, which contain important features of the real-life retail environment, the product age based policies will lead to substantial cost reductions as compared to the ones that does not take the age of inventories into consideration.

Sustainability

William Wang

Industrial Management & Data Systems

LINH NGUYEN DUONG

PurposeThis research proposes a decision framework for using non-financial measures to define a replenishment policy for perishable health products. These products are perishable and substitutable by nature and create complexities for managing inventory. Instead of a financial measure, numerous measures should be considered and balanced to meet business objectives and enhance inventory management.Design/methodology/approachThis research applies a multi-methodological approach and develops a framework that integrates discrete event simulation (DES), analytic hierarchy process (AHP) and data envelopment analysis (DEA) techniques to define the most favourable replenishment policy using non-financial measures.FindingsThe integration framework performs well as illustrated in the numerical example; outcomes from the framework are comparable to those generated using a traditional, financial measures-based, approach. This research demonstrates that it is feasible to adopt non-financial perf...

Shashi Kant Rai, Vrijendra Singh & Anurika Vaish

The present work deals with the supply chain problems related to perishable products. The EOQ model has been used to analyze the data collected and suggest a ordering policy that will minimize the loses and maximize the organizational value. The work provides a suggestion for managers to take decision regarding use of self space and reordering of items depending on the inventory usage.

Journal of Industrial and Management Optimization

Christopher Tang

National Productivity Council

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

RELATED PAPERS

ahmad muhsin

David Perry

Journal of Industrial Engineering International

Saeed Khayatmoghadam

Mohsen Davarynejad

Springer series in operations research

John Muckstadt

IJMSBR Open Access Journal

Journal of Service Science and Management

Yael Perlman

International Journal of Production Economics

Gyula Vastag

Mostafa Gaber

Iie Transactions

Technological and Economic Development of Economy

Mangirdas Morkūnas

Annals of Operations Research

Olga Yakovenko

Production and Operations Management

Marshall Fisher

Mehdi Seifbarghy

sitinurain sangut

elmira gheisariha

IFIP Advances in Information and Communication Technology

Kenn Steger-Jensen

International Journal of Production Research

Mark Ferguson

Manuel Rossetti

Stanisław Krzyżaniak

IJSSIT Publication

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Inventory Management Essays

Leitax: sales and demand forecasting challenges, ai’s transformative influence on retail and personal reflection, fabcos data analysis, optimizing demand planning and inventory management for toffee inc.’s seven star chocolate bar: a case study approach, strategic options for production and inventory management, concepts of operations management, transformative evolution of google company in the digital era, data analytics in the retail industry: uncovering insights for enhanced customer experience, challenges walmart faced during the pandemic and how it streamlined its scm processes during covid-19., inventory process management and control, the importance of considering the level of protection desired when determining spare part quantitiesv, summary of 4 examples of flexibility, demand management plan, walt disney corporation, international procurement management: inventory management, popular essay topics.

- American Dream

- Artificial Intelligence

- Black Lives Matter

- Bullying Essay

- Career Goals Essay

- Causes of the Civil War

- Child Abusing

- Civil Rights Movement

- Community Service

- Cultural Identity

- Cyber Bullying

- Death Penalty

- Depression Essay

- Domestic Violence

- Freedom of Speech

- Global Warming

- Gun Control

- Human Trafficking

- I Believe Essay

- Immigration

- Importance of Education

- Israel and Palestine Conflict

- Leadership Essay

- Legalizing Marijuanas

- Mental Health

- National Honor Society

- Police Brutality

- Pollution Essay

- Racism Essay

- Romeo and Juliet

- Same Sex Marriages

- Social Media

- The Great Gatsby

- The Yellow Wallpaper

- Time Management

- To Kill a Mockingbird

- Violent Video Games

- What Makes You Unique

- Why I Want to Be a Nurse

- Send us an e-mail

Simulation Reflective Report: Inventory Basics Strategy Discussion Report (Assessment)

- To find inspiration for your paper and overcome writer’s block

- As a source of information (ensure proper referencing)

- As a template for you assignment

Adjustable Wrench

Inventory management discussion, reference list.

Various inventory management strategies are available depending on the overall business objective. According to Conley et al. (2019), “[w]ell-designed inventory management strategies are a crucial part of overall supply chain effectiveness” (p. 246). An effective approach requires a system keeping track of the inventory, a reasonable forecast of demand, and reliable estimates of holding, ordering, and shortage costs. This report aims to discuss the strategies implemented for the inventory management exercise involving two products, namely Adjustable Wrench and Rock Salt.

For the first scenario of the operations management simulation, a total of 16 simulations were completed for Adjustable Wrench. Each run involved 12 weeks, and the overall goal was to reduce the total cumulative cost (TCC) at the end of each circle. To achieve optimal outcomes, I implemented a strategy aiming to find order and reorder points that will minimize the total order and holding costs, keeping the customer demand and stockout penalty amount in mind.

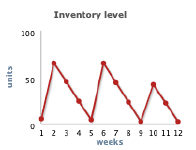

My goal was to keep the order costs, holding costs, and lost opportunity costs at a minimum level since they are generally associated with a significant impact on total inventory costs. Given the fixed order cost for the product of $6.30, regardless of the number of items ordered, I realized that the implementation of the Economic Order Quantity (EOQ) model could be an effective way to reduce the ordering cost. Instead of spending $6.30 weekly, ordering in bulk appeared to be more cost-efficient. With the relatively low holding cost per item ($0.04), the EOQ strategy suggested that 80 Adjustable Wrenches was the optimal order quantity to be purchased over a 4-week period, while the reorder point was found to be 20 Wrenches. As shown in Table 1, the utilization of this strategy allowed for receiving the total cumulative cost of $32.62 during Run 7. Furthermore, Figure 1 demonstrates the inventory level obtained for the simulation with the optimal TCC.

Table 1: Adjustable Wrench Simulations

| Run | Order Size Units | Reorder Point Units | W1 | W2 | W3 | W4 | W5 | W6 | W7 | W8 | W9 | W10 | W11 | W12 | Holding Cost | Order cost | Stockout Cost | TCC |

| 1 | 60 | 20 | 0.2 | 1.8 | 1 | 0.24 | 1.88 | 1.08 | 0.24 | 1.8 | 1.04 | 0.28 | 1.08 | 0.24 | $10.88 | $25.20 | $0.00 | |

| 2 | 100 | 20 | 0.24 | 3.44 | 2.6 | 1.72 | 0.92 | 0.16 | 3.36 | 2.56 | 1.72 | 0.96 | 0.12 | 0.16 | $17.96 | $18.90 | $0.00 | |

| 3 | 40 | 20 | 0.2 | 0.96 | 0.2 | 0.8 | 0.04 | 0.8 | 0 | 0.84 | 0.08 | 0.84 | 0.04 | 0.04 | $4.84 | $6.30 | $0.00 | |

| 4 | 240 | 25 | 0.16 | 8.92 | 8.08 | 7.24 | 6.44 | 5.6 | 4.76 | 3.96 | 3.16 | 2.32 | 1.52 | 0.72 | $52.88 | $50.40 | $0.00 | |

| 5 | 20 | 20 | 0.28 | 0.28 | 0.28 | 0.36 | 0.28 | 0.24 | 0.24 | 0.16 | 2.52 | 1.76 | 0.96 | 0.16 | $7.52 | $56.70 | $0.00 | |

| 6 | 20 | 20 | 0.2 | 0.2 | 0.24 | 0.24 | 0.24 | 0.24 | 0.2 | 0.16 | 1.04 | 0.28 | 1.12 | 0.36 | $4.52 | $18.90 | $0.00 | |

| 7 | 80 | 20 | 0.2 | 2.6 | 1.8 | 0.96 | 0.16 | 2.6 | 1.76 | 0.92 | 0.08 | 1.86 | 0.88 | 0.08 | $13.90 | $18.90 | $0.00 | |

| 8 | 75 | 20 | 0.2 | 2.44 | 1.6 | 0.8 | 0.04 | 2.24 | 1.4 | 0.64 | 1.76 | 0.92 | 0.08 | 0.12 | $12.24 | $25.20 | $0.00 | |

| 9 | 40 | 25 | 0.16 | 0.96 | 0.2 | 1 | 0.2 | 1 | 0.24 | 1.04 | 0.24 | 1.88 | 1.08 | 0.28 | $8.28 | $31.50 | $0.00 | |

| 10 | 60 | 20 | 0.16 | 1.84 | 1.04 | 0.32 | 1.64 | 0.84 | 0.04 | 1.56 | 0.8 | 0.04 | 0.76 | 0.04 | $9.08 | $31.50 | $0.00 | |

| 11 | 80 | 20 | 0.16 | 2.52 | 1.68 | 0.92 | 0.08 | 2.56 | 1.8 | 0.96 | 0.12 | 1.64 | 0.8 | 0 | $13.24 | $18.90 | $20.00 | |

| 12 | 80 | 20 | 0.2 | 2.68 | 1.92 | 1.08 | 0.28 | 2.24 | 1.6 | 0.72 | 3.16 | 2.4 | 1.64 | 0.76 | $18.68 | $18.90 | $0.00 | |

| 13 | 80 | <20 | 0.2 | 2.6 | 1.76 | 0.92 | 0.12 | 2.44 | 1.86 | 0.88 | 0.16 | 1.52 | 0.64 | 0.08 | $13.18 | $25.20 | $0.00 | |

| 14 | 60 | <20 | 0.24 | 1.76 | 0.92 | 0.08 | 1.6 | 0.84 | 0.08 | 2.44 | 1.68 | 0.84 | 0 | 0.12 | $10.60 | $25.20 | $20.00 | |

| 15 | 50 | <20 | 0.16 | 1.76 | 1 | 0.2 | 1.64 | 0.8 | 0.04 | 2.44 | 1.6 | 0.76 | 1.76 | 0.96 | $13.12 | $25.20 | $0.00 | |

| 16 | 60 | 21 | 0.2 | 1.84 | 0.96 | 0.08 | 1.6 | 0.84 | 0.04 | 2.48 | 1.68 | 0.84 | 0.08 | 0.12 | $10.76 | $25.20 | $0.00 |

Similar to the Adjustable Wrench simulation, the Rock Salt simulations were derived upon the ordering and holding costs, as well as consumer demand anticipation. A total of 20 simulations were run to achieve the optimal solution. At the same time, it was evident that the primary difference between the two scenarios was due to standard deviation. The Rock Salt simulation was marked by a higher standard deviation of 9, while the Adjustable Wrench simulation was characterized by a standard deviation of 1. In other words, the consumer demand could be below or above the average mean. Such a characteristic indicated that incorrect forecasting of demand for Rock Salt was possible. In turn, inaccurate forecasts can result in a decrease in working capital and inventory, missed revenues, and excess materials (Gupta, 2020). Given the order cost of $6.30 and an increase in the holding cost to $0.07, I decided to apply a similar strategy based on the EOQ model for Rock Salt.

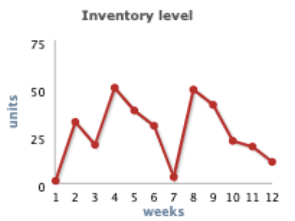

This approach proved to be effective by establishing the optimal total cost of 60 units of Rock Salt ordered every three weeks. Following the principle of economies of scale, it was evident that buying in bulk was more cost-efficient than weekly purchases. At the same time, while I aimed to reduce ordering costs, I increased the holding costs due to the standard deviation of 9 for the given product. As shown in Table 2, Run 3 with an order size of 60 units and reorder point of 30 units resulted in the total cumulative costs of $51.80. Similarly, run 16 resulted in a TCC of $53.62, which supports the suggestion of 60 units for order size and 30 units for reorder point. Figure 2 presents the inventory level chart for the run with the lowest TCC level.

Table 2: Rock Salt Simulations

| Run | Order Size Units | Re-order Point | W1 | W2 | W3 | W4 | W5 | W6 | W7 | W8 | W9 | W10 | W11 | W12 | Holding Cost | Order cost | Stockout Cost | |

| 1 | 80 | 40 | 0.91 | 1.47 | 0 | 4.62 | 3.43 | 1.12 | 5.76 | 4.2 | 2.31 | 2.17 | 4.2 | 3.92 | $34.11 | $31.50 | $20.00 | |

| 2 | 120 | 30 | 1.12 | 7.77 | 6.93 | 6.09 | 4.27 | 4.27 | 3.36 | 2.73 | 1.89 | 2.03 | 0 | 2.45 | $42.91 | $25.20 | $0.00 | |

| 3 | 60 | 30 | 1.05 | 2.73 | 0.98 | 4.06 | 2.59 | 2.24 | 1.12 | 6.65 | 5.46 | 3.64 | 2.31 | 0.07 | $32.90 | $18.90 | $0.00 | |

| 4 | 160 | 40 | 1.26 | 11.41 | 10.64 | 9.1 | 7.28 | 5.6 | 5.11 | 4.06 | 3.15 | 2.52 | 0.21 | 1.26 | $61.60 | $12.60 | $0.00 | |

| 5 | 240 | 40 | 0.77 | 16.8 | 15.54 | 14.21 | 12.6 | 10.22 | 8.4 | 8.12 | 6.86 | 5.04 | 3.36 | 1.54 | $103.46 | $6.30 | $0.00 | |

| 6 | 40 | 22 | 0.7 | 2.59 | 0.84 | 3.15 | 0.42 | 2.24 | 0.84 | 4.55 | 2.87 | 1.54 | 1.12 | 0 | $20.86 | $37.80 | $20.00 | |

| 7 | 60 | 30 | 0.56 | 3.08 | 2.66 | 1.61 | 4.97 | 3.5 | 1.33 | 6.3 | 4.83 | 2.59 | 1.4 | 1.19 | $34.02 | $25.20 | $0.00 | |

| 8 | 100 | 50 | 0.21 | 4.27 | 1.96 | 6.72 | 6.23 | 5.39 | 3.01 | 0.35 | 3.92 | 2.52 | 0 | 0.21 | $34.79 | $25.20 | $20.00 | |

| 9 | 60 | 40 | 0.42 | 4.34 | 2.94 | 0.42 | 3.71 | 1.96 | 4.62 | 3.63 | 1.05 | 6.3 | 4.55 | 3.22 | $37.16 | $25.20 | $0.00 | |

| 10 | 100 | 40 | 0.56 | 6.37 | 5.11 | 3.92 | 1.61 | 6.93 | 4.2 | 2.38 | 7.77 | 6.51 | 4.27 | 3.36 | $52.99 | $18.90 | $0.00 | |

| 11 | 40 | <20 | 0.77 | 1.19 | 0.91 | 3.71 | 2.03 | 0.63 | 2.03 | 1.82 | 2.1 | 0.14 | 2.03 | 0.14 | $17.50 | $44.10 | $0.00 | |

| 12 | 60 | <20 | 1.12 | 4.13 | 3.15 | 0.91 | 4.27 | 1.61 | 3.85 | 1.96 | 4.41 | 2.52 | 0.07 | 1.54 | $29.54 | $31.50 | $0.00 | |

| 13 | 200 | 23 | 0.56 | 13.79 | 12.6 | 11.97 | 11.69 | 10.01 | 9.03 | 8.82 | 8.12 | 6.23 | 5.25 | 4.06 | $102.13 | $6.30 | $0.00 | |

| 14 | 20 | 20 | 1.26 | 0.98 | 1.4 | 1.12 | 3.29 | 2.66 | 0 | 3.15 | 1.89 | 2.8 | 1.33 | 2.73 | $22.61 | $44.10 | $0.00 | |

| 15 | 60 | <20 | 1.47 | 4.06 | 3.5 | 2.52 | 2.52 | 0.49 | 1.33 | 2.45 | 0.28 | 2.87 | 1.33 | 2.1 | $24.92 | $31.50 | $0.00 | |

| 16 | 60 | 30 | 0.07 | 2.24 | 1.4 | 3.5 | 2.66 | 2.1 | 0.21 | 3.43 | 2.87 | 1.54 | 1.33 | 0.77 | $22.12 | $31.50 | $0.00 | |

| 17 | 60 | 35 | 1.05 | 4.34 | 2.59 | 1.4 | 2.17 | 0.63 | 0.84 | 0.98 | 4.13 | 1.89 | 0.21 | 0 | $20.23 | $37.80 | $20.00 | |

| 18 | 40 | 25 | 0.91 | 3.08 | 2.24 | 0.21 | 2.94 | 1.82 | 0.63 | 0.98 | 0.56 | 0.56 | 0.21 | 0 | $14.14 | $44.10 | $20.00 | |

| 19 | 40 | <20 | 0.21 | 0.77 | 2.03 | 0.35 | 0.49 | 1.33 | 5.39 | 5.25 | 4.62 | 4.62 | 2.73 | 2.38 | $30.17 | $31.50 | $0.00 | |

| 20 | 40 | 22 | 0.91 | 1.75 | 0 | 1.54 | 0 | 1.12 | 0.98 | 0.77 | 0.28 | 0.56 | 1.05 | 0.56 | $9.52 | $56.70 | $20.00 |

Upon the completion of the Inventory Management simulation, I confirmed that my ideas of the primary concepts were correct. The inventory costs that can significantly impact the business regardless of its scope and area include the order, holding, and lost opportunity costs (Konior and Szóstak, 2020). Hence, during the simulations, I aimed to keep these indicators low while keeping in mind the importance of customer demand to the outcomes. Maintaining the optimal stock is essential for effective inventory management, while the utilization of EOQ and economies of scale allow for appropriate budget allocation (Mittal and Shah, 2016). The application of these frameworks assisted me in reaching a low TCC level.

I can conclude that based on my simulation results presented in Tables 1 and 2, the EOQ determines the size of the order by establishing the optimal amount required at the lowest price possible. At the same time, the risk of stock loss and excessive order affect the order size as well (Patterson, 2021). The simulations for Adjustable Wrench and Rock Salt have indicated that ordering in bulk is cost-efficient when the order cost is fixed. However, standard deviation must be considered, as in the case with Rock Salt since it increases the holding costs.

Conley, K. et al. (2019) ‘Effect of accounting policies on effectiveness of inventory management strategies’, Engineering Management Journal , 31(4), pp. 246-256. doi:10.1080/10429247.2019.1652056

Gupta, S. (2020) Working capital management through inventory management techniques . Raleigh: Lulu Publication.

Konior, J. and Szóstak, M. (2020) ‘Methodology of planning the course of the cumulative cost curve in construction projects’, Sustainability , 12(6), pp. 1-22. doi:10.3390/su12062347

Mittal, M. and Shah, N. H. (eds.) (2016) Optimal inventory control and management techniques . Hershey: IGI Global.

Patterson, A. M. (2021) Three strategies for inventory management in a small business . Web.

- Nike's Organizational Strategic Management

- Tesla Inc.'s Business Strategy Analysis

- "The Monkey Wrench Gang" by Edward Abbey

- Adjustable Speed Drives Improving Circulating Water System

- Environmental Problems in Literary Fiction

- Sustainable Transportation and United Nations’ Goal

- Service Recovery and Customer Forgiveness

- Digital Strategy for MD Now Urgent Care

- Stability and Predictability of Regulatory Environment

- Diversicare Healthcare Analysis and Strategic Goals

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2023, February 13). Simulation Reflective Report: Inventory Basics Strategy Discussion. https://ivypanda.com/essays/simulation-reflective-report-inventory-basics-strategy-discussion/

"Simulation Reflective Report: Inventory Basics Strategy Discussion." IvyPanda , 13 Feb. 2023, ivypanda.com/essays/simulation-reflective-report-inventory-basics-strategy-discussion/.

IvyPanda . (2023) 'Simulation Reflective Report: Inventory Basics Strategy Discussion'. 13 February.

IvyPanda . 2023. "Simulation Reflective Report: Inventory Basics Strategy Discussion." February 13, 2023. https://ivypanda.com/essays/simulation-reflective-report-inventory-basics-strategy-discussion/.

1. IvyPanda . "Simulation Reflective Report: Inventory Basics Strategy Discussion." February 13, 2023. https://ivypanda.com/essays/simulation-reflective-report-inventory-basics-strategy-discussion/.

Bibliography

IvyPanda . "Simulation Reflective Report: Inventory Basics Strategy Discussion." February 13, 2023. https://ivypanda.com/essays/simulation-reflective-report-inventory-basics-strategy-discussion/.

IvyPanda uses cookies and similar technologies to enhance your experience, enabling functionalities such as:

- Basic site functions

- Ensuring secure, safe transactions

- Secure account login

- Remembering account, browser, and regional preferences

- Remembering privacy and security settings

- Analyzing site traffic and usage

- Personalized search, content, and recommendations

- Displaying relevant, targeted ads on and off IvyPanda

Please refer to IvyPanda's Cookies Policy and Privacy Policy for detailed information.

Certain technologies we use are essential for critical functions such as security and site integrity, account authentication, security and privacy preferences, internal site usage and maintenance data, and ensuring the site operates correctly for browsing and transactions.

Cookies and similar technologies are used to enhance your experience by:

- Remembering general and regional preferences

- Personalizing content, search, recommendations, and offers

Some functions, such as personalized recommendations, account preferences, or localization, may not work correctly without these technologies. For more details, please refer to IvyPanda's Cookies Policy .

To enable personalized advertising (such as interest-based ads), we may share your data with our marketing and advertising partners using cookies and other technologies. These partners may have their own information collected about you. Turning off the personalized advertising setting won't stop you from seeing IvyPanda ads, but it may make the ads you see less relevant or more repetitive.

Personalized advertising may be considered a "sale" or "sharing" of the information under California and other state privacy laws, and you may have the right to opt out. Turning off personalized advertising allows you to exercise your right to opt out. Learn more in IvyPanda's Cookies Policy and Privacy Policy .

To install StudyMoose App tap and then “Add to Home Screen”

Apple vs. Dell: Inventory Management Analysis

Save to my list

Remove from my list

Apple vs. Dell: Inventory Management Analysis. (2016, Apr 03). Retrieved from https://studymoose.com/inventory-management-essay

"Apple vs. Dell: Inventory Management Analysis." StudyMoose , 3 Apr 2016, https://studymoose.com/inventory-management-essay

StudyMoose. (2016). Apple vs. Dell: Inventory Management Analysis . [Online]. Available at: https://studymoose.com/inventory-management-essay [Accessed: 18 Sep. 2024]

"Apple vs. Dell: Inventory Management Analysis." StudyMoose, Apr 03, 2016. Accessed September 18, 2024. https://studymoose.com/inventory-management-essay

"Apple vs. Dell: Inventory Management Analysis," StudyMoose , 03-Apr-2016. [Online]. Available: https://studymoose.com/inventory-management-essay. [Accessed: 18-Sep-2024]

StudyMoose. (2016). Apple vs. Dell: Inventory Management Analysis . [Online]. Available at: https://studymoose.com/inventory-management-essay [Accessed: 18-Sep-2024]

- Who Makes the Apple iPhone: Apple Outsourcing Analysis? Pages: 3 (763 words)

- Dell Supply Chain Management Pages: 17 (5003 words)

- Apple Watch: Complexity, Trialability And Observability Of The First Wearable Device By Apple Pages: 3 (714 words)

- Channel of Distribution Analysis of Dell & HP Pages: 11 (3054 words)

- SWOT Analysis on Dell Business Model Pages: 3 (841 words)

- Analysis Of Scientific Glass Inventory Management Finance Pages: 9 (2688 words)

- Five Forces Framework in Personal Computer Industry (DELL) Pages: 8 (2231 words)

- Dell's Working Capital Case Solution Pages: 9 (2619 words)

- Organizational Culture at Dell Pages: 8 (2136 words)

- Dell 4p's of the Marketing Mix Pages: 13 (3649 words)

👋 Hi! I’m your smart assistant Amy!

Don’t know where to start? Type your requirements and I’ll connect you to an academic expert within 3 minutes.

IMAGES

VIDEO

COMMENTS

study of the existing inventory management strategy employed by the case company. First, a comprehensive understanding of the case company's inventory management is developed through a current state analysis, and the factors causing inefficient inventory management are identified. Then, methods for optimising inventory management are recommended to

projects on distribution management systems, inventory management, and production This is a copy of the 'post - print' (i.e., final authors' copy, after refere e comments have been addre ssed):

This study presents implementing and evaluating a computer vision platform to optimize warehouse inventory management. Integrating machine learning and computer vision technologies, this solution addresses critical challenges in inventory accuracy and operational efficiency, overcoming the limitations of traditional methods and pre-existing automated systems.

2.4.2. Inventory management practices and organizational competitiveness. Inventory management is very crucial to any organization that is improving on its performance and attaining high levels of customer satisfaction. According to Nzuza (Citation 2015), the material held by an organization makes up for most of the organization assets. Most ...

DOI: 10.1504/IJOR.2018.089734 Corpus ID: 55030237; A review and reflection on inventory management of perishable products in a single-echelon model @article{Duong2018ARA, title={A review and reflection on inventory management of perishable products in a single-echelon model}, author={Linh Nguyen Khanh Duong and Lincoln C. Wood and William Yu Chung Wang}, journal={International Journal of ...

Materials Management. According to De Giovanni, Karray and Martín-Herrán (2019), Materials management refers to the supply of goods at the appropriate quantity and time (p.470). It is important to note that through inventory management, organizations are in a position to minimize operational costs while at the same time meeting customer needs.

A review and reflection on inventory management of perishable products 17 Olsson, F. and Tydesjö, P. (2010) 'Inventory problems with perishable items: fixed lifetimes and backlogging', European Journal of Operational Research, Vol. 202, No. 1, pp.131-137, doi: 10.1016/j.ejor.2009.05.010.

Inventory management plays a pivotal role in modern business operations, impacting operational efficiencies, financial security, and competitive advantages. This essay explores the ...

Abstract. Inventory is a central management function. It is a cornerstone of supply chain management and logistics in the material management system. Depending on the organisational objectives ...

A review and reflection on inventory management of perishable products in a single-echelon model ... and guides further research, e.g., multi-echelon modeling. The (s, S) replenishment model is most common, used in 14 papers. The vector of inventory ages is a Markov chain, and it is relatively simple to construct an approximation for this model ...

Inventory Management Essays. Leitax: Sales and Demand Forecasting Challenges ... AI's Transformative Influence on Retail and Personal Reflection. ... The inventory management process involves moving a product from the raw materials to the storage, end product, and point of sale (Priniotakis & Argyropoulos, 2018). ...

incremental ones. In this case, the inventory serves to compensate for the differences between the productive potential and the demand volume (Lukáš 2009). The goal of the paper is to critically review methods of Inventory management theory. The scope of this paper is based on collection of methods which were derived form a comprehensive work

5Yomlead Enterprise. n, Ibukunoluwa Hannah, Phone; +2348067443099, E-mail; [email protected]: This study focuses on the effects of inventory management sy. tem on organization performance of selected stores and supermarket in Osogbo, Osun State. The objectives of this study are to: determine the effect of inventory ...

EOQ is a technique for inventory management that minimizes ordering and holding costs for the year. EOQ is a crucial accounting formula that determines when the combination of inventory carrying cost, order and costs are the least (Simchi et al., 2003). The result obtained from the formula gives the most effective quality to order.

Improved customer service. Reduce inventory investment. To increased productivity of business (Stylus, 2008) Benefits of inventory management (Stylus, 2008): Inventory management systems can help reduce the time to respond to changing market demand of products and can help control excess stock.

Simulation Reflective Report: Inventory Basics Strategy Discussion Report (Assessment) Various inventory management strategies are available depending on the overall business objective. According to Conley et al. (2019), " [w]ell-designed inventory management strategies are a crucial part of overall supply chain effectiveness" (p. 246). An ...

2 Be mindful of length. Generally, five hundred to one thousand words is an appropriate length for a reflective essay. If it's a personal piece, it may be longer. You might be required to keep your essay within a general word count if it's an assignment or part of an application.

Inventory management in a healthcare system needs to be compatible with its operations and critical characteristics ensuring minimization of inventory-related cost as well as maximization of ...

The aim of inventory management is based on the effectiveness from processes. Some advantages of an inventory management system are: meet customer demands, prevent loss of sales, and be prepared to meet unpredicted increase in actual demands. Even though, there still some disadvantages that we need to consider such as the money invested ...

The two reputable multinational corporations that are focused in this assignment are Apple Inc. (Apple) and Dell Inc. (Dell). These two companies manage inventory as part of their daily business operations. Apple was started in 1976 by Ronald Wayne, Steve Wozniak and Steve Jobs. The company is a major multinational corporation and its ...